Malaysia's industrial sector continues to grow rapidly, driving strong demand for Deep groove ball bearings sourced from China. Current trade indicators show that annual purchasing volumes remain substantial, reflecting the country's reliance on high-quality and cost-effective bearing Solutions. Key buyers span the automotive sector, industrial equipment distributors, and machinery suppliers serving the palm oil processing industry. These companies benefit from China’s competitive pricing and advanced manufacturing capabilities, securing reliable ball bearings used across Malaysia's diverse machinery applications - from energy facilities to heavy-duty mining operations.

Understanding Deep Groove Ball Bearings and Their Advantages for Malaysian Industries

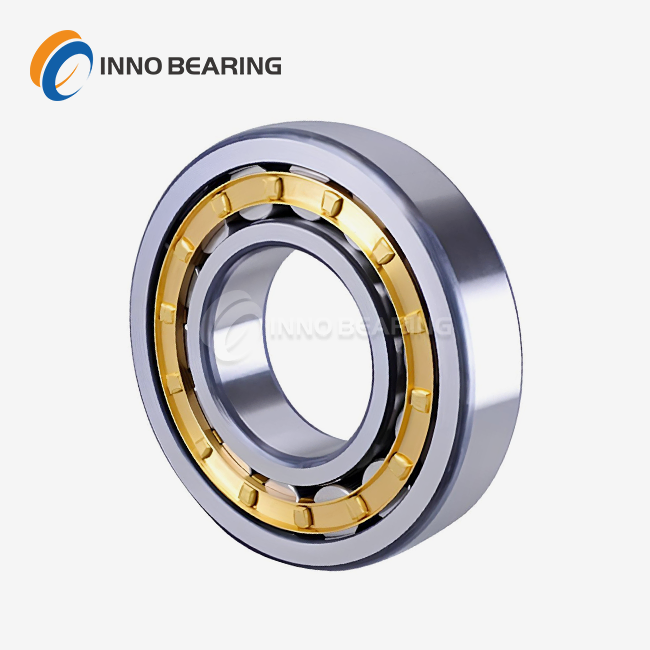

Deep groove ball bearings are one of the most useful and flexible types of bearings used in modern industry. The simple but effective design of these precision-engineered parts includes an inner ring, an outer ring with circular arc raceways, single-row steel balls, and a cage structure. Some variations have special closing systems that keep out contamination.

These bearings are very popular in Malaysian businesses because they can handle both radial loads and small axial loads at the same time. The simple design allows for high rotational speeds while still being easy to keep. This makes them perfect for Malaysia's humid tropical climate, where equipment dependability is very important.

These bearings are essential because they come in sizes ranging from 10 to 600 mm in diameter, 26 to 800 mm in diameter, and 8 to 150 mm in width. High-tech materials like GCr15 and GCr15SIMN chromium steel make sure that the steel will last in harsh conditions, and different precision grades, from normal P0/P6 to high-speed P4, can meet a wide range of performance needs.

Malaysian buyers really like how these bearings can be used in a lot of different situations. Quality ball bearings are needed for motor spindles that make textiles, water pumps that process palm oil, cooling fans that put together electronics, and car gears to work smoothly. Because this industry is so flexible, Malaysian procurement teams are always looking for dependable providers who can meet high quality standards.

Why Malaysian Buyers Prefer Chinese Manufacturers for Ball Bearing Solutions?

Shoppers in Malaysia trust Chinese makers because they always send good products at reasonable prices. The strategic benefits go beyond just low costs; they also include full manufacturing skills and an efficient supply chain.

Here are the main benefits that make Malaysians decide to buy things:

- Competitive Pricing Structure: Chinese manufacturers can offer price cuts of 20–40% compared to European competitors, while still keeping the same level of quality. Large companies and small Malaysian businesses can both buy things because of volume discounts and flexible minimum order amounts.

- Advanced Quality Control: The best Chinese bearing makers use strict testing methods that include checking the radial clearance, the stability of the seals, the accuracy of the steel ball arrangements, and the running noise levels. These steps for quality control are approved by foreign organizations such as ISO 9001 and IATF 16949.

