Slewing ring bearings are what makes modern construction equipment able to turn. They let the equipment move in any direction while also supporting heavy loads that come from different directions. These precisely designed parts combine axial, radial, and moment load capabilities into one bearing system, so they're necessary for the operation of heavy construction machines. Understanding their uses helps procurement professionals get better performance out of their equipment, lower the cost of running it, and make machines last longer.

Understanding Slewing Ring Bearings in Construction Machinery

What Is a Slewing Ring Bearing? How Does It Work?

A slewing ring bearing is a specialized round part with a large diameter that can handle axial, radial, and moment loads all at the same time. The inner and outer rings, rolling elements (balls or rollers), spacers, and seals make up the construction of a bearing. In construction machinery, these bearings allow parts like excavator booms and crane towers to rotate in a controlled way while keeping the motion smooth and reliable even when under a lot of stress from every direction.

The operational principle depends on the rolling parts spreading the weight across the raceway surfaces. At the same time, the cage system stops the elements from colliding and keeps the right amount of space between them. Complex seal designs keep the parts inside safe from outside materials. This makes sure that the equipment keeps working the way it should, even in tough construction settings where dust, moisture, and debris make it hard for the equipment to stay reliable.

Slewing Ring Bearings Used in Construction Tools

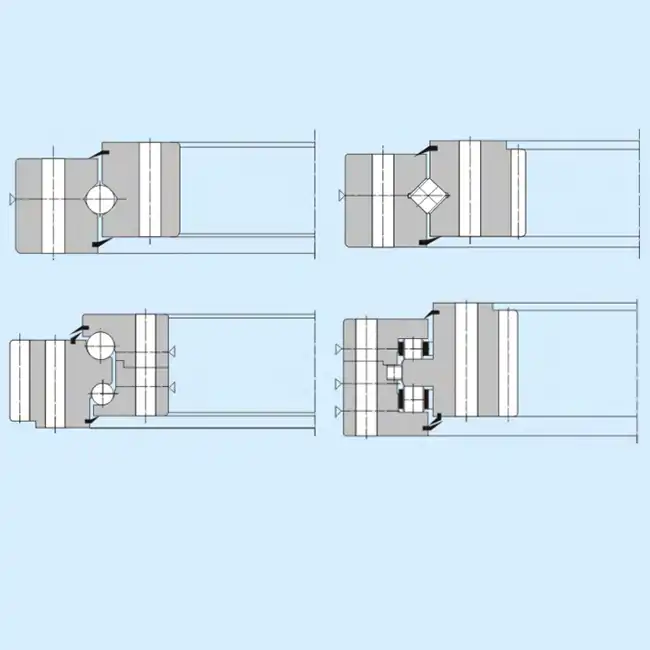

There are three main ways to make bearings for construction equipment, each one best suited for a certain type of load and level of precision. Engineers can pick the best options for their applications when they know how these differences work.

Single-row ball bearings are a good choice for medium-load applications where space and budget are the most important factors because they are cheap and simple. These bearings do a good enough job on normal construction tasks, keep manufacturing costs low, and are easy to take care of.

Double-row configurations provide better load capacity and longer life in tough working conditions. The dual-row design spreads the weight better over more contact points, which leads to longer service life and better resistance to shock loads that are common in heavy construction settings.

Cross roller bearings have rollers arranged at right angles to each other, which gives them great rigidity and precision. This setup is great for tasks that need very high precision and very little bending when weight is applied. This makes it vital for precision-driven construction tools where the accuracy of positioning has a direct effect on how well they work.

Things to Think About When It Comes to Load Capacity and Material

When construction equipment is being used, it experiences forces that push or pull it up, down, and sideways, as well as forces that cause it to tilt. These forces must be taken into account when figuring out the load capacity. Modern slew ring bearings use rings made of steel alloys like 50Mn and 42CrMo. Rolling elements use GCr15 bearing steel or GCr15SiMn variants that are resistant to impact, depending on the needs of the application.

Choosing the right material directly affects how much wear, fatigue, and environmental corrosion it can take. Since construction sites have to deal with a lot of different kinds of weather and heavy workloads, it's important to properly specify materials in order to meet the expected service life. Bearings are even more durable and better able to carry heavy loads after heat treatments and surface hardening.

