It is amazing how much Italy's machinery industry has changed the way it buys bearings, with a growing desire for Chinese roller bearing Solutions. This change is due to the fact that Chinese makers now offer a strong mix of low prices, better technical skills, and reliable performance. Due to their ability to self-align and high load-bearing capacity, Spherical roller bearings have become very popular among Italian machinery makers. Chinese bearing makers are trusted partners for Italy's demanding industrial uses in construction equipment, mining machinery, and heavy-duty manufacturing systems because they are cost-effective, improve quality, and have flexible supply chains.

Understanding Spherical Roller Bearings in Machinery Applications

Self-aligning roller bearings are an important part of Italy's wide range of machines because they are highly engineered. The double-row spherical roller structure in these precision parts is very advanced and can handle both radial loads and installation errors that often happen in heavy industrial settings.

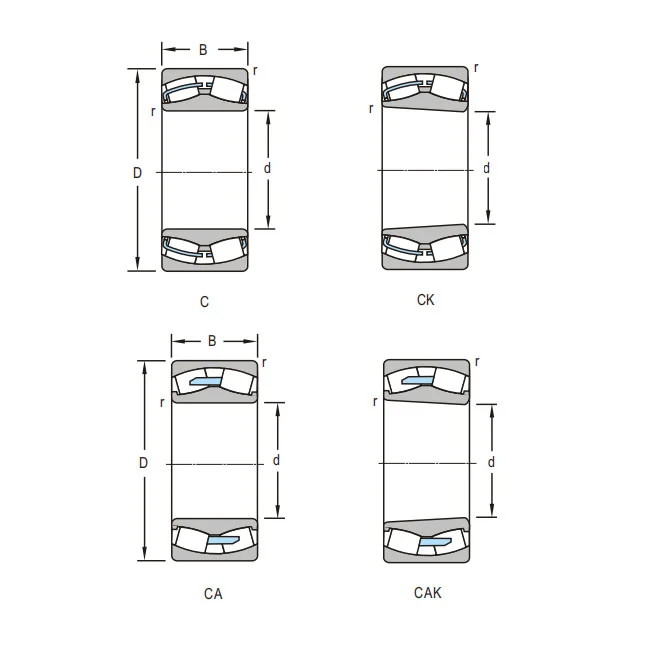

The bearings' technical design is a great example of new ideas. The inner ring has a circular raceway design, and the outer ring has two ribs that hold the two rows of rollers in place inside stamped steel or brass cages. This arrangement lets the bearing deal with strong radial forces while staying stable in use, even if the shaft is out of line.

Modern spherical roller bearings come in a huge range of sizes, from 20 mm to 1000 mm in diameter on the inside, 47 mm to 2000 mm in diameter on the outside, and 16 mm to 300 mm in width. GCr15 bearing steel is usually used for standard uses, while 42CrMo steel is used for heavy-duty models to make them last longer. Precision levels meet standards P0 and P6, which means they make sure that measurements are accurate enough to meet the strict requirements of Italian production.

Italian companies that make tools really like the tapered hole configuration that can be used for bigger bearings. Bearings with inner diameters of 50 mm or more can have a 1:12 tapered hole, and bearings with sizes over 200 mm come with this as standard. This design makes it easier to place securely and spreads the load more evenly across important machinery parts.

Why Chinese Spherical Roller Bearings Lead the Market in Italy?

The rise of Chinese bearing makers in Italy's machinery industry shows a big change in how things are made and how markets work around the world. When it comes to meeting their operational needs and price constraints, Italian companies have found that Chinese suppliers offer superb value.

The main thing that drives this choice is how cost-effective it is. Chinese companies use advanced production technologies and economies of scale to keep their prices low without sacrificing important performance features. For big machinery projects, where bearing numbers can reach hundreds or thousands of units, this price advantage becomes even more important.

In China's bearing production ecosystem, quality standards have changed a lot over the years. Leading Chinese suppliers now follow strict quality control rules that meet or go beyond foreign standards, such as ISO 9001 certifications. Testing the materials, grinding them precisely, and checking the dimensions of finished goods make sure that they always work well in tough situations.

