Conical roller bearings are very important parts of many industrial uses where machinery has to deal with big radial and axial loads at the same time. These tapered roller assemblies work great in places that need to be able to handle heavy loads, where they need to last a long time, and where they need to work with perfect precision. Bearings are important for wind turbine manufacturers' main shaft assemblies, and heavy machinery makers use them in excavators and mining tools. Understanding the many useful applications and technical benefits of conical roller bearing technology gives procurement managers, engineering directors, and quality assurance teams the ability to make strategic sourcing choices that improve the dependability of their equipment and the efficiency of their operations.

Strong bearing Solutions that can handle very tough conditions are important for today's work in renewable energy, heavy machinery, mining, port engineering, aerospace, and other industries. These roller bearings have a special tapered shape that spreads out weight better than normal ball bearings or cylindrical rollers. This makes them very important for rotating machines used in critical missions where failure isn't an option.

Understanding Conical Roller Bearings: Design and Functionality

Outstanding Structural Engineering

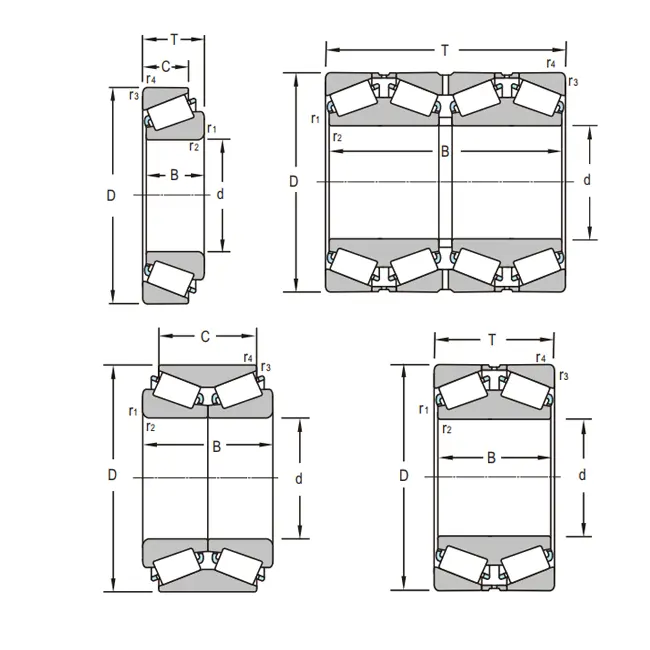

Conical roller bearings have a complex design with tapered raceways on the rings' inner and outer sides. The rollers are placed at exact angles to make sure the bearings can handle loads better. The inner ring has a tapered raceway that works with the outer rings, which can be set up as single-row separable or double-row fixed. This method of engineering makes it possible to handle both radial and axial forces at the same time while keeping the system stable when the load changes.

The roller and cage assembly is made of high-quality materials. The roller's components are made of GCr15 and GCr15SiMn steel, and the cage is made of stamped steel or brass, depending on what it needs to be used for. These bearings come in open and sealed types. They can be used in a wide range of environments, from normal industrial settings to harsh mining and offshore conditions.

How Load Distribution Works

The tapered shape allows the best contact patterns between rollers and raceways. This spreads the weight over a larger area than the point contact shape used in ball bearings. This basic benefit leads to higher load ratings, longer service life, and better resistance to wear even when heavy-duty conditions are in play. The optimization of the cone angle makes sure that the stress is evenly spread. This stops early failure modes that are common in other kinds of bearings when they are under combined loading situations.

Size Range and Standards of Exactness

The dimensions that can be made in manufacturing range from 10 mm to 1000 mm for inner diameter, 26 mm to 2000 mm for outer diameter, and 8 mm to 300 mm for width. The level of precision can be as low as the P0 or P6 grade, which is used for general industrial purposes, or as high as the P5 or P4 grade, which is used for ultra-precision applications where very high accuracy and low runout tolerance are required.

Typical Applications of Conical Roller Bearings in Industry

Wind and Power That Lasts a Long Time

Wind turbine OEMs use large-diameter Tapered Roller Bearings in main shafts, yaw systems, and pitch control mechanisms because they need to be able to last. For these uses, full traceability throughout production and strict control of metallurgical quality are needed. To get the most energy out of each generator, the bearings must keep their position while dealing with constant changes in direction, temperature, and wind.