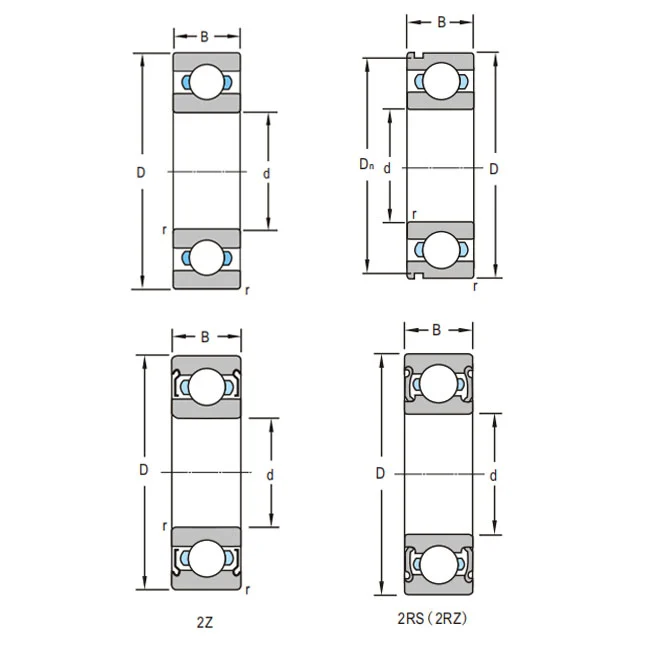

- Customization Options: Chinese suppliers are great at making non-standard deep groove ball bearings that fit the needs of Malaysian industries. Protect yourself from Malaysia's tough weather conditions, like high humidity and dust, with custom sealing choices like 2RS rubber seals or 2Z metal shields.

- Efficient Logistics: Being close to Malaysia means faster lead times and more affordable shipping options. A lot of Chinese companies have area distribution centers that make sure they can quickly meet urgent buying needs.

All of these benefits help Malaysian businesses cut costs in their supply chains while keeping their operations running smoothly. Chinese suppliers are the best choice for long-term procurement plans because they have both technical know-how and large manufacturing scale.

Comparing Ball Bearing Types for Optimal Malaysian Applications

Malaysian procurement professionals have to sort through a lot of different bearing choices to find the best ones for their needs. Knowing how different types of bearings work lets you make smart choices that make tools work as efficiently as possible.

When you compare deep groove ball bearings to Cylindrical roller bearings, you can see the trade-offs between speed and load capacity. Deep groove versions work best with moderate loads and are also very good at high speeds. This makes them perfect for Malaysian electronics manufacturing and car uses where rotational speed is more important than pure load capacity.

Angular contact bearings are better for situations with pure radial loads, but they are harder to install. Buyers from Malaysia usually only buy these for specific uses, like machine tool spindles or aircraft parts that need to be placed precisely.

In Malaysia's tropical climate, the choice between open and sealed bearing configurations has a big effect on how well they work. Sealed options with 2RS rubber protection are important for keeping out water during the monsoon season, while open bearings are better at removing heat from high-temperature environments like steel working equipment.

Choosing the right materials also affects how well they work. The standard GCr15 chromium steel is very durable for most uses. However, special alloys like 20Cr2Ni4A are better at resisting corrosion for marine and offshore uses that are popular along Malaysia's long coastline.

Quality Assurance and Performance Optimization for Malaysian Industrial Conditions

To get the best bearing performance in Malaysia's tough industrial setting, you need to pay attention to both quality controls during procurement and regular maintenance. Because of the tropical climate and the demanding nature of many industrial uses, proactive quality control methods are needed.

In Malaysia's precision manufacturing areas, measuring things correctly becomes very important. With tolerances of ±0.001mm, automated production lines and CNC machines can make sure that parts fit and work correctly. Malaysian buyers should make sure that providers follow these high standards for accuracy by using certified measuring tools and clear quality procedures.

Standardized procedures for inspecting materials protect against fake goods that could damage equipment. Testing for hardness (HRC 60–64), analyzing the chemical make-up, and checking the metal's structure all give trust in the material's integrity. When buying in bulk for important tasks like maintaining wind turbines or fixing up mining equipment, these quality checks become even more important.

In Malaysia, where humidity is high, proper lubrication techniques make deep groove ball bearings last longer. To get steady performance over long operational cycles, it's important to use the right grease formulations that don't absorb water and keep their viscosity at high temperatures. Regular inspection schedules that are tailored to the area's conditions help find problems before they become expensive machine failures.

Malaysian procurement plans also need to pay attention to supply chain risk management. Setting up relationships with several qualified suppliers, keeping strategic inventory levels, and putting in place quality tracking systems can help keep production schedules from getting thrown off.

Industries Driving Malaysian Demand for Precision Ball Bearings

Malaysia's wide range of industries generates strong demand across many areas, each with its own unique needs that affect how goods are bought and how suppliers are chosen.

An important part of the market that needs bearings that can handle high temperatures and corrosive conditions is the palm oil processing business. Processing machines like centrifuges, conveyors, and extraction tools need sealed bearings with special lubricants that keep working even when they are exposed to acids and high temperatures.

