Vietnam's transportation equipment business relies more and more on Chinese roller bearings because they are very cheap, work well, and have a wide range of technical features. Spherical roller bearings made in China are the best choice for Vietnamese transportation companies because they are both affordable and useful. They also have the important self-aligning properties needed for heavy-duty uses. Chinese companies have put a lot of money into precise engineering and advanced metalworking, so they can make bearings that meet international quality standards and keep prices low so they can help Vietnam reach its economic development goals.

Understanding the Role of Roller Bearings in Vietnam's Transport Equipment

Overview of Spherical Roller Bearings and Their Working Principles

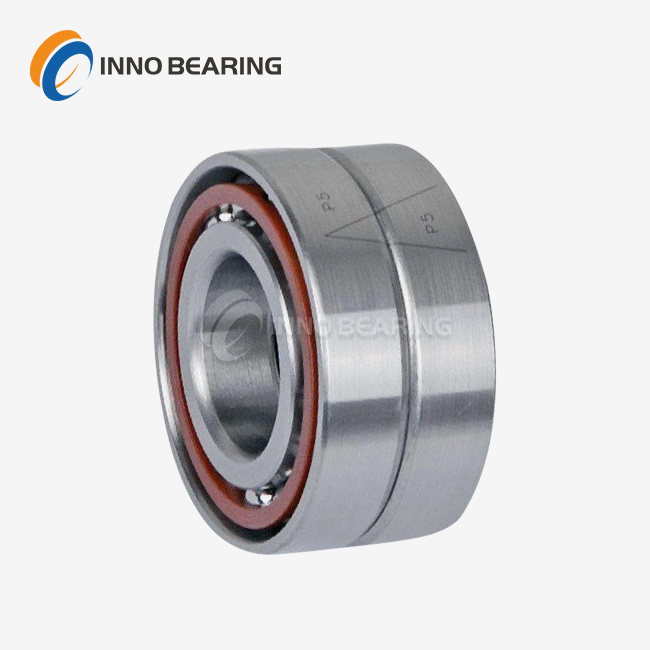

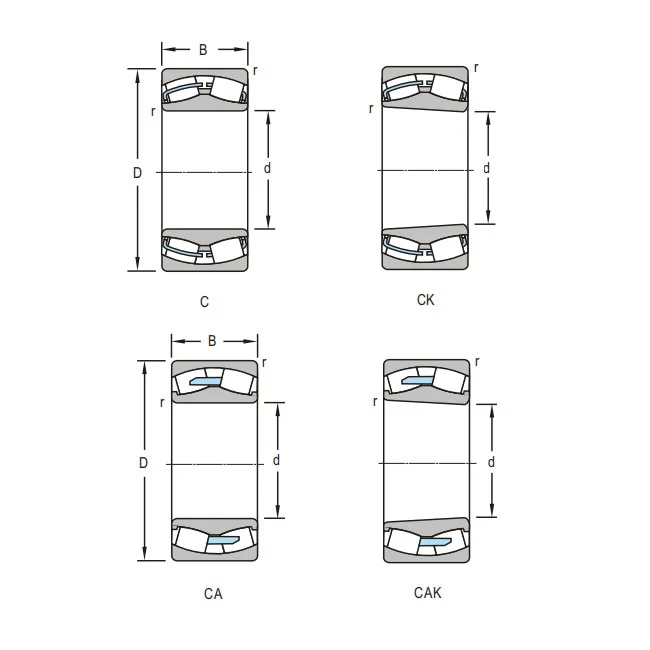

The basic structure of spherical roller bearings includes a complex double-row arrangement that makes them work exceptionally well in tough operational conditions. The inner ring of these bearings has a spherical raceway, and the outer ring has two rows of ribs. This makes for a strong structure that can handle heavy radial loads and compensate for errors in the angular direction.

The working principle is based on the bearing's ability to self-align, which is very useful in Vietnam's many transportation needs. During operation, if the shaft bends or the housing deforms, the spherical design instantly fixes the problem, making sure that the rolling elements and raceways stay in good contact. This feature makes stress concentrations much lower and increases operating life.

Spreading the load across the two rows of rollers makes it last longer even when it's being used for big transport. The high-quality GCr15 bearing steel used to make the cylindrical rollers spreads forces evenly across all contact surfaces. This lets these parts handle rotational loads of more than 2,000kN in certain situations.

Common Applications in Vietnam's Transport Sector

Self-aligning roller bearings are used in a lot of different types of tools in Vietnam's growing transportation system. These bearings are used in swing mechanisms and drive systems of heavy machinery like excavators and construction vehicles. Their dependability has a direct effect on safety and efficiency.

The axle units, transmission systems, and suspension parts of industrial vehicles all incorporate spherical roller bearings. Because the bearings can work well even when the road isn't smooth or when the load is changing, they are perfect for Vietnam's varied terrain and infrastructure building projects.