Offshore wind farms need more solutions to resist saltwater corrosion and make maintenance easier. To get the job done, engineering teams want bearings that don't rust and seal better. These are needed for marine service periods longer than 20 years.

Heavy Tools Used in Building

Heavy-duty conical roller bearings are needed for the swing mechanisms of excavators, the rotation systems of cranes, and the drives of tunnel boring machines. These are very important for companies that make construction equipment. These uses require high load-bearing capacity to stand up to the extreme forces of digging, lifting, and moving materials. The bearings need to stay correct even though they are used all the time with heavy loads in dirty conditions.

The bearings in marine equipment resist corrosion and meet global maritime rules. Ship loaders and port cranes are some of them. OEMs can change how bearings are set up for different loads and working conditions. This helps them compete around the world.

Mining and metals

Ball mills, stackers, reclaimers, and rotary kilns all need to deal with tough conditions and heavy weights. For this reason, mining operators use heavy-duty conical roller bearings in their machines. Harsh materials must not be able to damage these bearings, and extreme temperatures and vibrations must not be able to make them fail.

The mining industry wants to keep equipment running, so they value maintenance that is easy and long replacement times. In large-scale mining equipment installations, shaft deflections are fixed by bearings with strong sealing systems and self-aligning features.

Uses in Cars and Transportation

Tapered roller bearings are used in automotive wheel hubs, transmissions, and differentials so they can handle high speeds and heavy loads. To meet the safety and performance standards for vehicles, these uses need exact tolerances in manufacturing and steady quality. The bearings must handle speeding, turning, and braking. They also have to keep the business running during long service periods.

Heavy-duty trucks and other vehicles use larger bearings to make sure that the fleet is reliable and can carry heavier loads.

Maintenance and Lifespan Optimization for Conical Roller Bearings

Active Methods for Monitoring

Vibration analysis, temperature monitoring, and lubricant analysis are all condition monitoring technologies that help maintenance programs find the first signs of bearing degradation. Noise and heat are signs of failure, as well as unusual vibration patterns that could mean that the lubrication is breaking down, dirt is getting in, or there are misalignment issues.

Regular inspection schedules should include checking the sealing systems, making sure there is enough lubrication, and looking over the mounting arrangements to make sure the best bearing performance over the entire operational lifecycle.

Installing and Lubricating: The Best Way to Make Sure It Is Done Right

Proper installation has a big impact on how well conical roller bearings work and how long they last. Exact ways of mounting stop stresses that could make the system fail too early. Choosing the right lubricant and putting it on the right way makes sure that there is enough film thickness even when the machine is running. Rough particles can't get into the bearing assembly and cause faster wear patterns if contamination is controlled during installation and maintenance.

In order to keep the best performance levels, lubrication schedules must look at load levels, speed ranges, and environmental factors. During service intervals, high-tech lubrication systems that can be monitored automatically help maintain the quality and quantity of the lubricant.

Procuring Conical Roller Bearings: What B2B Buyers Need to Know

Use These Criteria to Test Suppliers.

When procurement plans look at what suppliers can do, they consider things like how they make products, how they make sure quality, and how they offer technical support. The minimum order amounts, delivery times, and prices for both standard and custom bearing setups are all important things to consider. Established suppliers always deliver quality, as shown by statistical Process Control data and detailed testing records.

You need to plan how to ship goods, keep track of your stock, and help people in different places for global supply chains. These things make certain that there are always enough of the right parts for important tasks. You can be sure that you'll always get help with your equipment because the supplier is financially healthy and can stay in business.

Choosing things and changing them

Its load rating, how well it resists corrosion, and how well it works at high or low temperatures are some of the factors that determine whether to use stainless steel, standard steel, or an alloy. When you are thinking about different designs (like open vs. sealed), materials for the cage, and ways to lubricate it, you should think about the environments it will be used in and how easy it will be to keep clean.

For some tasks, customization can help them work better. This can be accomplished by altering the shape of the part's interior, adding specialized coatings, or creating sensor systems that monitor the part's condition. These features that improve the product and lower the cost can help explain why prices are higher.

