In 2026, slew drive bearings will be a vevery important technology that will change industrial automation in many areas. These carefully designed parts can rotate and drive something, so they are needed for everanything from wind turbines to AGV robots. As companies want more reliability and efficiency, procurement managers and engineering teams looking for the best Solutions need to know which parts of the economy are driving this market.

Understanding Slew Drive Bearings and Their Core Advantages

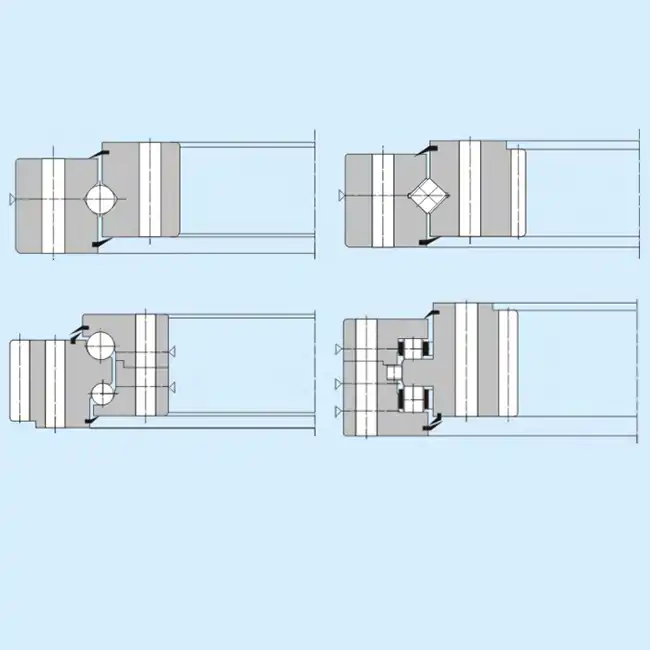

Today's slew drive bearings combine small gear sets with single-row steel ball bearings to make a single system that allows smooth rotation even under heavy loads. These parts have bearing housings with mounting holes in the right places so that gears can connect directly with the inner or outer rings of the slewing bearing mechanism.

Building and Technical Details

Modern units usually work with outer rings that are 100 to 500 mm across and 50 to 150 mm tall. The output rotational speeds range from 0.5 to 50 revolutions per minute. This makes them useful for fine applications that need to control movement. The building uses high-quality materials, like 50Mn and 42CrMo for the inner and outer rings. Rolling elements are made of GCr15 or GCr15SiMn steel to better resist impacts.

Advanced Sealing and Safeguarding the Environment

In industry, environmental resilience is still very important. Nitrile rubber seals are used in modern designs for normal conditions, but fluororubber seals can be used instead in situations that require high temperature resistance and oil resistance. This two-seal method keeps the device working in a wide range of conditions while also keeping the lubricant in place and protecting against contamination.

Top 5 Industries Driving Demand for Slew Drive Bearings in 2026

Rotational bearing technology is being used more and more in many different industries, with five very important ones driving this growth. Each area has its own needs that lead to new ways of designing and making bearings.

Wind Energy and Long Lasting Power Sources

Ultra-large bearings that can handle extreme fatigue loads and keep the right positioning are needed in the renewable energy sector. Companies that make wind turbines need parts that are made of high-quality metals and can be tracked all the way through the supply chain. When these applications fail, the results are often disastrous. They usually include main shaft support, yaw systems, and pitch control mechanisms.

With strict adherence to international standards, quality assurance teams and engineering directors put service life of more than 20 years first. The tough environment, which includes exposure to saltwater and changes in temperature, means that better corrosion-resistant coatings and specialized lubrication systems are needed.

Construction Tools and Heavy Machinery

Excavators, cranes, and tunnel boring machines all depend on construction equipment makers to provide them with big round parts that can spin. These applications require both an amazing ability to bear weight and precision machining tolerances that guarantee smooth operation even when conditions are very stressful.

When choosing slew drive bearing solutions, mechanical engineers and OEM project leaders look at both how customizable the solutions are and how stable the delivery is. The ability to make old machines compatible with new parts without slowing down production opens up a lot of market opportunities for bearing designs that can be used in different ways.

Using Robots and Automation

The robotics industry is growing, and it uses small, very accurate parts for AGV robots, rotating worktables, and smart PTZ systems. These uses need their gear meshing to be very accurate and running noise to be low so that automated systems can know exactly where they are and work smoothly.

Medical equipment makers especially value the features that make noise levels low and control precise, because they help with delicate surgeries and make patients more comfortable. Adding smart sensors and IoT connectivity makes modern bearing solutions even more useful in healthcare settings.

Mining and Metallurgy

Some of the most difficult places for machines are in mining operations. Heavy-duty bearings need to keep working reliably even when they are under a lot of weight, in rough conditions, and when the temperature changes. Mills, stackers, reclaimers, and rotary kilns are examples of applications where production delays cost a lot of money when parts fail.

Maintenance engineers put easy servicing and part accessibility at the top of the list of things to consider when choosing bearing solutions. Being able to do routine maintenance without taking apart a lot of different machines makes operations run more smoothly and saves money.

Engineering for boats and oil rigs

Marine applications need to be able to deal with harsh saltwater conditions by having great structural reliability and resistance to corrosion. Ship loaders, offshore cranes, and drilling platforms depend on specialized bearing solutions that meet tough certification standards and always work the way they're supposed to.

