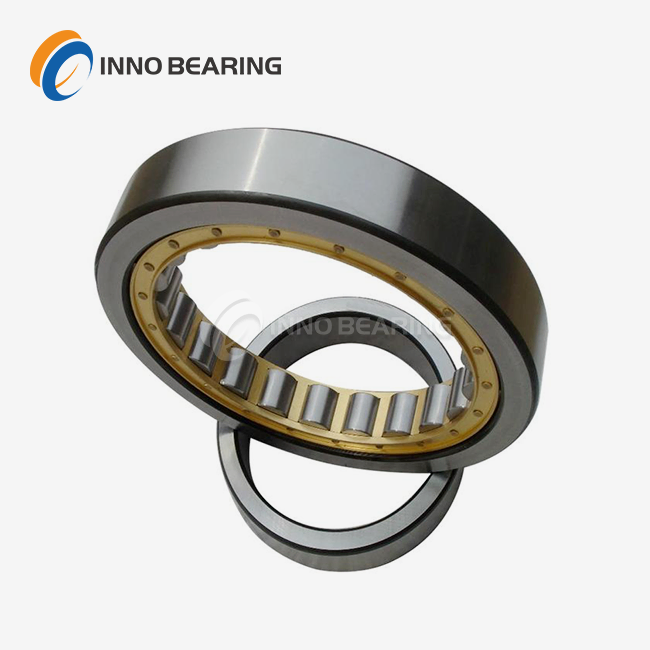

OEM makers around the world are choosing Chinese slewing ring bearing sources more and more because they offer the best mix of modern production skills, low costs, and quick customization services. China has become the world leader in making high-quality Slewing Bearings that meet strict international standards and are priced reasonably. Chinese suppliers like INNO Bearing make precision-engineered parts for wind turbines, big machinery, and industry uses. They have decades of experience in their field. They are the best choice for OEMs looking for reliable turntable bearing partners because they can handle complicated design needs, keep quality under tight control, and provide reliable supply lines.

Understanding OEM/ODM Excellence in Slewing Bearing Manufacturing

The world market for slewing bearings needs complex production agreements that do more than just offer products. OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) partnerships are now necessary for businesses that are making wind farms, building equipment, and big machinery. Through these agreements, brands can use specialized knowledge while still keeping their own unique place in the market.

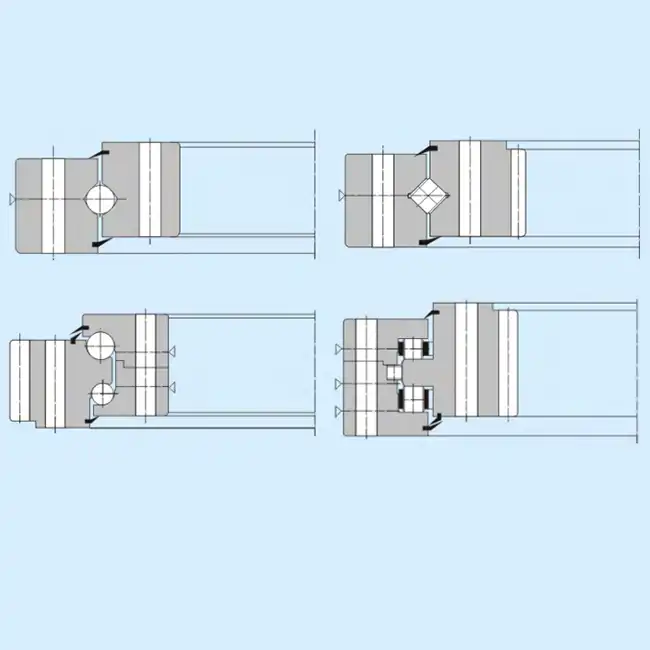

In the rotary bearing business, deep tailoring is very important because each application has its own problems. Manufacturers of wind turbines need bearings that can work for decades without any upkeep and in all kinds of weather. OEMs of construction tools need heavy-duty bearings that can handle huge axial and rotational loads while still working perfectly.

Chinese providers do well in this setting because they provide full scientific support, advanced metalworking skills, and flexible production systems. Because they can quickly change to meet new requirements while keeping quality high, they have changed the way OEMs buy bearings and make new products.

