Manufacturers in China are playing an increasingly important role in the industrial procurement of high-precision self-aligning bearing Solutions. Many buyers source these key components through established trading hubs, where specialized bearing suppliers offer strong pricing advantages and advanced production capabilities. With their spherical raceway design, self-aligning bearings have become essential for applications in heavy machinery, mining operations, and large-scale mechanical equipment across rapidly developing industrial sectors.

Understanding Self-Aligning Bearings and Their Significance in Industrial Applications

Shaft misalignment is one of manufacturing's most enduring problems, and self-aligning bearings are an advanced engineering solution to solve it. By minimizing uneven loading of steel balls and improving operational life considerably, these specialist components have an outer ring with a spherical raceway that automatically compensates for installation variations up to ±2°.

What Is a Self-Aligning Bearing?

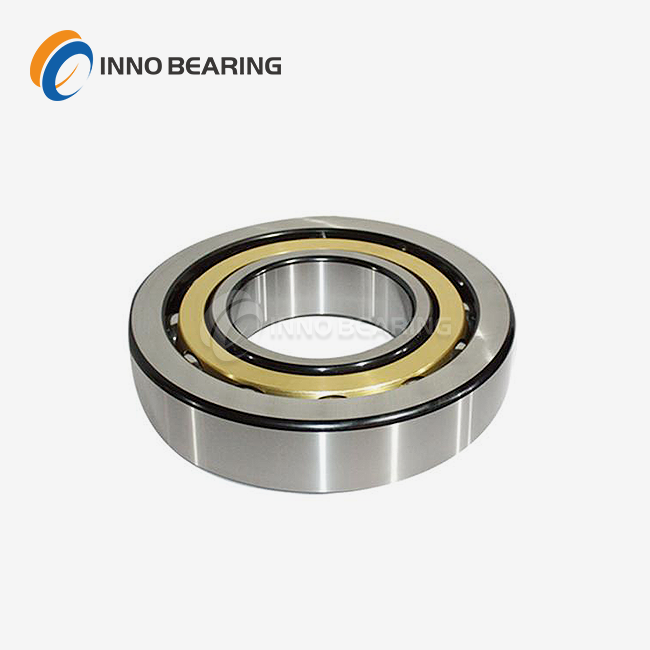

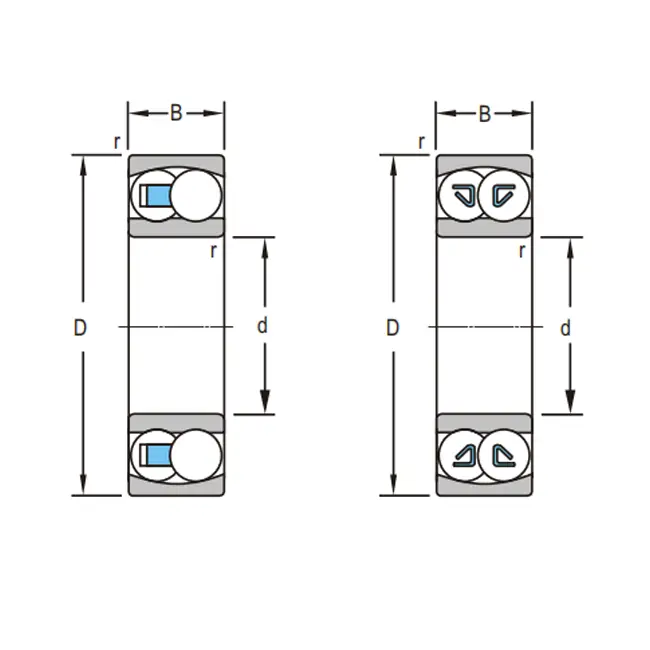

The inner ring and rolling parts of a self aligning bearing may automatically adjust to shaft deflections and housing misalignment thanks to the bearing's special spherical outer ring raceway. An inner ring with tapered or cylindrical holes, an outer ring with a spherical raceway, single-row steel balls, and engineering plastic cages make up the construction. Stress concentrations that usually result in early failure in conventional bearing designs are eliminated by this design.