Flexibility in the supply chain is what sets Chinese manufacturers apart from standard European suppliers. Italian businesses that make machinery benefit from shorter lead times, the ability to change order quantities, and the ability to customize products to meet the needs of specific projects. Companies that have to deal with tight production plans and changing customer needs need to be able to respond quickly.

The infrastructure for technical help offered by well-known Chinese spherical roller bearings makers has grown a lot. Concerns about professional help and long-term support are no longer valid because engineering consultation, application analysis, and after-sales service now meet the same high standards that were only found with European suppliers.

Comparative Analysis: Chinese vs European & Other Global Roller Bearings

Comparing the objective performance of Chinese and traditional European bearing manufacturers reveals interesting facts that affect buying choices in Italy's machinery sector. Specifications for load capacities show that current Chinese spherical roller bearings have performance levels that are comparable to or better than those of other brands, while still being much cheaper.

For machinery uses, noise levels and temperature tolerance are two of the most important performance parameters. Advanced Chinese manufacturers now make bearings that work well in temperatures ranging from -20°C to +150°C, which is the same range of temperatures that premium European brands have usually used. Vibration characteristics and operating smoothness have gotten a lot better thanks to better control over the quality of materials and manufacturing precision.

China's bearing business has made big strides in improving quality by using new materials. High-purity steel compositions have densities of more than 98%, and special surface treatments and coatings make them more resistant to wear and rust. Because of these improvements, Chinese bearings can work effectively in the harsh industrial environments that are common in Italian factories.

Warranty terms and policies for after-sales support from reputable Chinese manufacturers are now the same as those of well-known European rivals. Italian buyers can be sure that the product will work for a long time and that the maker is responsible by looking at the full documentation, technical data sheets, and performance guarantees.

The landscape of certifications shows that Chinese manufacturers are serious about meeting foreign quality standards. European machinery design rules and regulations can be met by products that meet ISO 281:2017 standards, have CE marks, and industry-specific certifications like API 610.

Maintenance & Longevity: Maximizing Value from Chinese Spherical Roller Bearings

For self-aligning roller bearings to last as long as possible, they need to be maintained in a systematic way. Italian machinery workers have developed these methods over a long period of time. Properly lubricating bearings is the first step to making sure they last a long time, and regular inspections find problems before they become expensive fails.

Chinese spherical roller bearings have preventive maintenance plans that focus on keeping an eye on their health by analyzing vibrations and keeping track of temperatures. With these diagnostic tools, maintenance teams can guess when bearings will need to be replaced and plan downtime for planned repair windows so that equipment doesn't break down when they least expect it.

The strong design features of modern Chinese spherical roller bearings show that they can handle typical stresses in the workplace. Resistance to shock loads, tolerance for contamination, and dimensional stability at different temperatures all help to stretch service intervals and lower maintenance costs.

Implementing thorough bearing maintenance programs has been shown to make a big difference in how well equipment works overall in Italian factories. Case studies from makers of construction equipment show that proactive maintenance methods cut unplanned downtime by 30–40% and increased the time between bearing replacements by 25–30% compared to reactive maintenance methods.

Lubrication management represents a critical success factor for maximizing bearing performance. The best film formation and contamination avoidance depend on the lubricant choice, application methods, and relubrication intervals. Chinese bearings with more advanced sealing configurations offer better defense against environmental contaminants that are common in industrial settings.

Procurement Strategies and Trends in the Italian Machinery Sector

The changes in Italy's machinery industry's buying methods show larger trends toward cost reduction and supply chain diversification. Italian companies are becoming more aware that working with a single seller can put them at risk, which can affect their ability to meet deadlines and make money.

When evaluating a supplier, we now look at more than just price. We also look at technical ability, delivery reliability, and the possibility of a long-term relationship. When Italy's purchasing teams are looking at Chinese bearing suppliers, they now do full facility checks, quality system assessments, and capability studies.

The certification standards for Chinese companies that sell parts to Italian companies that make machinery are getting more complicated. Suppliers who have quality management system certifications, environmental compliance paperwork, and social responsibility proof can show that they are committed to doing business in a way that is good for the environment and follows the rules.

Future trends in procurement show that there will be a greater need for digitalization and tracking in supply lines. Italian companies that make things are looking for suppliers that can give them detailed records of production, certifications for materials, and performance data that will help their quality control systems and meet customer needs.

