The stakes could not be higher for engineering leaders and procurement teams who have to make important bearing choices for wind turbines, mining equipment, or heavy machinery. A tapered rolling bearing failure in a wind turbine's yaw system can cause tens of thousands of dollars in lost time, and early wear in a tunnel boring machine can stop building projects worth millions of dollars. Potential disasters can be turned into manageable operational concerns by understanding the right selection criteria, spotting failure trends early, and putting in place effective maintenance strategies. This complete guide talks about the tricky technical issues and real-world problems that quality assurance teams face when they have to choose these important spinning parts for tough industrial uses.

Understanding Tapered Rolling Bearings: Design, Function & Applications

Because their raceways are shaped like cones, tapered rolling bearings are a sophisticated engineering answer that can handle both radial and axial loads at the same time. Traditional ball bearings mostly deal with radial forces. These strong parts, on the other hand, spread combined loads over a bigger contact surface, which greatly increases their ability to hold loads and their ability to last for a long time.

What Is a Tapered Rolling Bearing?

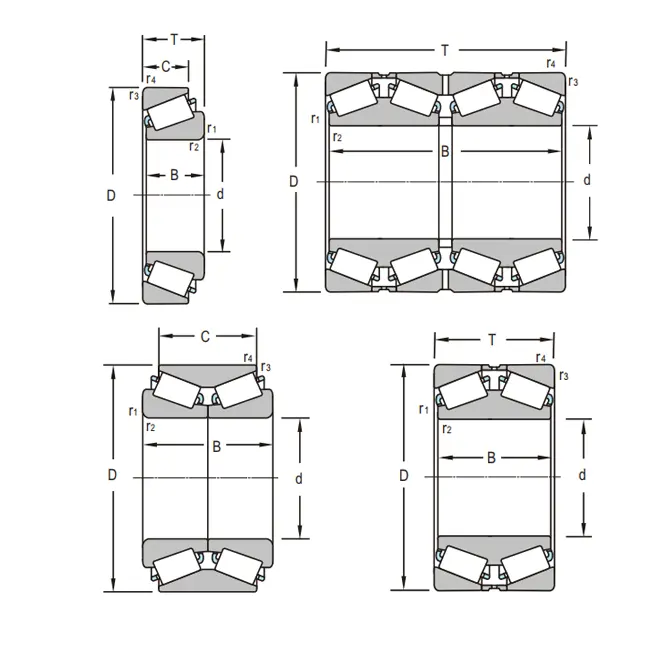

The basic structure has an inner ring with tapered raceways and carefully machined rollers. The outer rings can be separated (single-row configuration) or are fixed (double-row configuration). This geometric design makes it easier to distribute load, which is very important in heavy-duty situations. The inner diameter is 10 mm to 1000 mm, the outer diameter is 26 mm to 2000 mm, and the width is 8 mm to 300 mm. This makes it possible to meet a wide range of business needs.

Working Principle and Load Capacity

The cone shape makes it easy to control both radial forces (that are perpendicular to the shaft) and thrust loads (that are parallel to the shaft axis). When properly preloaded, these bearings get rid of internal clearances and keep the rotation smooth even in harsh circumstances. High-quality materials like GCr15, GCr15SiMn, and 20Cr2Ni4A steels last a very long time, and grades range from standard P0/P6 to ultra-precise P4/P5 meet the most exacting operational requirements.

Typical Applications Across Industries

For wind energy uses, main shaft assemblies and yaw mechanisms that work nonstop for decades need to be very resistant to wear and tear. Heavy machinery makers use these bearings in excavator swing motors and crane tracks, which have to work in tough conditions because of the combined load. In mining activities, large-diameter versions are used in ball mills and conveyor systems, where dirt and shock loads test the limits of how long bearings can last.

Selection Guide: Choosing the Right Tapered Rolling Bearing for Your Needs

To choose the right bearings, you need to carefully look at the operational factors, the environmental conditions, and the performance goals. When designing mission-critical software, engineering teams have to weigh technology needs against cost factors while also making sure that the software will work reliably for a long time.

Key Selection Criteria and Decision Metrics

To make the right choice, you need to do a load analysis that accurately measures both static and dynamic forces during the whole working cycle. Bearing design and lubrication needs are based on speed limits, which are usually given as limiting rotational speeds. Operating temperature ranges affect the choice of material, especially for uses above 200°C, where special metals are needed.

When it comes to uses that need thrust load capability, Tapered Roller Bearings are clearly better than Cylindrical roller bearings. Ball bearings work best when there is a lot of speed and not much load, but tapered configurations work better when rigidity and combined loads are the most important design factors.

Types and Variants of Tapered Rolling Bearings

For car wheel hubs and gearboxes, single-row designs are perfect because they are cost-effective and easy to install. Double-row designs make the structure more rigid and make mounting easier while lowering the overall complexity of the assembly. Four-point contact variants are used for specific needs where limited room calls for small Solutions.