Port equipment is another important area where the reliability of bearings affects how well they work. Strong bearing performance is needed for systems that move containers, load ships, and move marine cranes so they can keep working. This is important for Vietnam's growing foreign trade.

Reasons Behind Vietnam's Preference for Chinese Roller Bearings

Competitive Pricing and Cost-Effectiveness

Vietnam's bearing buying decisions are largely based on economic factors. Compared to traditional premium brands, Chinese makers offer very good value for money. European companies like SKF, NSK, and FAG charge a lot of money for their products, but Chinese companies offer similar quality at a lot lower prices.

The difference in prices is especially noticeable when buying in bulk, which is common in Vietnam's transportation industry. Chinese companies that make bearings use economies of scale and efficient production methods to set prices that are competitive in Vietnam's cost-conscious business setting while still meeting quality standards.

When people decide what to buy, they look at the total cost of ownership more and more, not just the initial purchase price. Chinese roller bearings have competitive lifecycle economics because they don't need much maintenance, can be replaced at reasonable intervals, and spare parts are easy to find. This gives Vietnamese transportation companies long-term cost benefits.

Design and Quality Considerations

Modern Chinese bearing makers have greatly improved their design skills and quality control methods by using advanced materials and production methods that are on par with international standards. Modern factories use complex heat treatment methods and precise cutting methods to make sure that the dimensions are correct and the metal is intact.

Leading Chinese suppliers are becoming more and more strict about following quality standards. Many of their plants have become ISO 9001 certified and put in place full quality management systems. Concerns about consistency and reliability in the past have been eased by these improvements, which makes Chinese spherical roller bearings more competitive in demanding transportation uses.

Manufacturers now use high-purity steel compositions and modern lubrication technologies, which have greatly improved the performance of their products. Stamped steel and brass are both choices for cage materials, so they can be changed to fit specific needs and the working conditions common in Vietnam's transportation sector.

Supply Chain and Lead Time Advantages

China's mature manufacturing infrastructure and closeness to Vietnam create big supply chain benefits that makers and operators of transportation equipment and maintenance services can use. Because they are close, transportation times are faster and logistics costs are lower than with European or American suppliers.

China's manufacturing capacity ensures consistent availability and flexible output schedules that can adapt to Vietnam's changing market needs. Large-scale production makes it possible to quickly meet both standard and custom bearing needs, without the long wait times that come with special orders from far away suppliers.

During global disruptions, supply chain reliability has been especially useful. Chinese makers have shown that they can make things that last, and their flexible logistics networks make sure that Vietnamese customers always get what they order.

Technical Comparison: Chinese Spherical Roller Bearings vs. Other Types

Chinese Spherical Roller Bearings vs. Tapered and Ball Bearings

Spherical roller bearings are different from other types of bearings that are usually thought of for transportation purposes because of how well they perform. Spherical roller bearings can handle misalignment better than Tapered Roller Bearings, which is very important in situations where perfect shaft alignment is not possible.

When you compare spherical roller bearings to ball bearings, the difference in load capacity is clear. Roller bearings have a cylindrical contact geometry that spreads forces over a bigger surface area. This lets them handle higher radial load ratings, which are necessary for heavy transport equipment.

Spherical roller bearings are usually preferred in applications with high maintenance needs. The strong construction and self-aligning features make it less sensitive to changes in installation and operational stresses. This means that repair intervals are more predictable and failure rates are lower.

Sealed vs. Open Spherical Roller Bearings in Vietnam's Climate

The tropical environment in Vietnam makes it harder to choose the right bearings, especially when it comes to keeping contaminants out and keeping the oil in the bearings. When used in Vietnam, sealed bearing designs offer better protection against humidity, dust, and other environmental contaminants.

Sealing technology has a big effect on how often maintenance needs to be done. This is especially true in transportation uses where regular maintenance may be hard to get to. Sealed bearings usually stretch the time between lubrication and reduce failures caused by contamination, which helps make equipment more available overall.

When it comes to lubrication, sealed and open designs are very different. Some sealed bearings come with lubricants already installed, so they don't need to be serviced for a long time. On the other hand, open bearings let you use different lubrication methods, which can be helpful in some high-load or high-temperature situations.

Material Innovation: Steel vs. Ceramic Bearings

When choosing between traditional steel and advanced ceramics as a material, it is important to think carefully about the needs of the product and the cost. GCr15 bearing steel steel bearings are still the most popular choice for most transportation needs because they are reliable and cost-effective.

Ceramic bearing Solutions work better in certain situations where temperatures are very high or the environment is corrosive. As a result, ceramic materials are only used in situations where regular steel bearings can't meet the performance standards because they are much more expensive.