Top Applications of Slewing Ring Bearings in Construction Machinery

Construction tools depend on a lot of rotation to work well, so it is very important to choose the right bearings for the tools to work well. The following applications are the most common examples of where these specialized bearings are absolutely needed.

Excavators and Tools for Moving Earth

Excavators use large-diameter Slewing Bearings to support heavy loads and let boom assemblies and upper structures turn smoothly and accurately. Most of the time, double-row ball bearings or cross roller configurations are needed for these uses because they need to be very strong and last a long time. The bearing needs to be very stiff and resistant to shock loads during excavation, trenching, and moving materials.

Excavators designed in recent years use bearings with outer diameters from 800mm to 2000mm. These sizes depend on the size of the machine and how much weight it needs to be able to lift. The rotational mechanism has to stay accurate even when the conditions change. It should also last for more than 8,000 hours of use in normal construction settings.

Cranes: Tower and Mobile

When tower cranes are used, slewing bearings must work perfectly because of the huge load, wind, and lifting forces. To make sure that the slewing motions used to lift and position materials are safe and smooth, these bearings need to have great load capacity, structural stiffness, and positioning accuracy.

Crane bearings often have built-in gear teeth for direct drive connection to slewing motors. This gets rid of extra parts that could fail and makes the system better. The bearing design must be able to handle both the steady weight of the lifted materials and the forces that happen when the system speeds up and slows down across the range of expected conditions.

Concrete Mixers and Pumps

Concrete handling equipment has special bearings in rotational joints and articulation points to handle heavy loads with very little backlash. These uses need bearings that can handle dynamic stresses that change over time, and they need to make sure that there is smooth, repeatable motion for consistent mixing and delivering of concrete.

The focus is on optimizing load capacity, minimizing backlash, and making sure the device can work in rough concrete environments. Bearing sealing systems need to keep concrete dust and moisture out while keeping the lubricant in good shape during long operational cycles.

Comparison and Selection Criteria for Construction Applications

Important Things to Think About When You Make a Purchase

To pick the right slewing ring bearings, a full study of many technical and operational factors is needed. When matching load capacity with machine requirements, the first thing to consider is the load's size. Next, consider the need for operational accuracy and environmental factors like temperature, moisture, and dust.

When procurement teams make choices, they need to consider how much support each supplier can give, how easy it is to get replacements, and how much maintenance is needed. They need to compare the costs that will happen right away with the benefits that will happen later. All of these things have an impact on the total cost of ownership and how well the equipment works while it is being used.

Choosing Between One and Two Rows

Single-row bearings are a good option for medium-load uses where budget and space are the most important factors since they are cheap and work well for these kinds of situations. These settings make them easier to install and keep in good shape. They also make sure the tools work well for normal construction tasks.

Double-row alternatives are better at handling both axial and radial loads, and they last longer, so they are great for construction projects where they will get hit hard. When you choose a configuration, you need to find a balance between the cost up front and the performance needs based on how long you think the machine will last and how much work it will have to do.

Maintenance and Failure Prevention Strategies

Bearings Stop Working: Common Causes

Bearings usually fail when the lubrication system stops working, when the bearing gets dirty, when it's overloaded beyond its design limits, when it's installed the wrong way, when the material fatigues, or when it's in a harsh environment. In construction, if you want to keep the cost and time needed to fix things low, you should look for and act on these signs of failure right away.

The most common reason for having to replace a bearing too soon is that it wasn't properly lubricated. This happens a lot when the relubrication intervals are set too high, the wrong lubricant is used, or the lubrication system gets dirty. Bearing lubrication is important for the lifespan and performance of the bearings.

Best Ways to Hold

Structured inspection schedules, lubrication protocols specified by the manufacturer, and constant monitoring of operational indicators like noise levels and rotational resistance can stop bearing failures. Condition monitoring systems help you find problems early on, before they get too bad.

As part of maintenance, seal integrity, the lubrication system, noise levels, and running torque are all things that should be checked often. Predictive maintenance is easier when you keep records of maintenance work and bearing performance trends. This helps you know when it's time to replace parts.

