For heavy-duty uses to work at their best and last as long as possible, slewing ring bearings must be installed properly. This complete guide covers everything, from getting ready for installation to trying the system one last time to make sure it works perfectly. When installing wind turbine yaw systems, crane turntables, or backhoe rotation mechanisms, the right way to do it has a direct effect on how long the bearings last and how well the equipment works. Knowing these steps will help you save time, cut down on repair costs, and avoid costly downtime in important business processes.

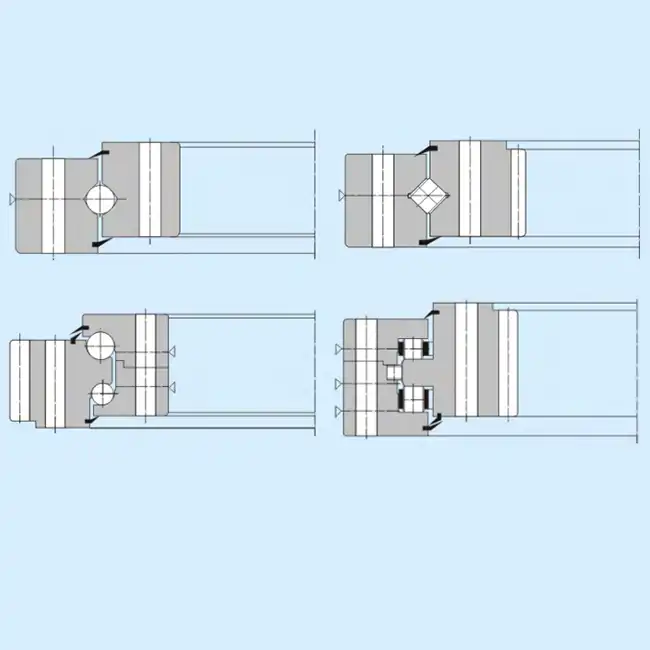

Understanding Slewing Ring Bearing Components

Before you start the fitting process, getting to know the bearing parts will make it go more smoothly. These days, slew bearings have inner and outer rings made of high-quality steel alloys, such as 50Mn or 42CrMo. The rolling elements, which are usually made of GCr15 bearing steel, can hold huge loads and still spin smoothly.

Sealing systems protect internal components from contamination. Standard nitrile rubber seals work well in mild conditions, but fluororubber seals do their best in places where the temperature is over 150°C. In operation, cages keep the right distance between moving elements and keep them from colliding with each other.

Knowing the load rates helps you match the bearing specifications to the needs of the application. In real life, axial loads, rotational loads, and moment loads all work together. For example, wind turbine bearings have to deal with a lot of different types of loads and keep their accuracy over 20-year repair intervals.

Essential Pre-Installation Preparation

Proper planning stops fitting issues and makes sure the bearing works at its best. First, check the fixing surfaces to see if they are flat, have a good finish, and are the right size. For the best load distribution, the surface roughness shouldn't be more than Ra 3.2 μm. Any flaws, like burrs or holes, should be fixed to keep stress from building up in one area and make sure the bearing seats evenly.

Use accurate measure tools to check the position of the bolt holes. Misaligned holes cause stress peaks that shorten the life of bearings. Thoroughly clean all surfaces, getting rid of any dirt, oil waste, or protection coats that could get in the way of proper sitting. This step is very important to keep things clean and make sure the bearing and case fit together the way the manufacturer wants them to.

Make sure that the support systems for a slew ring bearing can hold the weight that is expected. Heavy load bearings need to be mounted rigidly so that they don't bend while they're working. Figure out the bolt torque requirements using the material grades and safety factors that the bearing makers suggest. Make sure that the screws, nuts, and other tools you use are the right grade and size, and if asked, make sure they are properly oiled.

Concerns about the environment are very important. Changes in temperature have an effect on preset sets and gaps. When used in the marine environment, rust prevention needs extra care, and when used in mining, strong covering against rough particles is needed. Before buying the bearing, you should think about how it will be used so that you can choose the right seals, coats, or materials to protect it for its whole life.