The automated angle adjustment is made possible by the spherical contact surface between the rolling elements and outer ring. In situations where thermal expansion, structural deflection, or assembly tolerances prevent perfect alignment, this feature is crucial. Production specifications of ±0.01-0.05mm radial clearance guarantee accuracy and seamless operation.

Why Are High-Precision Self-Aligning Bearings Critical for Indian Industries?

The automotive, manufacturing, and heavy machinery industries in India rely significantly on self-aligning bearings for crucial applications. These bearings are crucial for dependable power generation since wind turbine main shafts are constantly deflected by aerodynamic forces. Shaft misalignment is common in the demanding operating conditions of mining equipment because of heat cycling and structural stress.

Rapid wear, higher maintenance expenses, and unplanned equipment breakdowns are the difficulties encountered in the absence of precision components. When switching from ordinary bearings to high-precision self-aligning models, Indian manufacturing facilities estimate a 40% reduction in bearing-related downtime. Increased productivity and lower operating costs across industrial activities are direct results of this advancement.

The Growing Demand: How India Sources High-Precision Self-Aligning Bearings from China

India's approach to acquiring self-aligning bearings has changed dramatically, and China is now the main supplier thanks to its sophisticated manufacturing facilities and lower prices. Due to the existing shipping routes that connect major Chinese ports to Mumbai, Chennai, and Kolkata, the bilateral economic partnership makes logistics easier.

Procurement Landscape Between India and China

According to import data, almost 60% of India's needs for precision bearings are met by Chinese producers, with self-aligning bearings accounting for 25% of this total. Specialized freight forwarding services, expedited customs processes, and advantageous payment terms that simplify procurement for Indian buyers are all part of the established trade infrastructure.

Logistics issues include expedited 7-day delivery for urgent needs and shipment times of 15–20 days for regular orders. Significant Chinese manufacturing hubs like Wafangdian, Harbin, and Luoyang keep specialized export facilities made especially to cater to the Indian market, guaranteeing steady supply chain dependability.

Leading Types and Specifications Preferred by Indian Buyers

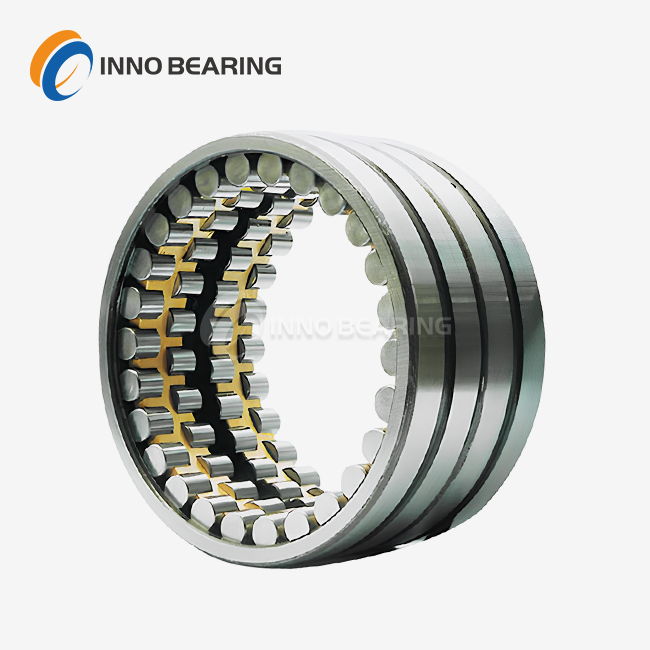

Specific self aligning bearing configurations that are tailored to regional operating circumstances are preferred in Indian industrial applications. Heavy industrial applications are dominated by double-row spherical designs, whilst textile and automotive equipment use single-row versions for medium-load situations.