When marine engineers and project procurement teams choose parts for offshore applications, they look at how well they resist corrosion and how much weight they can hold. Many marine installations are far away from other places, so reliability and long service intervals are very important when choosing them.

How to Select the Best Slew Drive Bearing for Your Industry Needs

Choosing the right slew drive bearing solutions requires a lot of thought about how they will be used and the conditions they will be in. The process of making a decision looks at load requirements, accuracy needs, and the possibility of having to maintain the system in the future.

Operational Needs and Load Capacity

To choose the right bearing, you need to know about axial and radial load requirements. When shock loads or changing patterns of loading are involved, better structural design and material specifications are needed. Bearing design parameters and expected service life are directly affected by the operational speed range and duty cycle.

Environmental Factors and Factors That Are Specific to the Application

The performance and lifespan of bearings are greatly affected by the environment. The levels of pollution and exposure to moisture and extreme temperatures affect the sealing requirements and material specifications. When corrosive environments are present, special coatings and advanced seal designs are needed to make sure that the parts continue to work properly over time.

Maintenance and Longevity Tips for Slew Drive Bearings in Industrial Use

Effective maintenance directly affects how well bearings work and how long they last. Creating a detailed inspection and preventive maintenance schedule will help your equipment stay up and running and lower the risk of unexpected failures.

Rules for Checking and Keeping an Eye on

Regular checks of the slewing clearance, gear meshing accuracy, and running noise can help you spot problems before they happen. Vibration analysis and thermal monitoring are useful for spotting problems before they affect the reliability of the operation. These proactive methods are much cheaper to maintain than reactive repair methods.

Lubrication and protecting the environment

Proper bearing lubrication management keeps them working well and extends their life. The environmental conditions affect how often and what kind of lubricant is used. Bad conditions mean that service intervals have to be done more often. Long-term reliability also depends on preventing contamination with good sealing systems.

Future Outlook: Industry Trends Influencing Slew Drive Bearing Usage in 2026 and Beyond

The bearing industry is always changing because of new findings in materials science and new ways of making things. Smart bearings with sensors in them let you plan maintenance ahead of time. This keeps the equipment in good shape and prevents unexpected downtime.

New findings in manufacturing and material science

In a lot of different situations, using more advanced metallurgy and coating technologies helps with load capacity and corrosion resistance. Precision manufacturing makes parts that last longer with less friction by create tighter tolerances and smoother surfaces. These changes are great for apps that need to be very accurate and dependable.

Environmental Factors and Long-Term Effects

People are coming up with new ways to make things and design bearings that are better for the environment and use less energy as they become more aware of environmental issues. The industry is still able to protect the environment and meet performance standards with recycling programs and getting materials in an environmentally friendly way. These trends follow the rules about how businesses must act and are in line with the industry's big goals for long-term sustainability.

Conclusion

Slew drive bearings are used more and more in the renewable energy, construction, automation, mining, and marine industries because they are versatile and work very well. Understanding the needs of your industry helps you make smart choices about who to hire or work with that will make your business run more efficiently and save money in the long run. As technology moves forward in areas like materials science and smart sensor integration, these very important parts will be used more and more in industrial automation and precision machinery.

FAQs

When choosing a slew drive bearing for heavy equipment, what load capacity should I look at?

It depends on your application what the load capacity requirements are, but most industrial units can handle axial loads from 300 kN to 15,000 kN and radial loads from 200 kN to 8,000 kN. When specifying requirements, think about both steady and changing load conditions, including shock loads and operating cycles that can change.

How do environmental factors impact the choice of bearings and the schedule for their upkeep?

The performance of bearings is greatly affected by the environment. Corrosive places need special coatings and seals. Also, very hot or cold temperatures affect the materials used and the way things are lubricated. In harsh conditions, inspections and preventive maintenance are usually needed more often.

Can slew drive bearings be made to fit special uses and retrofit projects?

Yes. Top companies, such as INNO Bearing, offer a range of custom options, from changes to standard designs to fully engineered units. Special materials, coatings, sealing systems, and changes to the size of the product are some of the ways that it can be customized to meet the needs of different applications.

INNO Bearing: Your Trusted Slew Drive Bearing Manufacturer

INNO Bearing is a top slew drive bearing supplier that provides custom solutions for a wide range of industrial uses. Our full range includes standard and custom-designed units with diameters from 100 mm to 5000 mm. They are made with 50Mn and 42CrMo steel and other advanced materials using special heating methods.

We have almost 30 years of experience in the industry, and we offer full technical support from the first meeting to installation and upkeep. Our quality assurance program has strict tests that make sure every part meets high performance standards. Our engineers come up with reliable, cheap ways to solve bearing problems, whether you need standard units for AGV robots or custom solutions for mining equipment.

Find out how INNO Bearing's advanced slew drive bearing technology can help your machines run better. For technical help and good prices on custom bearing solutions that fit your needs, email us at sales@inno-bearing.com.

References

Industrial Bearing Technology Handbook, 4th Edition. Society of Tribologists and Lubrication Engineers, 2024.

Renewable Energy Equipment Design Standards. International Wind Energy Association Technical Committee, 2024.

Heavy Machinery Bearing Applications and Performance Analysis. American Society of Mechanical Engineers, 2023.

Marine Engineering Component Specifications for Offshore Applications. Society of Naval Architects and Marine Engineers, 2024.

Automation Systems Integration and Precision Component Selection. International Federation of Robotics, 2024.

Mining Equipment Reliability and Maintenance Best Practices. Society for Mining, Metallurgy & Exploration, 2023.