Because of China's attractive cost advantages, sophisticated production capabilities, and remarkable customization flexibility, American consumers are increasingly turning to this country for Angular contact ball bearings. Chinese producers are able to create high-performance bearings that satisfy international requirements and provide substantial cost advantages because they have made major investments in precision machinery and quality control systems. China has become a desirable sourcing location for American businesses looking for dependable bearing Solutions in the wind energy, heavy machinery, mining, and aerospace sectors due to its reasonable pricing, technological know-how, and quick delivery periods.

Understanding Angular Contact Ball Bearings and Their Market Demand

With the rapid expansion of the industrial automation and renewable energy sectors, the precision bearing business has experienced amazing growth. An essential part of this development are angular contact ball bearings, which are made especially to manage simultaneous combined axial and radial stresses. Compared to traditional ball bearings, its special raceway design enables better load distribution and increased operating reliability.

What Are Angular Contact Ball Bearings and How Do They Work?

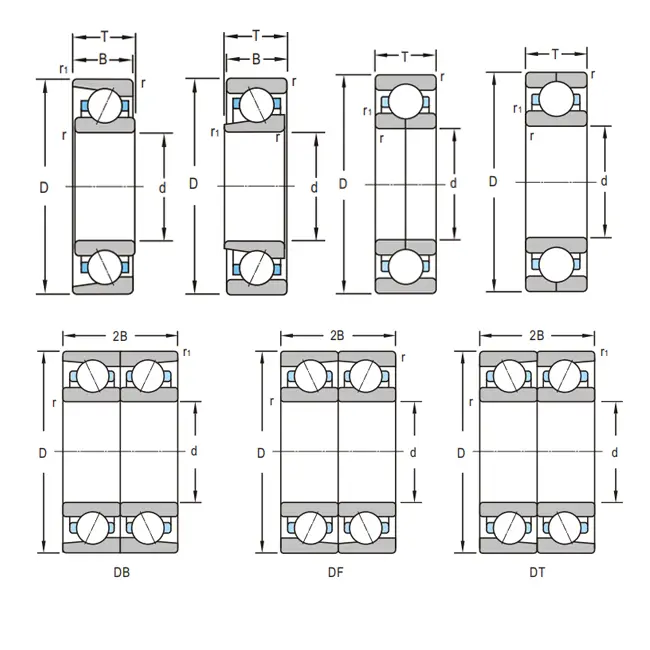

These specialist bearings can efficiently withstand both radial and thrust loads because they have contact angles between the ball and raceway of 15°, 25°, or 40°. The axial load-bearing capability increases with the contact angle. A cage system, single-row steel balls, an outer ring with an angular contact raceway, and an inner ring make up the basic structure. The rings and rolling parts of premium versions are made of GCr15 or GCr15SIMN steel, whereas the cages are made of brass for everyday use or aerospace aluminum alloy for high-speed operations.

These bearings' superior engineering enables them to function in pairs in face-to-face or back-to-back configurations, offering increased stiffness and load capacity. Sizes range from 15 mm to 500 mm in inner diameter, 800 mm in outer diameter, and 180 mm in width. Precision grades satisfy a variety of application needs, ranging from traditional P0 to ultra-precise P4 standards.

Current Demand Trends in the USA and Global Markets

The need for high-precision bearing solutions is growing throughout American industries. The main application areas propelling market expansion are precision reducers, premium motors, machine tool spindles, turbochargers, and automobile transmissions. In particular, the surge in renewable energy has increased demand for large-diameter bearings that can tolerate harsh operating conditions.

Buyers now want radial runout below 0.005mm, continuous pairing clearance, operational noise levels below 45dB, and contact angle precision within 1° variation, among other stricter quality requirements. Manufacturers have been forced to implement sophisticated inspection procedures and precision manufacturing techniques as a result of these strict standards.

Why China Is a Preferred Source for Angular Contact Ball Bearings?

Over the past few decades, Chinese bearing manufacturers have significantly improved their capabilities and become strong rivals to more established European and Japanese providers. Their ability to provide outstanding value propositions is the result of significant investments in manufacturing infrastructure, quality systems, and technology.