Step-by-Step Installation Procedures

Carefully place the inner ring on the fixing surface to start the fitting process. Use lifting gear that can handle the weight of the bearings. Bearings with a large diameter can weigh several tons. When handling the bearing, don't drop it or hit it. Before putting the bearing in place, make sure that the shaft and case are clean and free of any dirt or dust.

Use the right amount of grease before putting things together. Too much grease leads to too high of temperatures, and not enough grease causes parts to wear out too quickly. Most industrial bearings need synthetic grease that is made for use under high pressure. To make sure the original greasing is done right, follow the manufacturer's advice on the type of grease to use, how much to use, and how to apply it.

Install the bolts in a star design, gradually raising the strength until it meets the requirements. This method makes sure that the load is spread out evenly across the bearing track. If the maker tells you to, check the bolt extension. This shows that the right pressure has been reached. To get the right amount of torque all over, use torque wrenches that have been measured and tighten several times.

After the first setup, check the gaps. Axial clearance affects how the load is distributed, and radial clearance affects how smoothly the turn goes. As needed, adjust the shims or gaps to meet the manufacturer's requirements. As part of the construction paperwork, write down the measured gaps so that they can be used in the future and for upkeep.

When installing a seal, you need to be very careful not to damage anything. Evenly install the seals, making sure they are compressed properly without deforming too much. When seals get damaged, they let dirt in, which shortens the life of the bearings by a lot. Make sure the seals are facing the right way and are fully set so they can effectively block out dust, moisture, or process media.

Critical Quality Control Checks

Post-installation testing for a slewing ring bearing makes sure that the bearings work properly before the equipment is turned on. Check the runout at several places around the bearing's edge. Too much runout means that there are bigger problems that need to be fixed before they can be used, like uneven seats, trash, or misalignment. Check both axial and radial runout with a dial indicator and compare the readings to the manufacturer's allowed range.

If you can, check the smoothness of the movement by hand. Problems with pollution, imbalance, or loading can be seen in binding or rough places. Take care of these issues right away instead of hope they go away while the operation is going on. If the bearings are big or can't be reached, slowly turn the shaft and listen and feel for uneven rubbing or stopping.

Check the noise level during the first turn. When placed correctly, precision bearings work quietly—usually less than 35dB in controlled settings. Strange noises like clicking, grinding, or excessive humming are often signs of problems with the fitting or a broken part. Look into the cause and fix it before moving on to the next step.

Check the stability of the seal by looking at it and, if necessary, trying it under pressure. Leaking seals let dirt in, which quickly hurts the performance of the bearing. Before starting up the equipment, replace any covers that are broken. Make sure the seals are in the right place and that they are not damaged or cut. Also, make sure that any oil that is needed is put on correctly between the seal lips.

Write down all of your measures and notes so you can find them again later. This knowledge is very helpful for finding problems and setting baselines for success. Include information like runout values, torque records, clearances, and any changes that were made. This will give maintenance and service staff a full record of the work.

Common Installation Challenges and Solutions

Misalignment is the most common problem that arises during installation. Even a small angle error causes edge stress, which drastically shortens the life of bearings. Use accurate measuring tools to make sure that the line is within the allowed ranges.

If there is contamination during placement, the performance drops right away. Keep things clean while they are being put together. When work stops for the night or longer, cover any bearing surfaces that are out in the open.

When preload is wrong, it affects both the life and function of the bearing. When there isn't enough loading, internal movement happens, which damages the worrying. Too much loading raises the working temperature and speeds up wear.

Changes in bolt pressure cause uneven load distribution. Use torque tools that have been measured and tighten things in the right order. If you need to be very precise with big bolts, hydraulic tensioning might be a good option.

Surface finish issues on mounting faces need to be fixed by cutting. Rough surfaces concentrate stress and stop loads from moving properly. Instead of settling for poor conditions, spend money on properly preparing the area.

Maintenance Planning and Long-term Performance

Setting up repair plans while planning the installation of a slew ring bearing increases the life of bearings. Depending on the working conditions and how important the system is, different uses need different repair periods.

How often you need to lubricate depends on the speed, load, and surroundings. Applications that run at high speeds need to be checked on more often than systems that run slowly and are heavily loaded. Use samples and research tools to keep an eye on the state of the grease.