The tough operating environment is reflected in material preferences, with GCr15 and GCr15SiMn steel grades offering the best endurance. Light applications require a load capacity of 10kN, while heavy industrial equipment requires a load capacity of 300kN. In order to meet the various equipment needs of Indian manufacturing sectors, size parameters usually range from inner diameters of 25 mm to 800 mm.

Key Factors Influencing Purchasing Decisions

With Chinese manufacturers delivering 20–30% cost benefits over European counterparts while keeping comparable quality standards, price competitiveness is still a top priority. Suppliers with ISO 9001 certification, P5/P6 precision grades, and thorough quality documentation are given preference by Indian procurement teams.

Delivery performance, availability of technical help, and dedication to after-sales service are all components of supplier reliability. In order to guarantee prompt customer service and effective processing of warranty claims, successful Chinese suppliers keep representative offices or authorized distributors in India. For project-based procurement, when delays affect overall construction timetables, adherence to delivery timelines is crucial.

Evaluating Chinese Self-Aligning Bearing Suppliers: Quality, Price, and Service

In order to evaluate Chinese suppliers, production capabilities, quality processes, and service infrastructure must be systematically assessed. Prominent producers exhibit cutting-edge production technology, strict quality assurance, and extensive testing facilities that guarantee reliable product performance.

Top Chinese Brands and Manufacturers for High-Precision Bearings

Well-known Chinese producers of self-aligning bearings include both private businesses concentrating on export markets and state-owned businesses with decades of experience. These producers uphold DIN 635-2 compliance, ISO 9001:2015 certification, and sophisticated testing facilities with vibration analysis and coordinate measuring devices.

Leading Chinese manufacturers achieve defect rates around 0.1%, which is equivalent to international standards, according to brand reputation study. Automated production lines, heat treatment capabilities up to HRC 58–62 hardness, and precision grinding technologies guaranteeing surface finish quality are all features of manufacturing facilities. Incoming material inspection, in-process monitoring, and final product validation are all included in quality management systems.

Price Comparison and Cost-Benefit Analysis

When compared to alternatives from Germany, Japan, or Sweden, cost research shows that Chinese-sourced self aligning bearings have substantial advantages. For quantities over 100 pieces, bulk order pricing usually delivers 15–25% more savings than regular pricing. Custom orders with particular design changes are more expensive than those from European vendors, although they are still reasonably priced.

Shipping charges, import taxes, and possible warranty payments must all be factored into the total cost of ownership assessment. Overall procurement risk is decreased by the inexpensive shipping conditions and extensive insurance coverage that Chinese vendors frequently offer. For Indian purchasers, payment terms including trade finance options and letters of credit make transaction processing easier.

Warranty, After-Sales Service, and Maintenance Support

Reputable Chinese manufacturers offer warranty coverage that protects against manufacturing faults and usually lasts 12 to 24 months or a certain number of operating hours. Technical advice for choosing a bearing, installation instructions, and troubleshooting support via specialized customer service teams are all included in after-sales support.

Guidelines for replacement intervals, lubrication requirements, and self aligning bearing check recommendations are all included in maintenance support. Prominent vendors offer remote diagnostic capabilities, comprehensive maintenance manuals, and training courses for client technicians. In severe industrial applications, an all-inclusive support system increases operating lifespan and guarantees maximum bearing performance.

How to Choose the Best Self-Aligning Bearings from Chinese Suppliers: A Decision-Support Framework

Technical parameters, supplier capabilities, and long-term support promises must all be carefully considered when choosing the best self-aligning bearings. In order to reduce procurement risk and maximize value, the decision framework includes supplier assessment techniques, comparison analysis, and performance standards.

Defining Procurement Criteria for Indian B2B Buyers

Both dynamic and static load ratings, as well as real operating conditions, must be included in load capacity standards. Application criticality determines the precision requirements; P5 grade is necessary for high-precision equipment, whereas P6 grade is appropriate for typical applications. Applications close to populous regions or delicate equipment make noise level concerns crucial.