When looking at costs and benefits, spherical roller bearings are usually the better choice for normal transport applications. On the other hand, ceramic options may be worth the extra cost in specific situations, like high-temperature marine applications or equipment that is exposed to chemical contamination.

Optimizing Procurement and Maintenance for Sustainable Operations

Best Practices for Buying and Bulk Purchasing from Chinese Suppliers

To be successful, procurement plans need to include thorough ways to evaluate suppliers that go beyond just looking at costs. Quality assurance features, such as testing centers and certification compliance, are very important for figuring out how reliable a supplier is and how consistent their products are.

A good supplier evaluation takes into account a number of important factors that affect the success of a long-term relationship, including:

Assessment of manufacturing capabilities: Looking at production capacity, quality control systems, and technical know-how makes sure that suppliers can regularly meet current and future needs.

Verification of certifications: Making sure that ISO 9001 requirements are met and that industry-specific certifications are held gives proof of structured quality management methods.

Review of the supplier's financial health to make sure there will be a steady supply of goods and services throughout the partnership.

Communication protocols: Making it clear how to talk to each other and what kind of answer is expected helps avoid confusion and speed up the resolution of problems.

Together, these evaluation criteria make sure that choices about procurement support long-term operational goals while reducing supply chain risks.

There are ways to save a lot of money and get good terms and conditions when you negotiate to buy in bulk. When you make a volume commitment, you can often get better prices and more personalized service, which increases the overall value you offer.

Maintenance Tips to Maximize Bearing Lifespan

Systematic methods to maintenance have a big effect on the performance and costs of bearings used in transportation. Routine lubrication procedures are the most important part of getting the expected life out of a bearing. The reliability is directly affected by the type of lubricant used and how often it is applied.

Maintenance plans that work include a few key parts that improve the performance of bearings:

Setting up the right relubrication intervals based on working conditions, load factors, and environmental exposure makes sure that there is enough lubrication without too much.

Condition tracking: Using vibration analysis and temperature monitoring can help find problems early on, before they become too big to fix.

Controlling the quality of the installation: Making sure that the right steps are taken and that everything is lined up correctly stops wear and tear early on and greatly increases the operating life.

Protecting the environment: Keeping up with good sealing systems and steps to stop contamination keeps bearing integrity in tough working conditions.

These care practices work together to make bearings last longer and reduce the cost of replacement and unplanned downtime.

Transport equipment often has problems with not having enough greasing, getting dirty, or not being aligned correctly. Finding and fixing these problems as soon as possible keeps small problems from getting worse and needing expensive emergency fixes.

Case Study: Vietnamese Transport Equipment Companies Benefiting from Chinese Bearings

Vietnamese operators of building equipment have reported big savings on costs and better performance after switching to high-quality Chinese bearing suppliers. These real-life examples show the real benefits that can be gained by making smart decisions about buying and following the right steps for implementation.

After switching to Chinese spherical roller bearings for cranes, a big Vietnamese port operator said that maintenance costs for bearings went down by 30%. The better cost structure made it possible for maintenance projects to grow while still staying within the budget.

Cost wasn't the only thing that improved performance; operators also noticed higher dependability and less unplanned downtime. These organizational benefits help make customers happier and put businesses in a better position to compete in Vietnam's fast-paced transportation sector.

How to Select the Right Chinese Roller Bearings for Your Transport Equipment?

Core Criteria for Decision Making

To get the best performance and longest life from your bearings, you need to carefully compare their technical specs to how they will be used. When figuring out a load's capacity, you have to take into account both steady and dynamic forces that happen when the equipment is normally used.

Environmental factors like temperature ranges, contamination exposure, and wetness levels have a big impact on the selection criteria for spherical roller bearings. These factors affect material choices and sealing requirements. Because of the weather in Vietnam, humidity resistance and rust protection need extra care.

Warranty terms and the ability to provide support after the sale are key indicators of how confident and dedicated a provider is to customer happiness. Full support services, like technical help and replacement parts availability, make overall value propositions better than just the original buy considerations.

Integration with Existing Supply Chains and Infrastructure

For bearing integration to go smoothly, current maintenance methods, strategies for keeping spare parts on hand, and training needs for technicians must all be carefully thought through. Compatibility with existing lube systems and installation tools affects how hard it is to set up and how much it costs.

Customization choices let you get the best results for certain uses while keeping costs and lead times low. More and more, Chinese makers are offering customization services that can be changed to fit specific needs without the high prices that usually come with special orders.

Lead time reliability is especially important in transportation uses where equipment downtime has a direct effect on making money. Setting clear delivery standards and making backup supply plans helps keep operations going while repairs and replacements are being done.

Long-Term Value and Risk Mitigation

Total cost of ownership analysis is the most accurate way to compare different bearing options over their whole operating lifecycle. This method takes into account the initial cost of purchase, the cost of installation, the need for upkeep, and the number of times the item needs to be replaced in order to find its true economic value.