Our Comprehensive OEM/ODM Manufacturing Strengths

Because we've been in the business for 30 years, INNO Bearing has unmatched OEM/ODM skills that make us stand out in the precision bearing market. Our factory can make bearings with a width of up to φ5000mm, which puts us in a unique situation to serve a wide range of industrial needs, from crane systems to offshore drilling platforms.

Our research and development includes advanced materials science, such as the creation of special steel alloys like 42CrMo and 50Mn that are very resistant to wear. Our quality control systems use strict testing methods, such as spectrographic analysis to fully track materials and wear proof after more than 500,000 cycles. This makes sure that every thrust bearing meets the exact requirements for load capacity and service life.

Supply chain quality is still very important for OEM partnerships. Our flexible manufacturing method cuts down on production time by 30% while still meeting ISO 9001 standards. We keep strategic warehouse spots around the world, which lets us ship standard models within 48 hours and deliver special large-scale projects within 15 to 20 days.

Our production mindset is based on scalability. No matter if we're making high-volume sealed bearings for building equipment or specialized gear bearings for aircraft uses, our production systems are flexible enough to handle changing demand patterns without affecting quality or delivery times.

Advanced Customization Options for Every Application

We can make slew ring bearing products in a wide range of sizes, which is the first step in customizing the physical form. The outside diameters of our rings range from 100 mm to 4000 mm, the inside diameters from 80 mm to 3800 mm, and the heights from 8 mm to 150 mm. Because it is so flexible, it can be perfectly fitted to a wide range of uses, from small medical equipment to huge mining equipment.

Improvements to functional features include different binding choices that use nitrile rubber for normal uses or fluororubber for areas with high temperatures and oil resistance. Our triple-lip seal designs offer IP67 protection against tough conditions, which increases the life of bearings in coastal and ocean settings where rust resistance is important.

IoT sensor ports for predictive maintenance systems are one example of technological integration skills. These ports allow real-time tracking of bearing performance in wind turbine uses. Our tech team works with OEMs to add smart features that make equipment more reliable and lower its running costs.

Customizing your brand is more than just marking it. We offer full package Solutions, customized technical documents, and private labeling services that make sure the brand stays the same all the way through the supply chain.

Compliance licenses are different for each type of business and use. Our goods are certified by DNV-GL for use in naval settings and meet API 6A standards for use in oil and gas uses. They are also marked with the CE mark for use in European markets, which makes it easy for them to fit into OEM product lines around the world.

The Strategic ODM Advantage for Innovation

Through ODM agreements, new, cutting-edge slewing ring bearing solutions that push the limits of the industry can be co-created. Our engineering team works directly with OEM partners to find new market needs and create next-generation goods that give us an edge over our competitors.

Some of ODM's recent wins include making ultra-low noise bearings that work below 35dB for medical imaging equipment and ceramic-coated options for use in temperatures above 150°C. These new ideas show how smart relationships can shorten the time it takes to make a product while also cutting the costs of research and development for OEM partners.

Protecting intellectual property is still the most important thing in ODM interactions. Our privacy rules and deals to share patents protect new designs while letting everyone benefit from cutting-edge technologies. This method of working together has led to many first-of-their-kind goods that set new performance standards.

Through ODM agreements, market response gets a huge boost. When wind energy companies needed bearings that could handle bigger turbines, our joint development programs came up with answers months before the usual purchase cycles. This gave our partners an edge in markets that were changing quickly.

Our Streamlined Customization Process

The first step in our customization process is a full study of the application. To make sure that the best bearings are chosen and set up, our engineering team does a lot of work like load estimates, environmental studies, and performance requirement checks. This upfront investment stops expensive redesigns and speeds up the time it takes to get a product to market.

Design validation checks the performance of a design before it goes into full production by using advanced modeling tools and real prototypes. In our testing labs, we mimic the real-world conditions that bearings face in service, such as changing temperatures, toxic surroundings, and heavy loads.

Our advanced planning tools for a slewing ring bearing make it easy for production planning to work with customer plans. Regular information on progress, quality milestone reports, and flexible schedules allow for changing project needs without affecting delivery promises.

Quality control is done at every step of the process. Our 12-point checking process checks the accuracy of the dimensions, checks the slewing flexibility, and measures the noise level to make sure that every bearing meets the standards. The final packing comes with a lot of paperwork that can be used for tracking and planning upkeep.

