Different lubrication methods are used for Cylindrical roller bearings based on their operational needs, the environment, and the needs of the individual application. For general-purpose use, grease lubrication is the most common method. Oil lubrication systems are used for high-speed operations, and solid lubricants are used in extreme circumstances. Grease lubrication is easy to use and seals well, which makes it perfect for normal industrial machinery. Oil ventilation systems are better at getting rid of contaminants and transferring heat, which is especially helpful in high-load situations. Modern lubrication technologies use automatic dispensing systems and synthetic formulations to make service intervals longer while keeping bearing performance at its best in a wide range of industry settings.

Understanding Cylindrical Roller Bearings and Their Lubrication Needs

Precision-engineered roller bearing systems are used a lot in modern industrial uses to handle large radial loads while keeping operations running smoothly. These parts have circular rollers between the inner and outer rings, which are ribbed. This makes linear contact surfaces that spread loads evenly across the bearing assembly.

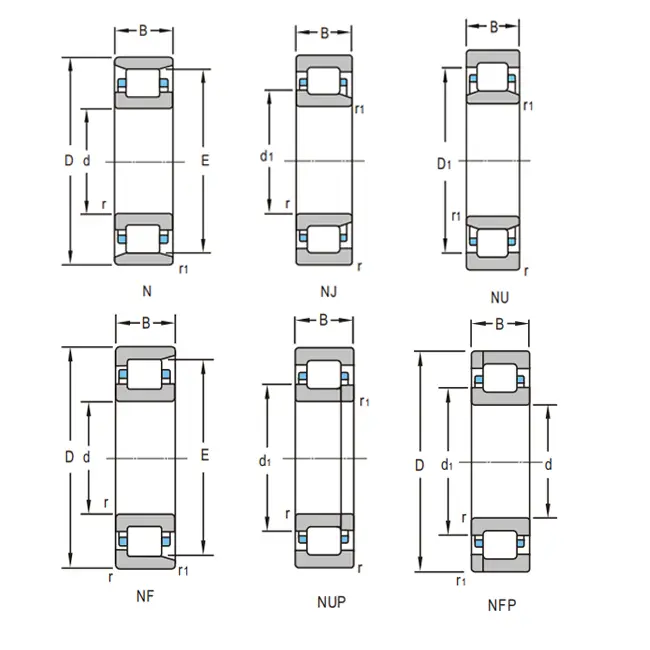

There are either single-row or double-row roller setups in the basic structure, and the cages are made of stamped steel or brass and can be open or sealed. The fact that the inner and outer rings can be taken apart makes repair and replacement easier. The current requirements for manufacturing cover sizes from 10 mm to 1000 mm in diameter, up to 2000 mm in diameter, and up to 300 mm in width.

The makeup of the material is very important for how well the bearing works and how well it works with lubricants. Rings and rollers in high-quality bearings are made of GCr15, GCr15SiMn, or 20Cr2Ni4A steel, and cages are made of cast steel or brass. For tough jobs, precision grades go up from the basic P0/P6 levels to the more advanced P5/P4 levels.

Lubrication needs are very different depending on things like rotational speed, load size, temperature, and the amount of contamination in the surroundings. When there isn't enough lubrication, metals touch each other, which causes surface stress, heat production, and faster wear patterns. On the other hand, good lubrication makes a protective film that splits surfaces that touch, lowers friction coefficients, and makes it easier for heat to move away from areas with a lot of stress.

Types of Lubrication Methods for Cylindrical Roller Bearings

To choose the right lubrication methods, you need to look at the operational conditions, performance standards, and maintenance capabilities. The following methods are standard in the business for improving the performance of cylindrical roller bearings in a range of situations.

Because it is easy to use and works well in moderate-duty situations, grease lubrication is the most common way. This method keeps things fixed even when the load changes. It does a great job of sealing. Base oils and thickening agents are mixed together in grease to make semi-solid lubricants that stick to bearing surfaces without the need for complicated distribution systems.

Some of the major benefits are less frequent maintenance, easier installation, and a natural resistance to contamination. Limitations show up in high-speed situations where spinning the grease creates too much heat and in places with very high or low temperatures where base oil separates. Depending on the load and the environment, most re-lubrication times are between 500 and 2000 hours of use.

