One of the biggest problems industrial engineers and purchasing managers in the heavy machinery, wind energy, and manufacturing sectors have is with the stability of turntable bearings. These rotating support systems, which are also called slewing rings, are put under a lot of different operating stresses that can lower their performance. This can cause unplanned downtime and expensive repairs. If engineering teams know what causes bearing instability, like material wear and tear, bad lubrication, and environmental contamination, they can come up with strategic Solutions that make equipment last longer and run more efficiently.

Understanding the Core Stability Challenges in Rotating Systems

Bearing stability includes a number of performance factors that have a direct effect on how reliable machinery is and how much it costs to run. The main problems with stability show up as too much vibration, strange spinning patterns, and early wear that can lead to failures across the whole system.

Most of the time, the biggest stability issues in large-diameter slewing rings are caused by uneven load distribution. When axial, radial, or moment loads go beyond what was planned or are spread out unevenly across the bearing surface, they put a lot of stress on the rolling elements, which speeds up the wear patterns. This effect is especially noticeable in wind turbine yaw systems, where changing wind loads cause dynamic stress conditions that make it hard for bearings to stay stable.

Material degradation is another important issue for stability, especially in hard working conditions. The 50Mn steel that is usually used to make turntable bearings has a great strength-to-weight ratio. However, if the inner and outer rings are exposed to temperature changes, wetness, and corrosive substances for a long time, they can lose their metal integrity. The GCr15 bearing steel rolling elements are made to last, but the surface can still wear down if they are used beyond the suggested load limits.

Uneven surfaces on the mounting cause stability problems that spread and affect the whole spinning system. When the flatness tolerance goes over the important ≤0.1mm/m limit, the load is spread out unevenly across the bearing contact surface. This causes vibration patterns that spread to other parts of the machinery that are linked.

Analyzing Different Bearing Configurations and Their Stability Performance

Under different operational situations, the stability characteristics of turntable bearings are greatly influenced by their structural form. When procurement teams understand these differences, they can choose the best options for each application.

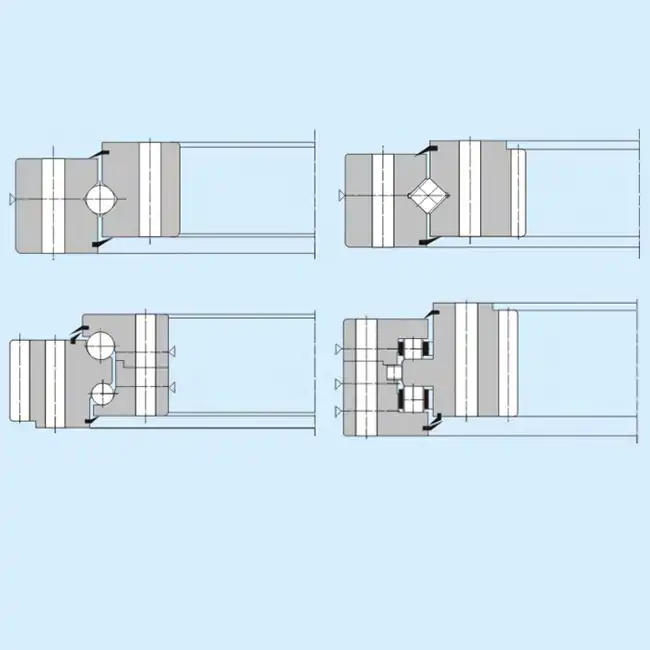

Single-row ball bearings work best in situations where the rotation needs to be smooth and the load needs to be low. The point contact between the balls and the raceways keeps friction to a minimum while still supporting the load of precision equipment like radar turntables and show display systems. But this arrangement is less stable when there are heavy vertical loads, because the contact stress can cause early fatigue.

Because they spread the load out better, double-row roller bearings are more stable for heavy-duty uses. When cylindrical rollers and raceways touch each other in a straight line, the loads are spread out over a bigger surface area. This reduces stress concentrations that could weaken the bearing's stability. When it comes to mining equipment, port cranes, and industrial machinery that needs to stay stable under heavy loads, these designs work really well.

