Chinese vendors have become dependable partners for German machinery makers looking for precision-engineered Angular contact ball bearings, offering outstanding quality, competitive price, and cutting-edge manufacturing capabilities. These unique bearings manage combined axial and radial loads while upholding the exacting precision requirements required by German engineering prowess. Prominent Chinese producers, such as INNO Bearing, deliver bearings that satisfy DIN and ISO standards by fusing three decades of experience with cutting-edge production facilities. This guarantees a smooth integration with precision German equipment in a variety of industries, from heavy machinery to wind energy.

Understanding Angular Contact Ball Bearings for Precision Machinery

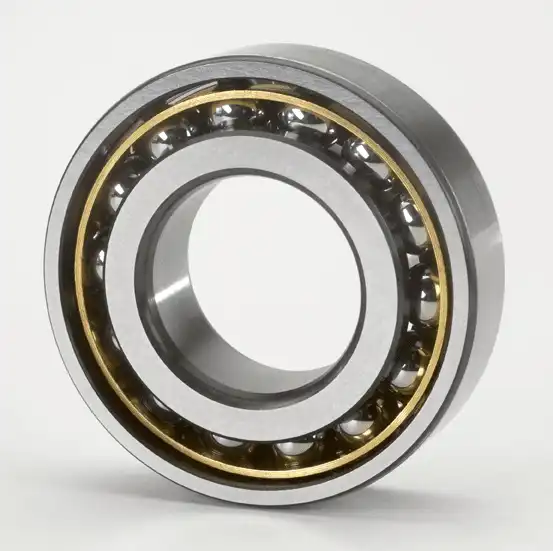

An advanced technical solution for complex load scenarios including both axial and radial forces is an angular contact ball bearing. Contact angles of 15°, 25°, or 40° are available in the special design; bigger angles offer more axial load-bearing capacity. Because of this feature, they are especially useful for German equipment applications that demand outstanding endurance and precise rotational control.

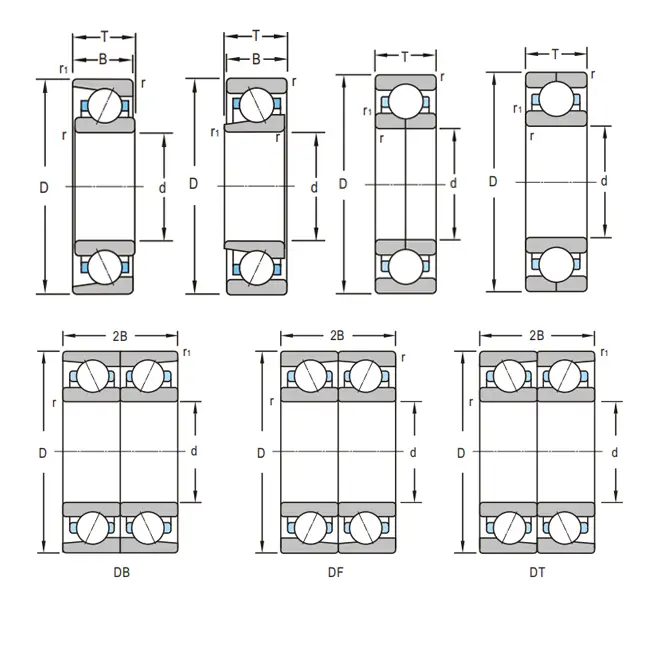

An inner ring, an outer ring with an angular contact raceway, single-row steel balls, and a cage system make up the basic structure. The shape maintains high operating speeds while enabling the best possible load distribution. These bearings can be arranged in pairs either face-to-face or back-to-back, giving engineers the freedom to meet the needs of particular applications.

The precision these bearings provide in machine tool spindles, turbochargers, and high-end motors is especially valued by German manufacturers. German engineering requirements are precisely aligned with the ability to operate under tough conditions while maintaining tight tolerances. In order to provide consistent performance in noise-sensitive situations, quality parameters include contact angle accuracy with deviations ≤ 1°, radial runout maintained at ≤ 0.005mm, and operational noise levels below 45dB.

Comparing Top Angular Contact Ball Bearing Types and Their Market Solutions

The needs of a given application and operational conditions play a major role in the choice of bearing configuration. Procurement teams can maximize performance and cost-effectiveness by making well-informed judgments when they are aware of these differences.