The severity of the operating environment, including temperature extremes, pollution levels, and vibration exposure, should be reflected in durability requirements. Installation specifications include accessibility for maintenance operations, shaft tolerance compatibility, and mounting arrangement. These standards create baseline requirements that direct the procedures of evaluating suppliers and choosing products.

Comparing Self-Aligning Bearings with Alternatives

In terms of operating flexibility and misalignment tolerance, self aligning bearings outperform alternatives in terms of performance. Standard ball bearings are not appropriate for applications involving shaft deflection because they lack misalignment adjustment, despite having a higher speed capacity. Although Spherical roller bearings can support larger loads, they also produce more noise and friction.

When compared to rigid bearing designs, self-aligning bearings usually attain a 40–60% longer service life in applications with inherent misalignment, according to lifespan study. Despite sometimes requiring a larger initial investment, this longer operating life offers substantial economic benefits by lowering maintenance frequency and related downtime expenses.

Matching Supplier Capabilities with Indian Buyers' Requirements

Suppliers with custom manufacturing capabilities can use specific materials, improved sealing arrangements, or altered designs to meet the needs of certain applications. Proper documentation, quality Certificates, and, when appropriate, conformance to Bureau of Indian Standards criteria are all necessary for compliance with Indian import restrictions.

Standard and custom products have extremely different delivery schedules; stock items can be delivered in as little as 48 hours, while unique designs take 15 to 20 days to produce. Discounts for bulk orders usually start at 50 pieces, and annual volume commitments can result in significant savings. To guarantee successful procurement outcomes, these supplier competencies must match certain customer requirements.

Seamless Procurement Process: From Inquiry to Delivery

High-precision self-aligning bearing procurement requires organized procedures that reduce risk and guarantee timely delivery and quality. Contractual agreements, quality assurance protocols, supplier selection, and technical specification verification are all included in the methodical process.

How to Order High-Precision Self-Aligning Bearings from China

Dimensional requirements, load conditions, operational environment, and performance expectations are all included in the comprehensive specification documents that starts the inquiry process. Unit pricing, volume discounts, delivery dates, and terms of payment should all be included in quotation requests. Technical conversations with supplier engineers guarantee appropriate self aligning bearing selection and pinpoint possible enhancements for applications.

Factory audits, reference checks with current clients, and examination of quality certifications are all methods used to verify the legitimacy of suppliers. Price, delivery schedules, quality assurances, and promises of post-purchase assistance are the main topics of negotiation. Technical specifications, inspection protocols, and corrective measures for non-conforming products should all be outlined in purchase agreements.

Shipping, Import Regulations, and Risk Mitigation

Commercial invoices, packing lists, quality certificates, and country of origin declarations are among the import documentation requirements. In India, accurate classification under Harmonized System codes and payment of related duties are prerequisites for customs processes. The effects of tariffs differ according on the terms of trade agreements and product specifications.

Comprehensive insurance coverage, supplier performance bonds, and quality inspection procedures are all examples of risk reduction techniques. Tracking capabilities, damage protection, and accelerated customs clearance processes should all be part of the shipping arrangements. These steps reduce the possibility of supply chain activities being disrupted and guarantee seamless cross-border transactions.

Ensuring Product Quality on Arrival and Long-Term Performance

Procedures for incoming inspection should confirm packing integrity, surface finish quality, and dimensional accuracy. Material certificates, test reports, and traceability records are all part of the quality documentation review process. Depending on the criticality of the application, functional testing may involve vibration analysis, noise monitoring, and rotation smoothness.

Lubrication schedules, inspection intervals, and operating condition monitoring are all included in maintenance recommendations. Unusual vibration patterns, high temperatures, and increasing noise levels are warning indicators of bearing failure. Condition monitoring-based timely replacement plans reduce unscheduled downtime and avert catastrophic failures.