The performance of oil lubrication systems is better for hard tasks that need better heat dissipation and contamination removal. Three main types of oil lubrication are used in industry:

Circulating oil systems move lubricant through bearing units, which keeps them cool and gets rid of debris. This method works great in high-speed situations where active thermal control is needed because of heat generation. Splash lubrication uses moving parts to spread oil throughout the bearing housing. It works well for medium-speed tasks with steady load patterns. When using oil bath methods, bearing parts are partially submerged in lubricant reservoirs. These methods are easy to use and work well for low to middle speed operations.

To meet specific needs, advanced lubrication technologies use solid lubricants, automatic dispensing systems, and nano-enhanced formulas. Solid lubricants, like molybdenum disulfide and graphite mixtures, work in places with very high or very low temperatures or vacuums where regular lubricants don't work. Automatic lubrication systems make sure that the right amount of lubricant is delivered while lowering the need for manual maintenance and the chance of mistakes.

Selecting the Right Lubrication Method: Key Considerations

To choose the best lubrication method, you need to carefully look at the operational factors, bearing specifications, and maintenance infrastructure. The type of load has a big effect on the choice of lubricant. For example, heavy horizontal loads need thick lubricant films to keep the metal from touching during times of high stress. For static loads up to 300kN, you need high-viscosity lubricants or increased pressure additives to keep the film thickness right.

How a lube works and how heat is made are affected by speed. Low-viscosity oils are usually needed for high-speed activities that go over 3000 rpm to keep lubricant films stable and reduce churning losses. When temperatures range from -30°C to +150°C, you need lubricants that have the right viscosity-temperature characteristics and thermal stability traits.

Environmental factors like dust, water, and chemical fumes can change the sealing needs and the compatibility of the lubricant. Dusty environments are better for sealed bearing designs that are lubricated with grease. Corrosive environments, on the other hand, need special lubricant formulations that are more resistant to rust.

Different bearing designs affect how grease is distributed and how long it stays in place. Single-row cylindrical roller bearings have simple ways to apply lubricant, but double-row designs might need different ways to make sure they get enough coverage. For full complement designs without cages, it's important to choose the right lubricant to keep the rollers from moving and the right distance apart.

Maintenance issues include how often the machine needs to be oiled, how easy it is to do the re-oiling, and figuring out the total cost of ownership. Automated lubrication systems save money on labor costs, but they need more money up front and upkeep know-how. Manual greasing has lower start-up costs, but it takes more work and there is a chance of making mistakes.

Best Practices for Lubricating Cylindrical Roller Bearings

Implementing good lubrication practices starts with following the right steps for preparation and continues with following set rules for checking. Activities that are done before lubrication set the stage for optimal bearing performance throughout their working lifetimes.

Failures caused by contamination can be avoided by following cleanliness standards when installing bearings and lubricating them. To get rid of preservatives, dirt, and handling contaminants, all bearing surfaces need to be cleaned thoroughly with the right solvents. Lubricant storage and handling rules keep the quality of the product high and stop it from absorbing water or getting contaminated with particles.

The right amount of lubrication stops both under- and over-lubrication, which both hurt the performance of bearings. When there isn't enough lubrication, the film thickness isn't thick enough. This causes border lubrication conditions and faster wear. Too much lubrication creates too much heat through churning, which can lead to seal failures or lubricant leaks.

The following rules will make sure that the best lubrication methods are used:

- Precise quantity control: Use manufacturer specs to figure out how much lubricant to use based on the bearing's size, speed, and load. The amount of grease should be between 30% and 50% of the available bearing space. The level of oil should be just right to keep the reservoir at the right depth without covering too much of the moving parts.

- Timing of the application: Set up lubrication schedules based on load cycles, working hours, or condition monitoring indicators. Lubrication may be needed every 500 to 1000 hours in high-load situations and every 2000 to 3000 hours in moderate-duty situations.

- Checking for quality: Check the state of the lubricant by sampling and analyzing it on a regular basis to find signs of contamination, oxidation, or additive wear-out. Before major failures happen, oil analysis tools find wear particles, the amount of water in the oil, and chemical breakdown.

These organized methods make sure that bearings always work well while reducing repair costs and unplanned downtime.

Monitoring plans include looking at vibrations, temperatures, and the state of the lubricant to figure out what maintenance needs to be done before they happen. Baseline measurements set the normal working conditions that can be used to compare with results from regular monitoring. Trending analysis finds patterns of slow degradation that show how well lubrication is working or how fast bearings are wearing out.