In high-speed applications where directional stresses are predominant, single-row angular contact ball bearings perform exceptionally well. Their excellent rigidity properties are combined with a streamlined design that reduces friction. Double-row systems, on the other hand, provide increased rigidity and load capacity, which makes them appropriate for applications needing higher structural stability or dealing with varied load directions.

In order to optimize performance, material selection is essential. While hybrid designs with ceramic components offer better speed capabilities and longer service life, standard GCr15 steel offers dependable performance for the majority of applications. The choice of cage material between aerospace aluminum alloy and traditional brass has an impact on environmental compatibility as well as operational speed limits.

Angular contact designs have special benefits over other bearing types. Despite their versatility, Deep groove ball bearings are unable to match the directional load capacity. Higher load ratings are offered by Tapered Roller Bearings, but speed possibilities are compromised. Self-aligning bearings reduce precision while making up for misalignment. Because of this, angular contact bearings are the best option for applications requiring both accuracy and load-bearing capacity.

Top Chinese Manufacturers and Suppliers of Angular Contact Ball Bearings for German Machinery

Over the past three decades, China's bearing manufacturing industry has seen a considerable transformation, and its top suppliers now offer notable cost benefits in addition to meeting international quality standards. To meet the needs of exacting German OEMs, these manufacturers have made significant investments in cutting-edge production technologies and quality control systems.

This progress is best demonstrated by INNO Bearing, which combines state-of-the-art production capabilities with nearly 30 years of industry experience. The business specializes in huge, non-standard bearings up to φ5000mm, meeting unusual needs that aren't met by ordinary catalog items. Strict quality control procedures and cutting-edge testing equipment are used in their facility to guarantee uniformity throughout manufacturing runs.

When choosing Chinese suppliers, quality certifications are an important evaluation criterion. Prominent manufacturers uphold industry-specific certifications, ISO 14001 environmental standards, and ISO 9001 quality management systems. For German buyers who want complete traceability and documentation, these qualifications offer assurance and show a dedication to global quality standards.

Chinese manufacturers differ greatly in their production capacities. Prominent vendors provide engineering assistance, quick prototyping, and customisation services on par with their European rivals. Their state-of-the-art facilities include automated assembly lines, CNC machining centers, and extensive testing labs that can validate performance across a variety of criteria, such as lifespan modeling, load testing, and vibration analysis.

Procurement and Logistics: Best Practices for Buying Angular Contact Ball Bearings in China

Strategic planning and careful due diligence are necessary for successful procurement from Chinese vendors in order to guarantee product quality and delivery dependability. Buyers may maximize value while navigating potential obstacles by having a thorough understanding of the procurement landscape.

Successful procurement is built on the foundation of supplier verification. Comprehensive paperwork, such as material Certificates, dimensions reports, and performance test results, is supplied by reliable manufacturers. Site audits can be carried out online utilizing video conferencing and third-party inspection services to confirm production capabilities and quality systems, despite the fact that they are difficult due to geographical distances.

Seasonal manufacturing capacity, customisation schedules, and minimum quantity needs are all factors to be taken into account when preparing an order. While many Chinese manufacturers want larger quantities for bespoke designs, they provide flexible MOQ rules for common products. Standard angular contact ball bearings usually have lead periods of 2-4 weeks, whereas specialty combinations requiring bespoke tooling have lead times of 8–12 weeks.

Several factors need to be taken into account while coordinating logistics, such as delivery options, customs paperwork, and packaging specifications. Sea freight offers cost advantages for large shipments, while air freight enables quick delivery for urgent needs. Product integrity during international transportation is ensured by appropriate packaging that uses shock protection and moisture barriers. To ensure a seamless customs clearance process, documentation must include commercial invoices, packing lists, and certificates of origin.

Maintenance, Troubleshooting, and Longevity Tips for Angular Contact Ball Bearings

Proactive monitoring techniques and methodical maintenance methods are necessary to maximize bearing service life. Predictable maintenance plans and little unscheduled downtime are especially valued by German machinery operators, therefore bearing dependability is crucial for operational effectiveness.

The foundation of bearing maintenance is lubrication management. Service life is directly impacted by choosing the right lubricant while taking operating temperatures, speeds, and environmental factors into account. Conventional greases are adequate for everyday uses, while synthetic lubricants frequently offer better performance in harsh environments. Frequent lubrication intervals ought to correspond with the level of environmental exposure and operating intensity.

By shielding precise surfaces from corrosive materials and abrasive particles, contamination prevention greatly increases bearing life. Contamination concerns are reduced by efficient sealing systems, routine inspection procedures, and environmental controls. To maintain bearing integrity prior to installation, storage practices must address temperature stability, humidity management, and appropriate handling approaches.