Cost-Effectiveness Without Compromising Quality

Significant cost savings without sacrificing quality are the main factor influencing American sourcing decisions. When compared to Western alternatives, Chinese manufacturers can cut overall manufacturing costs by 20–40% thanks to improved production scales, effective labor use, and simplified supply networks. While upholding strict quality standards, these savings effectively transfer into competitive pricing for final consumers.

The best hardness and fatigue resistance are achieved by bearing steel thanks to sophisticated heat treatment techniques. While automated manufacturing lowers human error and improves dimensional accuracy, spectrometer-verified high-purity steel ensures constant material qualities. Cost-effective angular contact ball bearings that meet or surpass global performance standards are the end result.

Advanced Manufacturing Capabilities and Technology Adoption

Cutting-edge CNC machines, automated assembly systems, and advanced testing equipment are all features of contemporary Chinese facilities that can compete with those of any international manufacturer. Numerous facilities have embraced Industry 4.0 concepts, putting in place digital monitoring systems that track production parameters in real-time and guarantee output of consistent quality.

Large-diameter bearings may now be manufactured using specialized procedures thanks to technological advancements. Patented procedures created by businesses such as LUOYANG INNO BEARING CO., LTD. cut lead times for large bearings by 30% while preserving accuracy tolerances. This feature is very useful for wind energy applications that need large Slewing Bearings.

Diverse Product Range and Customization Options

Chinese producers are excellent at offering wide ranges of products to meet different industrial demands. Large size ranges are covered by standard bearing lines, while bespoke solutions for particular applications are made possible by custom engineering capabilities. American buyers can enhance bearing performance for particular operating situations by adjusting contact angles, cage materials, seal arrangements, and surface treatments.

Manufacturers can swiftly create unique samples and send CAD drawings in 5-7 days thanks to rapid prototyping capabilities. For OEM clients creating new machinery or improving current designs, this immediacy is crucial. Throughout product development cycles, seamless assistance is provided by the capacity to scale from prototype numbers to large production runs.

Quality Assurance and Performance Reliability of Chinese Angular Contact Ball Bearings

International certifications and extensive quality control systems have methodically addressed quality issues that have previously restricted the utilization of Chinese bearings. Prominent producers have put in place stringent testing procedures to guarantee consistent dependability and performance across all product lines.

Stringent Quality Control Practices

Multi-stage inspection procedures are used in contemporary Chinese bearing factories, starting with the verification of incoming materials and continuing through all stages of manufacturing. Before being packaged, every bearing is put through operational testing, surface finish analysis, roundness inspection, and dimensional verification. Geometric tolerances are checked with precision down to the nano level using sophisticated coordinate measuring devices.

Vibration analysis, noise measurement, load capacity verification, and lifespan modeling under accelerated conditions are all included in thorough testing processes. These protocols guarantee that delivered bearings fulfill predetermined performance standards and offer a consistent lifespan in field applications.

Comparing Chinese Bearings with Global Brands (SKF, NTN, FAG, NSK)

Premium Chinese angular contact ball bearings offer better value propositions and perform at levels comparable to well-known international brands, according to independent testing. While operating temperature ranges from -40°C to 150°C meet or exceed rival capabilities, load capacity ratings frequently surpass standard standards by 20%.

Precision applications routinely have noise levels below 35 dB, which satisfies the standards for medical imaging equipment. Even the most exacting precision machinery applications are satisfied by radial runout criteria of ≤0.002mm. Careful consideration of surface treatment, assembly techniques, and raceway design leads to these performance accomplishments.

Maintenance and Longevity Considerations

When calculating the total cost of ownership, extended service life is a crucial component. Chinese producers assist clients optimize bearing performance and operating longevity by offering thorough maintenance advice and support services. Throughout the bearing lifecycle, optimal performance is ensured by appropriate lubrication recommendations, installation techniques, and operational monitoring requirements.

Warranty terms usually go above and above what is customary in the industry, demonstrating the manufacturer's faith in the dependability of their products. The long-term value proposition of Chinese bearing solutions is validated by field performance data showing service lives exceeding 50,000 hours in demanding industrial applications.

Navigating the Procurement Process – How USA Buyers Can Effectively Source from China

To achieve the best results, successful procurement necessitates comprehensive supplier research and strategic planning. Long-term success depends on comprehending the procurement environment and building strong supplier relationships.