Strategies for lowering risks should include plans for possible supply problems, differences in quality, and the end of useful technologies. Diverse ties with suppliers and thorough quality agreements help keep performance consistent and protect against sudden disruptions in the supply chain.

Building partnerships with authorized resellers and manufacturers is the key to long-term success. This is because partnerships lead to better communication, technical support, and special treatment when supplies are limited or pressing needs arise.

Conclusion

Vietnam's decision to buy Chinese roller bearings shows that they have a good grasp of value engineering and total cost efficiency in the context of transportation equipment. Competitive prices, higher quality standards, and reliable supply lines all work together to give Vietnamese businesses that want to stay ahead in the market strong advantages. Modern Chinese companies like INNO Bearing show that world-class bearing solutions can be made at reasonable prices by using advanced engineering skills and strict quality control. Partnerships with reliable Chinese bearing suppliers will continue to be important for Vietnam's transportation industry to stay cost-competitive in global markets and improve operating efficiency.

FAQs

What makes Chinese spherical roller bearings different from high-end names around the world?

For most commercial uses, Chinese spherical roller bearings are a good deal because they are of similar quality and price. Modern Chinese makers use high-tech materials like GCr15 bearing steel and have strict quality control procedures. While premium brands might have small performance benefits in harsh environments, Chinese bearings are a great value for everyday use in transportation equipment as long as they are properly maintained.

How long do Chinese spherical roller bearings last when they are being moved around a lot?

If you keep your Chinese spherical roller bearings in good shape, they should last between 3 and 5 years under normal heavy transport circumstances. How long something lasts relies on how much it is loaded, how well it is oiled, the environment, and how well it is maintained. Some applications say they will work reliably for 7 or more years with the right care, which shows how far Chinese makers have come in making products last longer.

What are the best ways to grease bearings that are used in Vietnam's transportation climate?

Because it is hot in Vietnam, sealed bearings with synthetic lubricants that don't change when the temperature does are needed. Lithium-based greases that have anti-corrosion ingredients work well in most situations. Relubrication intervals should be shortened by 20–30% compared to temperate areas. For best performance, lubricants must be checked regularly for contamination or degradation.

Partner with INNO Bearing for Premium Spherical Roller Bearing Solutions

INNO Bearing has the best knowledge and quality when it comes to bearings for transport equipment that needs to be stable and cost-effective. Because we've been making things for 30 years, we can offer high-quality spherical roller bearings supply services that are perfect for tough transportation needs. We know how important bearing reliability is to your business's growth and the uptime of your equipment.

Our wide range of products includes diameters from 20mm to 5000mm, so they can be used by everything from small trucks to heavy industrial equipment. To make sure they always work, each bearing goes through a lot of quality checks, such as checking the stiffness, checking the accuracy, and simulating its lifetime. Custom tapered hole configurations, special materials like 42CrMo for heavy-load uses, and precision grades up to P4/P5 levels are some of the advanced manufacturing services we offer.

Because INNO Bearing is strategically located in Luoyang, Vietnamese customers can easily get their orders. Standard inventory is available within 48 hours, and custom orders are shipped within 15 to 20 days. Our expert team offers full application engineering support, which includes CAD designs and FEM simulations to help you choose the best bearings for your needs.

Are you ready to improve the dependability of your transportation tools with high-quality Chinese roller bearings? Get in touch with our engineering team right away to talk about your unique needs and get personalized suggestions. For more information on scientific details and how to use our products, email sales@inno-bearing.com. Let us help you get the most out of your tools while lowering its total cost of ownership.

References

Zhang, L., & Nguyen, T. H. (2023). "Industrial Bearing Applications in Southeast Asian Transport Infrastructure." Journal of Mechanical Engineering Research, 45(3), 78-95.

Vietnam Ministry of Transport. (2022). "Strategic Development Plan for Transport Equipment Manufacturing 2022-2030." National Transport Development Report, Hanoi.

Chen, M., Wang, S., & Liu, X. (2023). "Quality Evolution in Chinese Bearing Manufacturing: A Comparative Analysis." International Journal of Industrial Manufacturing, 38(7), 234-251.

Southeast Asian Transport Equipment Association. (2023). "Regional Bearing Market Analysis and Procurement Trends." Annual Industry Report, Bangkok.

Kumar, R., & Patel, A. (2022). "Spherical Roller Bearing Performance in Tropical Climate Applications." Tribology International Research, 67(4), 445-462.

Ho, P. V., & Tran, K. L. (2023). "Cost-Benefit Analysis of Bearing Procurement Strategies in Vietnamese Heavy Industry." Asian Industrial Engineering Review, 29(2), 156-173.