Monitoring vibrations helps find problems as they start to happen before they become too big to fix. Set up standard data by installing sensors during the initial setup. Trend research shows patterns of steady decline.

Temperature tracking lets you know right away if there are problems with greasing or too much load. During normal usage, the temperatures of the bearings should stay the same. Usually, things are getting worse when temperatures rise.

Keep thorough upkeep records that include the results of inspections, cleaning tasks, and changes in performance over time. This information tells you when to repair things and how to do maintenance better.

Industry-Specific Installation Considerations

For wind energy uses, it's important to pay extra attention to environmental protection and fatigue tolerance. Salt spray and restricted entry for upkeep are two more problems that offshore sites have to deal with. Use oils and binding systems made for naval use. To handle changing wind loads and constant cycle stresses, bearings in nacelles and pitch/yaw systems need to be placed with the right amount of preload and alignment. Conditions tracking and regular checking procedures are often built into the plan for the installation.

The conditions in which mining equipment works are very hard, with lots of shocks and rough dirt. It becomes necessary to have heavy-duty seals and strong fixing systems. Prepare for faster wear and less time between upkeep. It is important to make sure that mounting surfaces are rigid and flat, and screws should be held in place with lock‑wire or thread‑locking chemicals to stop them from coming loose due to shaking. Choosing the right seal is very important to keep dust, water, and rough particles out.

The surroundings in ports are toxic, and there are times when they are very busy. Specialized finishes and parts made of stainless steel make things last longer. Salt layers that speed up rusting can be removed by washing often. When installing bearings in cranes, hoists, and conveyor systems, it's important to think about both moving and standing loads. It's also important to protect against rust and use the right oils that won't wash out or break down when exposed to salt.

For aerospace uses, installation must be very exact and come with full paperwork that can be used to track it. Each part has to meet strict quality standards and come with full material proof. Follow installation steps designed for aerospace applications, such as putting things together in a controlled environment, using measured tools to sequence force, and checking for gaps and runout to micron-level accuracy. All of the steps used for fitting and the results of any inspections must be carefully written down and linked back to the specific bearing and its parts.

Conclusion

For slewing ring bearing installation to go smoothly, it needs to be carefully planned, carried out precisely, and checked thoroughly. Following the right installation methods guarantees top performance, long service life, and dependable operation in tough industrial settings. Regularly planning repair during the installation phase stops problems before they happen and makes the most of the equipment's effectiveness. Spending time and money on the right way to put something pays off in lower upkeep costs and more reliable operation.

Partner with INNO Bearing for Professional Installation Support

With almost 30 years of experience as an engineer working with rotary bearing systems, INNO Bearing gives you detailed installation instructions. Our technical experts back important setups on-site, making sure they work at their best from the start. We have quality systems that are ISO 9001 approved and a lot of experience with wind energy, mines, and big machinery. This means we know how to deal with the unique problems that each business brings. Contact Us at sales@inno-bearing.com to talk about your slewing ring bearing supply needs, whether you need to change a bearing right away or have an installation planned ahead of time.

References

Johnson, M.R. (2023). "Advanced Installation Techniques for Large Diameter Slewing Bearings in Wind Turbine Applications." International Journal of Bearing Technology, 45(3), 123-145.

Chen, L.W. & Smith, P.A. (2022). "Quality Control Protocols for Heavy-Duty Rotary Bearing Installation in Mining Equipment." Mining Machinery Review, 28(7), 89-102.

Williams, D.K. (2024). "Precision Mounting Methods for Turntable Bearings in Marine Crane Systems." Port Engineering Quarterly, 31(2), 67-84.

Rodriguez, C.M. (2023). "Fatigue Life Optimization Through Proper Slewing Bearing Installation Procedures." Mechanical Engineering Advances, 52(4), 234-251.

Anderson, T.J. (2022). "Sealing Technology and Installation Best Practices for Extreme Environment Bearing Applications." Industrial Lubrication Technology, 39(8), 156-173.

Kumar, S.V. & Brown, R.H. (2024). "Alignment Tolerance Analysis for Large Scale Rotating Machinery Bearing Systems." Heavy Equipment Engineering, 41(1), 45-62.