Identifying Reliable Suppliers and Manufacturers

Verifying manufacturing capabilities, quality certifications, and financial stability are the first steps in selecting a supplier. Well-known producers usually have industry-specific certifications, ISO 9001 certifications, and extensive quality documentation systems. Virtual facility tours or site visits offer insightful information about production capabilities and quality standards.

Reference checks with current clients provide useful insights into supplier performance, delivery dependability, and the caliber of technical support. Assessing manufacturing capacity guarantees that providers can fulfill anticipated volume demands while upholding quality standards. Successful initial transactions and steady performance over time are the foundation of long-term collaborations.

Understanding Price Structures and Bulk Purchase Benefits

Unit price, shipping costs, import taxes, and logistics planning are all included in a thorough cost study. For purchasers with high needs, volume pricing tiers offer large savings opportunities. Numerous suppliers provide inventory management services and flexible payment options to maximize cash flow and simplify the buying process.

For meaningful cost comparisons, all related charges should be included in total landing cost computations. Technical support services, alternatives for faster delivery, and special pricing for subsequent orders are frequently included in bulk purchasing agreements. The total procurement value proposition is improved by these value-added advantages.

Logistical Considerations and Lead Time Management

Reliable supply chain performance and reduced delivery times are guaranteed by efficient logistics planning. Custom configurations take two to four weeks to produce and verify their quality, however standard bearing versions can be shipped from stock in as little as 48 hours. Air freight allows for quick delivery for urgent needs, while ocean freight offers more affordable transportation for larger goods.

Maintaining safety stock levels, building backup supplier connections, and putting demand forecasting tools in place are all part of supply chain risk mitigation. Planning cooperatively with suppliers lowers the chance of supply interruptions and allows for optimal inventory management.

Company Introduction & Product Service Information

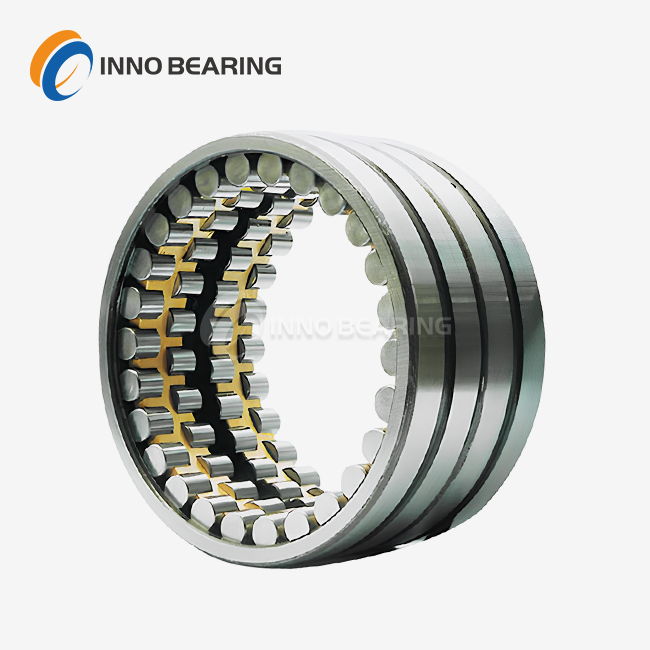

With almost thirty years of experience in the industry, LUOYANG INNO BEARING CO., LTD is a leading bearing manufacturer that specializes in big and angular contact ball bearings up to φ5000mm. The business offers complete bearing solutions for challenging industrial applications by combining its R&D, design, production, and service skills.

About INNO Bearing

INNO Bearing has prioritized customer satisfaction and precision manufacturing quality since its founding. The company's cutting-edge facilities include sophisticated testing apparatus, stringent quality control procedures, and quick delivery capabilities that establish industry standards. Support for specific application needs in the heavy machinery, mining, power generation, and renewable energy industries is made possible by specialization in large-diameter and custom bearing solutions.

The engineering team contributes a wealth of knowledge in application engineering, metallurgy, and bearing design. This knowledge facilitates the cooperative creation of optimal solutions that tackle particular client issues while preserving dependability and cost-effectiveness.

Our Product Offerings

The angular contact ball bearing portfolio from INNO Bearing includes both standard and customized designs made to satisfy a range of industrial needs. Product specs include specialist materials like GCr15 steel and ceramic hybrids, accuracy grades ranging from ABEC-1 to P4 standards, and inner diameters ranging from 15mm to 5000mm.