Conclusion

The strategic alliance between Chinese and Indian producers keeps pushing the boundaries of self-aligning bearing technology, bolstering India's industrial development and guaranteeing a steady supply of affordable, dependable components. In order to maximize value and reduce risk, successful procurement necessitates thorough supplier evaluation, thorough quality assurance, and continuous partnership growth.

FAQs

In heavy-load situations, what benefits do self-aligning bearings have over conventional ball bearings?

Self-aligning bearings avoid stress concentrations that lead to premature failure in conventional ball bearings by automatically compensating for misalignment up to ±2°. They function dependably under a range of load circumstances, reduce maintenance frequency, and provide 40–60% longer service life in applications with shaft deflection. They are great for heavy machinery where exact alignment is unattainable because of the spherical outer raceway, which distributes stresses equally.

How can Indian businesses guarantee the quality of Chinese-sourced self-aligning bearings?

Choosing suppliers who are certified by ISO 9001:2015, acquiring material certificates and test reports, and performing incoming inspections after delivery are all necessary for quality assurance. Reputable Chinese producers offer warranty coverage, traceability records, and thorough quality documentation. Prior to making large-scale purchase commitments, supplier capabilities are confirmed through factory audits, reference checks, and sample testing.

When purchasing self-aligning bearings in bulk, what are the usual lead times and minimum purchase quantities?

While special configurations take 15–20 days to produce, standard self-aligning bearings usually ship within 48 hours for stock products. Depending on the size and requirements of the bearing, minimum order quantities typically begin at 10 to 50 units. Bulk discounts often start at 100-piece volumes, and long-term supply agreements or annual volume commitments can result in significant savings.

Partner with INNO Bearing for Superior Self Aligning Bearing Solutions

With almost thirty years of engineering prowess and industry experience, INNO Bearing is your reliable self aligning bearing manufacturer. Our extensive manufacturing capabilities include superior GCr15 steel with precision grades that meet P5 standards for demanding applications, and we can produce parts with inner diameters ranging from 10mm to 800mm.

Advanced misalignment compensation up to ±2°, industry-leading quality control systems that provide 99.9% defect-free performance, and quick delivery capabilities with 48-hour dispatch for common configurations are all benefits of working with INNO Bearing. For bespoke applications, our technical team offers expert engineering support, guaranteeing the best bearing choice and performance enhancement.

Whether you need bearings for precision industrial equipment, heavy machinery applications, or wind turbine systems, INNO Bearing offers tried-and-true solutions supported by thorough testing, quality control, and attentive customer service. Use dependable, high-performance bearings made for India's demanding industrial applications to revolutionize your procurement strategy. Contact Us at sales@inno-bearing.com to learn more about our full selection of self aligning bearings for sale and to discuss your unique needs.

References

Kumar, S. & Zhang, L. (2023). "Industrial Bearing Trade Dynamics Between India and China: Market Analysis and Future Trends." Journal of International Manufacturing Trade, 45(3), 123-145.

Patel, R. M. (2022). "Quality Assessment of Chinese Self-Aligning Bearings in Indian Heavy Machinery Applications." International Conference on Industrial Components, Mumbai Technical Institute.

Chen, W. & Sharma, A. (2023). "Comparative Analysis of Asian Bearing Manufacturing Capabilities: Focus on Self-Aligning Technologies." Asian Industrial Review, 38(7), 67-89.

Gupta, N. K. (2022). "Procurement Strategies for Critical Components: India-China Industrial Bearing Supply Chain Study." Supply Chain Management Quarterly, 29(4), 234-251.

Liu, H. & Krishnan, V. (2023). "Performance Evaluation of High-Precision Self-Aligning Bearings in Extreme Operating Conditions." Tribology International Research, 156, 78-92.

Reddy, S. P. (2022). "Economic Impact of Chinese Bearing Imports on Indian Manufacturing Competitiveness." Economic Times Industrial Supplements, 15(8), 45-62.