In order to make electronics, especially semiconductors, you need bearings that are very clean, don't let out a lot of gas, and rotate precisely. In cleanroom settings, these uses often call for ceramic ball choices and special cage materials that keep things from getting dirty.

Bearings that meet strict car quality standards are needed for Malaysia's auto industry, which is led by companies like Proton and Perodua. For passenger comfort, bearings that are both durable and quiet are needed in uses like electric motors, transmission parts, and fans that cool engines.

As the green energy industry grows, especially solar panel production and wind turbine installations, there is a need for large-format bearings that can handle heavy loads and keep their accuracy for long periods of time. Often, these uses need custom bearing solutions that are made to fit the needs of renewable energy tools.

Conclusion

Malaysia's industrial growth is still driving demand for high-quality deep groove ball bearings. Chinese manufacturers are becoming the preferred suppliers because their prices are affordable, they can make advanced products, and their quality standards are reliable. People in Malaysia who buy things can make smart choices that save them money and improve performance by knowing the technical specs, application needs, and quality control procedures. The partnership between Malaysian businesses and Chinese bearing makers is a strategic benefit that helps the growth of industries in many areas, from making cars to building infrastructure for renewable energy.

FAQs

How long does it usually take to get a lot of deep groove ball bearings from a Chinese manufacturer?

Depending on the amount and specifications, standard bearing orders usually take between 15 and 30 days to be made and delivered. Custom bearings may take 20 to 45 days, but rush orders can usually be processed faster in 7 to 10 days. Lead times are affected by things like the size of the bearing, the level of precision needed, the sealing standards, and the current production schedules.

How do the types of materials used affect how well bearings work in Malaysia's humid climate?

The choice of material has a big effect on how well something works in places with a lot of humidity. For general use, standard GCr15 chromium steel works very well, but for coastal uses, specialized stainless steels are better at resisting corrosion. Brass and other cage materials don't rust as easily as stamped steel, which makes them better for damp places.

When Malaysians buy bearings from China, what kinds of quality guarantees should they look for?

Some important certifications are ISO 9001 for quality control systems, IATF 16949 for automotive uses, and RoHS compliance for electronic uses. Depending on what it will be used for, it may need extra certifications like API specifications for oil and gas applications or marine certifications for offshore tools.

INNO Bearing: Your Trusted Deep Groove Ball Bearings Supplier

Luoyang INNO Bearing Co., Ltd. stands ready to serve Malaysian buyers seeking reliable, high-performance bearing solutions backed by nearly three decades of manufacturing excellence. Standard and custom deep groove ball bearings are part of our wide range of products, which are made to meet the specific needs of Malaysian businesses.

Because we use advanced production techniques, we can make custom bearings with a diameter of up to Ά5000mm for specific uses in the mining, power generation, and heavy machinery industries. Our bearings work very well in Malaysia's toughest industrial settings because they can withstand temperatures up to 500°C and precision grades that reach the P4 rating.

Quality assurance is still a big part of what we offer, and we're able to get 99.9% qualification rates by using thorough testing methods like vibration analysis and models of 50,000+ hour lifespans. Our ISO 9001 and IATF 16949 certifications show that we follow the world quality standards that buyers in Malaysia expect from their suppliers.

Our flexible supply chain lets Malaysian procurement teams send standard goods out within 48 hours and get custom solutions with short lead times. Our global logistics network guarantees dependable arrival times that meet the needs of Malaysian production while providing flexible FOB and CIF terms.

Find out what a difference precise engineering and committed customer service can make in how you buy bearings. Get in touch with us at sales@inno-bearing.com to talk about your unique needs and find out how our deep groove ball bearings can improve the reliability and operational efficiency of your equipment.

References

Malaysian Industrial Development Authority. "Industrial Equipment Import Statistics and Market Analysis." Annual Trade Report, 2023.

Asia-Pacific Bearing Manufacturers Association. "Quality Standards and Certification Guidelines for Industrial Bearings." Technical Publication Series, 2023.

International Organization for Standardization. "Precision Ball Bearings - Dimensional Accuracy and Performance Requirements." ISO Technical Specification 492, 2022.

Malaysian Palm Oil Board. "Equipment Reliability Standards for Processing Machinery." Industry Guidelines, 2023.

Southeast Asian Automotive Parts Association. "Bearing Quality Requirements for Automotive Applications." Industry Standards Manual, 2022.

China Bearing Industry Association. "Export Quality Control and International Compliance Standards." Manufacturing Guidelines, 2023.