Conclusion

Choosing the right lubrication method for cylindrical roller bearings has a direct effect on how reliable the equipment is, how efficiently it works, and how much it costs to maintain in a wide range of industry settings. When you know how operational factors, bearing design features, and lubricant properties affect each other, you can make smart choices that improve performance while lowering the total cost of ownership. Fluid lubrication with grease is easy to use in most situations, oil systems work better in tough conditions, and new technologies allow for customized Solutions in the harshest settings. Systematic lubrication practices along with the right monitoring methods make sure that bearings work consistently and have a much longer service life.

FAQs

What kind of oil works best for cylindrical roller bearings that are used at high speeds?

Synthetic oils with low viscosity that are very stable at high temperatures and don't oxidize are often needed for high-speed uses. For speeds over 3000 rpm, circulating oil systems are the best way to cool things down and get rid of waste. Stay away from heavy greases that make too much churning heat.

How often should heavy-duty bearings be oiled again when they are under a lot of stress?

Heavy-load applications that are running at full capacity need to be re-oiled every 500 to 1000 hours, based on the weather. Use condition tracking to find the best intervals based on how the lubricant is actually breaking down instead of set schedules.

Can the same grease be used on different kinds of roller bearings in the same machine?

It is possible to get the best performance by matching the properties of the lubricant to the design of the bearing and the situations under which it is used. Before choosing a universal lubricant, you should think about things like the load distribution, speed ranges, and temperature exposure for each bearing position.

Advanced Cylindrical Roller Bearing Solutions from INNO Bearing

The engineers at Luoyang INNO Bearing Co., Ltd. have been working together for almost 30 years and are able to make fine bearings for the toughest industrial uses. Standard and special cylindrical roller bearings up to φ5000mm are part of our wide range of products. They are designed to work with heavy machinery, mining equipment, and power generation systems.

Making bearings out of high-purity GCr15 steel and vacuum degassing processes lets us make them with rotational load capacities up to 300kN static loads. Temperature resistance goes from -30°C to +150°C, and ceramic-coated rollers can be added for even harsher conditions. With precise tolerances, P4-grade specifications are met, which means there is little vibration and the service life is increased.

For more advanced customization choices, you can change the bore and outer diameter to within ±0.005mm, choose from different cage materials like stamped steel, brass, and polymer, and have sealing solutions made just for your environment. When used in mining, labyrinth seals keep dust out, and when used in marine settings, contact seals keep out water.

Protocols for quality assurance include three stages of inspection: checking the raw materials, testing with a coordinate measuring machine, and a full sound analysis. Our fast delivery services keep more than 1,000 standard bearings in stock and can send them out within 48 hours. Custom works up to ±3000mm are finished in 20 days.

As a reliable company that makes cylindrical roller bearings, we offer full technical help for the entire lifecycle of the product. Our engineering team helps with choosing the best way to lubricate, planning upkeep, and finding ways to make things run better. Rapid delivery and local technical help are made possible by regional warehouse networks in North America, Europe, and Asia.

Are you ready to improve the performance of your machines with precision-engineered bearing solutions? Get in touch with our technical experts to talk about your unique application needs and get personalized advice on how to lubricate and what bearings to use. Our skilled staff gives you detailed quotes and technical information to help you make choices about what to buy. You can email us at sales@inno-bearing.com.

References

Harris, Tedric A., and Michael N. Kotzalas. "Advanced Concepts of Bearing Technology: Rolling Bearing Analysis." CRC Press, 2006.

Hamrock, Bernard J., Steven R. Schmid, and Bo O. Jacobson. "Fundamentals of Fluid Film Lubrication." Marcel Dekker, 2004.

Eschmann, Paul, Ludwig Hasbargen, and Karl Weigand. "Ball and Roller Bearings: Theory, Design and Application." John Wiley & Sons, 1999.

Khonsari, Michael M., and E. Richard Booser. "Applied Tribology: Bearing Design and Lubrication." John Wiley & Sons, 2017.

Dowson, Duncan. "History of Tribology: Lubrication and Wear." Professional Engineering Publishing, 1998.

Budynas, Richard G., and Keith J. Nisbett. "Shigley's Mechanical Engineering Design: Bearing Selection and Application." McGraw-Hill Education, 2014.