There are different types of seals, from open designs that work well with oil baths to contact seals that keep out dirt and grime in tough conditions. Different types of cage materials, like stamped steel and brass, work differently. Brass is better at keeping lubrication in, while steel is better at withstanding shock loads.

Trusted Brands and Supplier Selection Tips

Well-known brands keep a lot of technical information and have a history of success in a wide range of tough uses. Specialized suppliers, on the other hand, often offer better value for custom uses that need non-standard shapes or specific material requirements.

Instead of just looking at the initial price, when evaluating a supplier, you should look at their quality certifications, technical help, and how reliable their deliveries are. Through collaborative engineering and lowering the total cost of ownership, OEM relationships often pay off in the long run.

Common Failures of Tapered Rolling Bearings and Troubleshooting Techniques

Understanding how things break down lets you plan proactive repair that stops big problems before they happen and gets the most out of replacement intervals. Pattern recognition from monitoring the state of bearings gives early warning signs that help decide when to step in and help.

Typical Failure Modes

When material flakes off of the raceway surfaces, this is called surface spalling. It usually means that the wear limit has been exceeded or that the lubrication is not good enough. Wear patterns show problems with misalignment, and rust damage shows that contaminants got in or the item wasn't stored properly. Discoloration and changes in size that make bearing clearances less reliable are signs of overheating.

Root Cause Analysis of Failures

About 40% of early bearing failures are caused by mistakes in the installation process. Bad mounting methods create stress concentrations that speed up the wear process. When particles, water, or chemicals get into a lubricant, they change its qualities and make it less effective. When something is loaded beyond its stated capacity, cracks start to spread, which eventually causes it to fail catastrophically.

Lubrication-related problems happen when the film thickness is too thin, the grease is dirty, or the wrong lubricant is used for the job. Vibration analysis shows when the roller parts are not lined up correctly, which causes the load to be spread out unevenly.

Case Studies Highlighting Problem Diagnosis and Resolution

A company that makes wind turbines had problems with the main bearings breaking down every 3 to 5 years instead of the expected 20 years. An investigation showed that the processes for adding grease were not done properly and that contamination was caused by worn seals. Adding automatic lubrication systems and better seal designs made bearings last longer than what was originally planned.

Due to coal dust contamination, mining equipment operators had to repair conveyor bearings all the time. When labyrinth seals with positive pressurization were switched to, the number of replacements dropped by 300% while working reliability went up.

Maintenance, Lubrication & Fixes to Maximize Bearing Lifespan

Systematic maintenance practices make bearings last a lot longer and save money on unexpected downtime costs. Using the right lubrication methods and condition tracking tools lets you plan preventative maintenance that figures out the best time to replace something.

Effective Maintenance Practices

To get an objective picture of the state of tapered roller bearings, they should be inspected regularly and include vibration analysis, temperature monitoring, and lubricant sampling. A visual inspection shows early signs of seal degradation, contamination entry, or problems that are getting worse and need instant attention.

Cleaning methods must find a balance between being thorough and keeping things from getting dirty. They must use the right solvents and keep the area clean during maintenance procedures. Keeping records of inspection results lets you look at patterns that help you figure out the best repair intervals.

Lubrication Methods and Best Practices

Because it is easy to use and doesn't get dirty, grease lubrication is good for most industrial uses. Oil ventilation systems are better at cooling and getting rid of contaminants, but they are harder to maintain. The amount of time between lubrications depends on the working conditions. Environments with a lot of dirt or high temperatures need more frequent attention.

Checking the compatibility of the lubricant stops chemical processes that hurt performance, and using the right amount stops both not enough protection and too much heat from being produced by too much lubrication.

Practical Fixes and Upgrades for Enhanced Durability

Upgrading seals is often a cheap way to make things better, and non-contact labyrinth designs cut down on friction while keeping safety levels high. Synthetic formulations have made lubricants better by extending the time between re-lubrication and increasing their temperature range.

When deciding whether to repair or replace something, you need to do an economic analysis that looks at the prices of bearings, installation, and downtime. Predictive maintenance technologies help make the best choices about when to make them.

Procurement Considerations: Pricing, Lead Time & Bulk Purchase Strategies

Strategic procurement planning strikes a balance between lowering costs and making sure the supply chain works as it should. This is especially important for mission-critical apps where a broken bearing can cause a lot of problems.

Understanding Price Influencers and Price Comparisons

Material costs change with the price of steel and alloy surcharges, and the need for accuracy has a big effect on manufacturing costs. Customization increases the cost of engineering, but it often gives better performance for a particular application than standard offerings.

Pricing systems are affected by volume, and negotiated rates are affected by the amount of commitment each year. Price changes happen because of changes in the market and how well suppliers are using their capacity. Skilled procurement teams use timing tactics to take advantage of these changes.

Managing Lead Times and Delivery Expectations

Standard bearing configurations usually have delivery times of 4 to 8 weeks, while custom designs need 12 to 16 weeks for planning and production. Strategic inventory placing and managing relationships with suppliers can help with emergency replacement situations.