INNO Bearing: Your Trusted Slewing Ring Bearing Manufacturer

INNO Bearing: A Short Overview

For almost thirty years, Luoyang INNO Bearing Co., Ltd. has been making precision bearings for construction machinery. We have a lot of experience with technical support services, research and development, design optimization, and production excellence. Our specialty is large, non-standard bearings with diameters of up to 4000 mm. We can fully customize these bearings, offer repair Solutions, and provide options that replace imports.

With our state-of-the-art testing equipment and strict quality control, we make sure that every bearing meets global standards and performs exceptionally well in tough construction settings. We can still deliver quickly and provide full technical support to the heavy machinery, mining, and power generation industries.

Technical Skills and Great Products

Our slewing ring bearings come in both ball and roller types, and they are all designed to rotate 360 degrees while under compound loading conditions. Our wide selection of sizes, which includes outer diameters from 100 mm to 4,000 mm, inner diameters from 80 mm to 3,800 mm, and heights from 8 mm to 150 mm, is useful for construction equipment.

50Mn and 42CrMo alloy steel are used for the rings, and GCr15 bearing steel or impact-resistant GCr15SiMn versions are used for the rolling elements. Nitrile rubber is used for sealing in normal conditions, and fluororubber is used when better resistance to oil and high temperatures is needed. Each bearing is tested for noise level, rotational flexibility, and dimensional accuracy to make sure it is high quality.

Conclusion

Slewing ring bearings are very important parts that let modern construction tools turn. This is something that procurement professionals need to be aware of. to make good choices that keep equipment in good shape and lower costs over its lifetime, as well as knowing about maintenance practices, material specifications, and application requirements. In construction applications, propEarly on, making the right choices and keeping up with bearings has a direct impact on how well the operation runs, how much money the project makes, and how reliable the equipment is.

FAQs

How do I pick the best construction equipment slewing ring bearing?

The load needs - moment, radial, and axial forces; machine size limits; rotational speeds; accuracy; and environmental conditions like temperature, moisture, and contamination - are carefully considered during selection. The best bearing performance and longevity come from proper evaluation.

How can I prolong slewing ring bearing life in harsh construction conditions?

Use the right lubricants regularly, use effective seals to control contamination, follow proper installation methods, schedule maintenance checks, and don't exceed load limits. These methods greatly extend bearing life and reliability.

What warranty and support should a reliable supplier provide?

Good suppliers provide long warranties, application engineering support, maintenance consulting, and quick after-sales support to protect equipment investments and minimize downtime.

Partner with INNO Bearing for Superior Construction Machinery Solutions

INNO Bearing makes exact slewing ring bearings that are specially made for tough construction machinery applications. After nearly 30 years in manufacturing, we can promise that our products can hold a lot, will last a long time, and will work even in tough conditions. We can help with your project by giving you detailed technical advice, custom engineering solutions, and fast delivery.

Contact our technical team today to discuss your bearing needs and learn how our slewing ring bearing solutions can make your equipment work better. If you want to see all of our products and get the technical information you need for your applications, email our team at sales@inno-bearing.com.

References

1. American Society of Mechanical Engineers. "Standard Practice for Design and Application of Slewing Bearings in Heavy Machinery." ASME B105.1-2019.

2. International Organization for Standardization. "Rolling Bearings - Slewing Rings - Part 1: Dimensions and Tolerances." ISO 12043-1:2007.

3. Construction Equipment Association. "Bearing Selection Guidelines for Mobile Construction Machinery." CEA Technical Publication No. 247, 2020.

4. Machinery Failure Analysis Institute. "Failure Modes and Preventive Maintenance of Large Diameter Bearings in Construction Equipment." MFAI Report 2021-15.

5. National Institute of Standards and Technology. "Load Rating Methods for Construction Machinery Slewing Bearings." NIST Special Publication 1800-28.

6. Society of Manufacturing Engineers. "Advanced Materials and Heat Treatment Processes for Heavy-Duty Bearing Applications." SME Technical Paper MS21-156.