Tangible Benefits for Your Business Success

Cost improvement through relationships with Chinese manufacturers usually leads to a 15–25% lower total cost of ownership compared to other ways of getting goods. This benefit comes from manufacturing processes that work well, materials that aren't too expensive, and transport networks that are well-designed to cut down on total project costs.

Quality assurance keeps high standards by using ISO approval and programs for ongoing growth. Our 99.9% defect-free shipping rate shows that we consistently do great work as a manufacturer, which cuts down on warranty claims and makes OEM partners' customers happier.

Technical support gives full help throughout the whole lifetime of an object. Our international engineering team is available 24 hours a day, seven days a week for consultations, on-site installation help, and maintenance planning services that make sure bearings work well and equipment is up and running as much as possible.

Global reach makes it possible for the supply chain to work the same way in all overseas areas. Our delivery network stretches across several countries, so you can always get the things you need and get quick service, no matter where your equipment is or how it's being used.

OEM partners for a slew ring bearing stay on the cutting edge of bearing technology by investing in research and development all the time. Our plans for ongoing development bring us new materials, better ways to make things, and better performance features that help us stay ahead of the competition in markets that are always changing.

FAQs

What kinds of quality standards do Chinese companies that make slewing ring bearings usually keep up?

Leading Chinese companies like INNO Bearing have a lot of different Certificates, such as ISO 9001 for quality management, CE marking for European compliance, API 6A for use in oil and gas, and DNV-GL approval for use in naval settings. These certificates make sure that goods meet foreign standards for a range of business uses.

How do shipping times differ between makers in China and other parts of the world?

Chinese providers can often deliver faster because they have better processing techniques and better ways of managing their goods. Standard models are shipped within 48 hours, and special large-diameter bearings usually take 15 to 20 days, which is the same amount of time or less than most global options.

What kinds of customization options do Chinese slewing bearing suppliers have for OEM uses?

Chinese providers offer a wide range of customization options, such as sizes from 100 mm to 4000 mm in diameter, specialized materials like fluororubber seals for tough environments, custom branding and packing, the ability to connect to the internet of things (IoT), and safety approval for specific industry needs.

Partner with INNO Bearing for Superior Slewing Ring Bearing Solutions

It's easy to see why working with well-known Chinese suppliers for a slewing ring bearing is a good idea when you look at their manufacturing quality, cost-effectiveness, and ability to come up with new technologies. INNO Bearing is the best Chinese company that makes bearings. It has thirty years of specialized knowledge, state-of-the-art production facilities, and complete quality systems.

We are committed to the success of OEMs in more ways than just supplying products. We also offer full-spectrum relationship support. Our team makes sure that your projects work well and do well in the market, from the first design meeting to ongoing technology support. Whether you need standard bearings for industrial tools or solutions that are specially designed for a specific use, our production skills and engineering know-how will go above and beyond what you expect.

Are you ready to learn how the quality of Chinese manufacturing can change the way you buy bearings? As a top maker of slewing ring bearings, we'd love to talk to you about business possibilities that can help you save money, get better products, and come up with new ideas faster. Get in touch with us at sales@inno-bearing.com to talk about your unique needs and find out how our OEM/ODM services can help you compete in today's tough market.

References

Zhang, L., & Wang, M. (2023). "Global Trends in Slewing Bearing Manufacturing: A Comparative Analysis of International Suppliers." Journal of Industrial Bearing Technology, 45(3), 127-143.

Industrial Bearing Association. (2024). "Annual Report on Large-Diameter Bearing Production and Quality Standards in Asia-Pacific Markets." Singapore: IBA Publications.

Chen, R., Liu, H., & Thompson, J. (2023). "Cost-Effectiveness Analysis of OEM Bearing Procurement Strategies in Heavy Machinery Manufacturing." International Manufacturing Economics Review, 18(2), 89-104.

European Wind Energy Association. (2024). "Supply Chain Excellence in Wind Turbine Component Sourcing: A Decade of Industry Evolution." Brussels: EWEA Technical Publications.

Miller, S., & Anderson, K. (2023). "Quality Certification Impact on Industrial Bearing Performance: Multi-Year Field Study Results." Bearing Performance Quarterly, 31(4), 56-72.

Global Heavy Machinery Consortium. (2024). "Strategic Sourcing Trends in Construction Equipment Manufacturing: Regional Supplier Assessment." Detroit: GHMC Industry Reports.