Embedding Trust: Company Introduction and Product Service Information

Bearing Manufacturing Excellence at INNO

With almost 30 years of experience designing and making conical roller bearings, Luoyang INNO Bearing Co., Ltd. provides complete support for large bearing applications with non-standard sizes up to 5000 mm in diameter across markets around the world. Our unified method brings together R&D, exact manufacturing, and technical service support to provide tailored answers that meet the most difficult needs of the industry.

We can make both single-row and double-row configurations, and our high-tech quality control systems make sure that all product lines work the same way. The company has to do a lot of tests on their products to make sure they will work in important situations. They test the materials, the size, and the performance of the products.

High-Level Technical Skills

INNO Bearing specializes in custom engineering solutions that deal with the specific problems that come up in different fields, like wind energy, heavy machinery, mining, and power generation. To get the best performance and reliability out of your equipment, our technical team fully supports you by analyzing applications, helping you choose bearings, and making installation suggestions.

The company's quick shipping and flexible production systems can make standard catalog items as well as specialized custom designs, all with competitive lead times. Warranty coverage, technical help, and the ability to get replacement parts are all parts of after-sales support that make sure customers are happy and the equipment stays up and running.

Conclusion

Conical roller bearings are important parts of machines used in industry that need to handle a lot of weight and last a long time. Their adaptable design makes them useful for a range of conditions in a variety of fields, and they always work well even when conditions are tough. Understanding application needs, procurement factors, and maintenance best practices helps people make smart choices about how to get the best performance from their equipment.

Choosing the right bearing specifications and good suppliers in a strategic way has a direct effect on how well the business runs and how much it costs over its lifetime. INNO Bearing's wide range of skills and history of successful performance give people confidence in important bearing applications where performance and reliability are mandatory.

FAQs

How do I choose a conical roller bearing?

Consider temperature, environment, rotational speed, and radial and axial load when choosing a bearing. Determine service life, precision, and maintenance ease. Our technical team can provide application-specific advice based on operating conditions and performance goals.

How often should heavy-duty apps be maintained?

Duty cycles, dirt, and weight affect when to fix the machine. Heavily used applications require inspections after 1,000 to 8,760 hours. More frequent maintenance includes lubrication. Condition monitoring systems determine maintenance based on bearing condition rather than a schedule.

Can conical roller bearings handle high-speed work?

Conical roller bearings are usually used for heavy applications, but they can handle moderate to high speeds if made properly and lubricated. Speed is determined by bearing size, load, and temperature. Talking to bearing engineers ensures the best high-speed setup.

Partner with INNO Bearing for Superior Conical Roller Bearing Solutions

When you need help with bearings, INNO Bearing is there for you with the most knowledge and best manufacturing skills in the industry. We offer a lot of different products, including standard and custom conical roller bearings that are made to work in the toughest industrial settings. No matter if you need new bearings for old machines or custom-made parts for new ones, our technical team will help you with every step of the buying process.

Enjoy the perks of working with a conical roller bearing maker that focuses on quality, creativity, and customer happiness. Emailing us at sales@inno-bearing.com is the best way to talk about your exact needs and get more information on the best way to do things technically.

References

Harris, T.A. & Kotzalas, M.N. "Essential Concepts of Bearing Technology: Rolling Bearing Analysis, Fifth Edition." CRC Press, 2019.

ISO 281:2007 "Rolling bearings - Dynamic load ratings and rating life." International Organization for Standardization, Geneva.

Palmgren, A. "Ball and Roller Bearing Engineering." SKF Industries Inc., Third Edition, 1959.

Hamrock, B.J., Schmid, S.R., & Jacobson, B.O. "Fundamentals of Fluid Film Lubrication: Second Edition." Marcel Dekker Inc., 2004.

ABMA Standard 11-1990 "Load Ratings and Fatigue Life for Roller Bearings." American Bearing Manufacturers Association, Washington D.C.

Nélias, D., Dumont, M.L., Champiot, F., Vincent, A., Girodin, D., Fougères, R., & Flamand, L. "Role of Inclusions, Surface Roughness and Operating Conditions on Rolling Contact Fatigue." Journal of Tribology, Vol. 121, Issue 2, 1999.