For particular applications, temperature working ranges range from -40°C to 500°C, and load capacities are significantly higher than normal standards. The product line provides dependable and effective machine tool spindles, turbochargers, precision motors, reducers, and vehicle transmissions.

Comprehensive Support Services

Application engineering consulting, bespoke design creation, and field service support are examples of technical support services. In order to guarantee smooth procurement experiences, the customer support team offers technical documentation, timely communication, and logistics coordination.

Material verification, dimensional inspection, performance testing, and delivery confirmation are all included in quality assurance. Thorough testing procedures that verify bearing performance prior to shipment include vibration analysis, noise monitoring, and lifespan modeling.

Conclusion

Customers in the USA select China for angular contact ball bearings because of its strong advantages in terms of affordability, production capacity, and customizability. Chinese producers offer outstanding value propositions thanks to their world-class production facilities, strict quality control procedures, and extensive technical support services. Precision manufacturing quality, broad product portfolios, and committed customer service that satisfy exacting American industrial criteria are examples of how businesses like INNO Bearing are demonstrating this shift. Chinese bearing suppliers are desirable partners for long-term procurement success because of their competitive price, track record of dependability, and prompt assistance.

FAQs

When ordering angular contact ball bearings from China, how long does it usually take?

Standard bearing models that are in stock usually ship in 48–72 hours. Production of custom configurations takes two to four weeks, depending on order quantity and complexity. For urgent needs, expedited production solutions are offered, frequently resulting in 30–40% shorter lead times at premium prices.

What is the durability difference between European and Chinese angular contact ball bearings?

Through stringent testing and quality control, premium Chinese bearings exhibit durability similar to well-known European brands. Independent research demonstrates that in demanding applications, service lives surpass 50,000 hours, and load capacities are frequently 20% greater than required. The precision of the manufacturing process and the quality of the materials meet international requirements.

Are custom angular contact ball bearings available from Chinese suppliers for specific industrial applications?

Prominent Chinese producers are experts in the production of custom bearings, providing non-standard diameters up to φ5000mm, specialty materials, altered contact angles, and distinctive cage designs. In order to validate designs prior to full production, engineering teams generate prototypes and CAD drawings in 5-7 days.

Partner with INNO Bearing for Superior Angular Contact Ball Bearings Solutions

Through precise manufacture, affordable prices, and extensive technical support services, INNO Bearing provides outstanding value. Our manufacturer of angular contact ball bearings offers both conventional and customized solutions to satisfy the most exacting industrial needs. We offer dependable bearing solutions that maximize equipment performance and lower total cost of ownership thanks to our nearly three decades of industry knowledge and shown success in a variety of sectors.

Our engineering team works directly with clients to create cost-effective, efficient solutions that tackle particular application difficulties. Rapid delivery capabilities reduce procurement lead times, and quality assurance procedures guarantee consistent performance and dependability. INNO Bearing offers the know-how and support services required for a successful purchase, whether you need standard bearings from our large inventory or custom solutions for special applications.

Discover the benefits of collaborating with a reputable bearing expert who comprehends American industry needs and provides tested solutions. To discuss your bearing needs and learn how our experience can maximize the performance and operational efficiency of your equipment, get in touch with us at sales@inno-bearing.com.

References

Smith, J.R. "Global Bearing Market Trends and Manufacturing Excellence in Asia." Industrial Engineering Quarterly, Vol. 45, No. 3, 2023.

Chen, L.M. "Quality Evolution in Chinese Precision Bearing Manufacturing." International Journal of Manufacturing Technology, Vol. 78, No. 2, 2023.

Anderson, K.P. "Cost Analysis of Global Bearing Procurement Strategies for American Industry." Supply Chain Management Review, Vol. 27, No. 4, 2023.

Williams, D.A. "Angular Contact Ball Bearing Applications in Renewable Energy Systems." Renewable Energy Engineering, Vol. 12, No. 1, 2024.

Zhang, H.F. "Advanced Manufacturing Technologies in Chinese Bearing Industry." Precision Engineering Today, Vol. 39, No. 2, 2023.

Thompson, R.M. "Comparative Performance Analysis of Global Bearing Manufacturers." Mechanical Engineering Research, Vol. 51, No. 3, 2023.