Early identification of emerging problems is made possible by performance monitoring that makes use of vibration analysis, temperature measurement, and sound monitoring. By tracking these metrics over time, one can identify trends of decline and schedule repair before a catastrophic breakdown happens. Predictive maintenance techniques that maximize equipment availability and maintenance expenses are preferred by the German industry, and this strategy fits that need.

Conclusion

With their sophisticated manufacturing skills, affordable prices, and extensive technical assistance, Chinese angular contact ball bearing manufacturers have made a name for themselves as trustworthy partners for German equipment applications of angular contact ball bearings. Choosing competent suppliers with validated quality systems, relevant certifications, and proven proficiency in precision bearing manufacturing is essential for success. With thirty years of industry experience and a dedication to technical quality, INNO Bearing is a prime example of these attributes, giving German manufacturers the accuracy, dependability, and performance their applications require.

FAQs

What impact do contact angles have on bearing performance in applications involving German machinery?

The ability to distribute load is directly impacted by contact angles. While greater angles (40°) improve axial load capacity, smaller angles (15°) maximize radial load management and high-speed performance. For balanced operation under combined loading conditions, German machinery normally needs contact angles of 25°.

What standards of quality can I anticipate from vendors of Chinese angular contact ball bearings?

Prominent Chinese producers offer precise grades ranging from P0 to P4, adhering to DIN 628 and ISO 15 requirements. European quality standards are met by quality measures such as noise levels below 45dB, radial runout ≤ 0.005mm, and contact angle precision within 1°.

Can specialist German equipment use custom angular contact ball bearings made by Chinese manufacturers?

Indeed, well-known vendors like INNO Bearing focus on creating unique Solutions with a diameter of up to φ5000mm. Throughout the design phase, engineering help is provided for material selection, precise grades, cage materials, and specific geometries.

INNO Bearing: Your Trusted Angular Contact Ball Bearings Manufacturer

INNO Bearing stands ready to support German machinery manufacturers with comprehensive angular contact ball bearings solutions designed to exceed performance expectations. Our wide range of products comprises basic configurations with inner diameters ranging from 15mm to 500mm as well as custom solutions up to φ5000mm for specialty applications with particular requirements.

Our nearly thirty years of experience in the bearing industry, along with ongoing investments in cutting-edge production technologies, are the foundation of our manufacturing excellence. We guarantee compatibility with the most exacting German machinery applications by maintaining precision grades ranging from traditional P0 to ultra-precise P4 levels. 100% dimensional inspection, performance testing, and thorough documentation that satisfies all traceability criteria are examples of quality assurance procedures.

INNO Bearing stands apart from conventional vendors thanks to its engineering support skills. In order to maximize bearing performance within certain equipment setups, our technical team offers application analysis, custom design services, and continuous technical advice. We use innovative modular production techniques to cut lead times for large bearings by 30% and deliver CAD drawings in 5-7 days.

Through well-established logistics partnerships and inventory management systems, global supply chain capabilities guarantee dependable delivery to German consumers. For urgent needs, we can ship within 48 hours and keep more than 1,000 standard models in stock. Get in touch with us at sales@inno-bearing.com to talk about your needs for angular contact ball bearings and find out how our experience can improve the functionality and dependability of your machines.

References

Harris, T.A. & Kotzalas, M.N. (2019). "Rolling Bearing Analysis: Advanced Concepts of Bearing Technology." CRC Press Engineering Handbook, 5th Edition.

German Engineering Federation (VDMA). (2021). "Precision Bearing Standards for Industrial Machinery Applications." VDMA Technical Publication 24568.

Zhou, L. & Wang, H. (2020). "Advanced Manufacturing Techniques in Chinese Bearing Production for International Markets." International Journal of Precision Engineering, Vol. 45, pp. 234-251.

European Bearing Manufacturers Association. (2022). "Quality Standards and Certification Requirements for Imported Industrial Bearings." EBMA Industry Report 2022-08.

Schmidt, K.H. & Mueller, F. (2021). "Angular Contact Ball Bearings in High-Speed Machinery: Design Principles and Performance Optimization." German Institute of Technology Quarterly, Vol. 78, No. 3.

International Organization for Standardization. (2020). "Rolling Bearings - Boundary Dimensions and Tolerances: Angular Contact Ball Bearings." ISO Standard 15:2020 Technical Specification.