Synchronizing production plans cuts down on the cost of keeping inventory on hand while still making sure that the machine is available during planned repair windows. Holding costs and stock-out risks in important applications should be balanced by buffer stock levels.

Optimizing Bulk Purchases and Negotiating with Distributors

There are often chances to get volume discounts when there are minimum order quantities, especially when needs are coordinated across multiple sites or projects. Long-term supply deals keep prices stable and make sure that allocation takes precedence when supply is limited.

Instead of just looking at prices, distributor evaluations take into account things like technical help, inventory positioning, and the quality of service after the sale.

Conclusion

The best performance from these important parts is guaranteed by the right selection, maintenance, and supplier relationship strategies. Understanding how failures happen and following proactive maintenance procedures will increase operations reliability and keep lifecycle costs low. As industrial applications continue to change to meet higher performance needs, tapered rolling bearings will stay essential parts that allow reliable operation in conditions that get harder.

FAQs

In terms of how they handle load, how are tapered rolling bearings different from ball bearings?

Due to their cylindrical raceway design, tapered roller bearings are very good at handling both radial and axial loads at the same time. Ball bearings, on the other hand, are mostly good at handling radial forces. Because tapered configurations have a larger contact area, they can hold more weight and are more rigid. This makes them important for heavy-duty uses like wind turbine main shafts and excavator swing drives, where different force vectors create complicated loading conditions.

What kind of maintenance plan should be used for heavy-duty tasks?

Heavy-duty applications usually need vibration analysis and temperature tracking every three months, as well as lubricant sampling and visual checks once a year. Depending on the working conditions, relubrication should be done every 3 to 12 months. In dirty environments, it should be done more often. Condition-based monitoring lets you make the best schedules, which stops failures and saves you money on repair costs that aren't necessary.

Can tapered rolling bearings be changed to fit the needs of a certain industry?

Modern production techniques allow for a lot of customization, such as non-standard sizes, special materials, changed geometries, and sealing solutions that are designed to work with a certain application. Custom designs are made to fit specific needs like limited space, harsh working conditions, and high performance standards that can't be met by standard catalog items.

INNO Bearing: Precision-Engineered Solutions for Critical Applications

Because they have been making specialized products for almost 30 years, Luoyang INNO Bearing Co., Ltd. can provide precision-engineered solutions that meet the most stringent industry needs. Designing, making, and providing expert support for a wide range of products, from wind energy systems to heavy mining equipment, is what we do best.

Our engineering teams can make bearings with diameters up to ±5000mm and accuracy grades up to P4/P5 levels, which is made possible by our many customization options. International standards are met with the help of advanced testing tools, and delivery schedules are kept that support important project deadlines.

Our way of making things is different because of the following benefits:

Our high-quality materials start with GCr15 and GCr15SiMn alloys, which are made of high-purity steel mixtures that go through vacuum degassing processes that make them 20% more resistant to wear than regular treatments. Thermal resilience makes it possible to work at temperatures up to 500°C by using special alloys and heat treatment methods that are best for harsh settings.

Dimensional accuracy is kept within ±0.001mm tolerances by precision manufacturing, even for non-standard shapes that need special engineering solutions. As part of quality assurance processes, spectrometry analysis, hardness verification (HRC 60–64), and full dimension inspection with coordinate measuring machines are all included.

With rapid prototyping, unique bearing designs can be made in just 15 days, which helps projects move faster while still meeting quality standards. Minimum order amounts that are flexible, ranging from 10 to 10,000 units or more, can be met for a wide range of buying needs, from developing prototypes to mass production.

The complex needs of modern industrial applications can be met by these manufacturing skills, which also meet the demands of engineering teams for reliability and consistent performance.

Global logistics networks make sure that standard configurations can be shipped within 48 hours and offer full technical help throughout the lifecycle of the product. Real-time load and temperature sensing made possible by IoT-enabled condition monitoring systems improve the ability to do predictive maintenance.

In situations where your applications need to work perfectly in harsh conditions, INNO Bearing has the technical know-how and manufacturing precision to make sure that they do. Our tapered rolling bearing solutions give important industrial uses the dependability and durability they need. Send us an email at sales@inno-bearing.com for full technical details and suggestions that are tailored to your unique needs.

References

Harris, T.A. and Kotzalas, M.N. "Advanced Concepts of Bearing Technology: Rolling Bearing Analysis, Fifth Edition." CRC Press, 2006.

Palmgren, A. "Ball and Roller Bearing Engineering, Third Edition." SKF Industries Inc., 1959.

American National Standards Institute. "Load Ratings and Fatigue Life for Ball Bearings." ANSI/ABMA Standard 9-1990.

International Organization for Standardization. "Rolling Bearings - Dynamic Load Ratings and Rating Life." ISO 281:2007.

Society of Tribologists and Lubrication Engineers. "Bearing Lubrication: A Practical Guide to Lubricant Selection." STLE Special Publication, 2018.

Mechanical Engineering Research Laboratory. "Failure Analysis and Prevention Methods for Industrial Rolling Bearings." Journal of Mechanical Engineering Science, 2019.