Cross-roller bearing setups are the most stable choice for precise tasks that need high rigidity and low deflection. The alternating roller orientation handles mixed loads well while keeping the rotational accuracy very high. This configuration is very useful in aircraft applications and high-precision machine tool turntables that need precise control to stay stable.

The choice of material has a huge effect on how stable something is over time. The 42CrMo alloy choice is better at resisting fatigue than standard 50Mn steel, which is especially helpful for uses that have cyclical loading patterns. The optional GCr15SiMn rolling elements are more resistant to impacts and keep their stability even when they are loaded with shocks, which is common in heavy machinery uses.

Environmental Factors and Their Impact on Bearing Stability

The operating environment has a big impact on the stability of turntable bearings through a number of processes that change how well they are lubricated, their material properties, and the way they wear. Strategies for managing the environment become very important for keeping things stable.

Changes in temperature cause differences in the amount of expansion between the parts of a bearing, which could affect the fine fits that are needed for stable operation. Most configurations come with nitrile rubber seals that work well up to mild temperatures. Fluororubber alternatives, on the other hand, are more stable at higher temperatures that are common in metallurgical settings.

One of the most common threats to bearing safety is contamination. Exposure to dust, water, and chemicals can get into sealing systems and add gritty particles that speed up wear and make it harder for things to rotate smoothly, which is needed for stable operation. Modern turntable Slewing Bearings have dust-proof seals that protect them very well, but they still need to be inspected and serviced regularly to make sure they keep working well.

Through resonance effects, vibrations from nearby machines can make the function of a bearing less stable. When the natural frequencies of the bearing assembly match up with sound frequencies from the outside, amplification happens. This can speed up wear and make the bearing less stable. Using the right anchoring methods and vibration isolation tools can help lessen the effects of these outside factors.

Advanced Solutions and Technological Innovations for Enhanced Stability

Modern engineering solves problems with stability by using new design ideas and improved manufacturing methods that make things more reliable while lowering the need for maintenance.

Significant gains in bearing stability performance have been made by the following technological advances:

- Precision Grinding Technologies: New surface finishing methods make mounting surface flatness errors well below the important 0.1mm/m standard. This makes sure that loads are spread out evenly, which makes the whole system more stable.

- Better Seal Designs: Multistage sealing systems that use both labyrinth and contact seals work better at keeping out contaminants while keeping the low friction that is needed for stable spinning.

- Improved systems for lubrication: Integrated lubrication ports and distribution channels make sure that all contact areas get the same amount of lubricant. This keeps the machine from running dry, which is bad for stability.

- Load Distribution Analysis: Computer-aided engineering lets you precisely optimize the raceway geometry and the distance between the rolling elements to reduce stress concentrations and improve stability under a range of loading situations.

All of these technology advances work together to fix the main problems that make bearings unstable. They also offer measurable performance gains that make the investment in more advanced bearing solutions worth it.

When an application needs to be stable in a certain way, custom tech solutions can help. Bearings come in a wide range of sizes, with outer diameters ranging from 200mm to 5000mm. This means that they can be optimized for specific load patterns and working conditions that standard configurations can't handle.

Maintenance Strategies for Optimal Bearing Stability

Maintenance practices that are done before they break are very important for keeping spinning bearings stable over their entire useful life. When maintenance teams know when to do maintenance and when to do inspections, they can spot possible stability problems before they affect production.

Monitoring the smoothness of spinning on a regular basis can show early signs of stability issues. Maintenance workers with a lot of experience can pick up on small changes in how something rotates that mean it needs to be oiled, aligned, or a part replaced. Running noise from moving elements can help you figure out what's wrong. Higher noise levels usually mean there are more serious stability problems ahead.

Managing lubrication has a direct effect on how well stability works by changing the way friction works and how wear happens. Whether grease or oil is used for lubrication relies on the speed of operation, the type of load, and the environment. The right lubrication plans make sure that the film thickness stays the same, which keeps the rotation stable and stops metal-on-metal contact, which speeds up wear.