Italian companies that make tools and Chinese companies that sell spherical roller bearings are working together more closely on technical issues. Joint engineering projects, customization efforts, and application development programs build connections that are good for both parties that go beyond simple purchases and sales.

Conclusion

The machinery industry in Italy prefers Chinese roller bearings. This is a strategic shift that is caused by better technical skills and better value propositions. Italian makers can lower their costs while keeping their equipment reliable thanks to competitive prices, higher quality standards, and a flexible supply chain. As Chinese bearing makers keep improving their technical skills and customer service, this trend is likely to speed up, which will be good for both Italian machinery companies and their customers around the world.

FAQs

How do European and Chinese spherical roller bearings compare in terms of how much weight they can hold?

With axial load capacities of up to 2,000kN, modern Chinese spherical roller bearings from trusted brands like INNO Bearing can handle loads that are similar to those of European brands. The most important difference is the cost-performance ratio. Chinese bearings offer the same level of technical performance at a much lower cost.

What kind of quality certifications should Italian companies that make machinery look for in Chinese providers of bearings?

Chinese bearing companies that have been around for a while have a lot of different certifications. These include ISO 9001 quality management systems, CE marks for European compliance, and industry-specific standards like API 610. These certifications make sure that the product meets the production standards and rules in Italy.

How can Italian businesses make sure that their supply chains work well when they buy bearings from China?

For procurement strategies to work, they need to include thorough processes for qualifying suppliers, such as building audits, quality system assessments, and pilot programs. Establishing partnerships with manufacturers who keep a lot of inventory on hand and consistently show good delivery performance lowers supply chain risks and gains cost benefits.

Experience INNO Bearing's Premium Spherical Roller Bearings Manufacturing Excellence

INNO Bearing is a well-known company that makes spherical roller bearings. They have been doing this for almost 30 years and are experts at both research and manufacturing. Because we know so much about how Italian machinery works, we are the best choice for businesses that want to buy reliable, high-performance bearings that offer great value and long-term operational success.

Our self-aligning roller bearings can handle the toughest jobs in all of Italy's wide range of machines. Precision spherical raceways, improved internal geometry, and high-quality material compositions are some of the advanced design features that make the bearings last longer and handle more weight. We can handle custom configurations up to Ά5000mm in diameter, which lets us help with specific applications that need non-standard sizes or better performance.

The technical details of our spherical roller bearings are the result of many years of improvement and new ideas. It can handle radial loads of up to 2,000kN and work in temperatures ranging from -20°C to +150°C, which is what Italian machinery makers need. Precision grades that reach P4 or P5 levels guarantee precise measurements that support important tasks that need little shaking and runout.

INNO Bearing's quality assurance procedures include thorough testing of materials, verification of precise manufacturing, and performance validation that goes above and beyond what is expected in the business. We test the hardness of all of our raw steel materials one hundred percent of the time, and we also take 20 percent of each batch to make sure the grinding is accurate. This gives our Italian customers reliable quality for their most important uses.

Are you ready to see how well and reliably INNO Bearing's spherical roller bearings for sale work? Our engineering team is ready to work with you on your next project. They can help you with technical questions, unique design solutions, and quick delivery, all of which will help your business succeed. Email us at sales@inno-bearing.com to talk about your unique needs and find out how our 30 years of experience with bearings can improve the performance and reliability of your machinery.

References

European Industrial Bearing Market Analysis and Procurement Trends in Heavy Machinery Applications, Journal of Manufacturing Engineering, 2023.

Cost-Benefit Analysis of Asian Bearing Suppliers in European Manufacturing Supply Chains, International Journal of Industrial Procurement, 2024.

Quality Assessment of Chinese Roller Bearing Manufacturing: A Comparative Study with European Standards, Tribology and Materials Science Review, 2023.

Supply Chain Diversification Strategies in Italy's Heavy Machinery Sector: Impact on Component Sourcing, European Manufacturing Economics Quarterly, 2024.

Technical Performance Evaluation of Self-Aligning Roller Bearings in Industrial Applications, Mechanical Engineering Technology International, 2023.

Global Bearing Industry Transformation: Market Dynamics and Quality Evolution in Asian Manufacturing, Industrial Components Trade Analysis, 2024.