Checking the mounting surface is an important part of upkeep that has a direct effect on the stability of the bearing. By checking flatness tolerances and bolt torque specs on a regular basis, mounting irregularities that hurt load distribution and stability performance can be avoided.

Conclusion

Stability of turntable slewing bearings is an important part of keeping industrial operations running smoothly in a wide range of situations. When engineering teams understand how design parameters, environmental conditions, and maintenance practices all work together, they can improve stability performance while lowering running costs. When combined with proactive maintenance plans and skilled technical help, the cutting-edge solutions we have access to today offer complete solutions to stability problems. To manage bearing stability well, you need to work with experienced manufacturers who have the knowledge and skills to provide solutions that meet the strict needs of the industry world.

FAQs

What are the main signs that a turntable gear isn't stable?

The most common signs are higher rotational resistance, strange noises while operating, noticeable vibrations, odd wear patterns on mounting surfaces, and rising temperatures while operating. Monitoring these factors on a regular basis lets you find problems with stability quickly, before they cause the equipment to break down.

What effect does the size of the bearing have on how stable big machinery is?

Larger diameter bearings usually make things more stable by spreading the load over a larger area and resisting moments better. But as the size goes up, manufacturing accuracy becomes more important because it needs to be tighter to keep the level requirements needed for stable operation. The outer width ranges from 200mm to 5000mm, which makes it suitable for a wide range of uses while still meeting stability and performance standards.

How often should you do upkeep on a bearing to make sure it stays stable?

Maintenance times rely on how the machine is being used, but as a general rule, it should be visually checked every month, oiled every three months, and fully checked once a year, with measurements of flatness and wear analysis. Applications that are subject to a lot of stress or a harsh climate may need to be serviced more often to keep their stability.

Partner with INNO Bearing for Superior Turntable Bearing Solutions

To solve problems with stability, you need to work with manufacturers who have a lot of experience and know how to meet the complex engineering needs of current industrial applications. INNO Bearing offers turntable bearing solutions that are more stable and work better than expected thanks to its nearly 30 years of specialized experience and advanced manufacturing skills.

Our all-around method to improving stability starts with a thorough application analysis that looks at things like load patterns, environmental conditions, and performance needs. Because of this, we can suggest the best bearing configurations from our huge selection of single- and double-row designs, with customization choices that help with specific stability issues.

Our facility uses precise production methods to make sure that the quality is always the same, which has a direct effect on stability performance. Our 12-point inspection routine checks important factors like the flatness of the mounting surface, the accuracy of the rolling elements, and the integrity of the seals. These factors together determine the long-term stability and dependability of the system.

As a reliable company that makes turntable bearings, we offer full professional support that goes beyond just delivering the products. This includes help with installation, maintenance, and fixing problems. As part of our dedication to customer success, we offer quick response times and global logistics that keep downtime to a minimum when stability problems need immediate attention.

Get the reliability boost that comes from working with experts in stability engineering. Get in touch with us at sales@inno-bearing.com to talk about your unique stability needs and find out how our advanced turntable bearing solutions can help your business.

References

Harris, T.A. and Kotzalas, M.N. "Essential Concepts of Bearing Technology: Rolling Bearing Analysis." CRC Press, 2019.

Schaeffler Technologies AG. "Large Size Bearings: Technical Handbook for Slewing Bearings." Industrial Publishing, 2020.

American Bearing Manufacturers Association. "Load Ratings and Fatigue Life for Ball and Roller Bearings." ABMA Standards, 2018.

ISO 14728-1:2017. "Rolling bearings - Linear rolling bearings - Part 1: Dynamic load ratings and rating life." International Organization for Standardization.

Warda, B. and Chudzik, A. "Fatigue Life Prediction of Large-Size Slewing Bearings." Journal of Mechanical Engineering Research, Vol. 45, 2021.

Kania, L. "Modeling of Rollers in Calculation of Slewing Bearing with the Use of Finite Elements." Mechanism and Machine Theory, Vol. 81, 2019.