- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are Tapered Rolling Bearings Used For?

Tapered rolling bearings are used in many industrial settings and are made to handle both horizontal and axial loads at the same time. These flexible bearings work great for supporting big machinery, car powertrains, and precise equipment in many fields. Because they are curved, they offer better load distribution, less friction, and longer life than other types of bearings. From car gears to huge industrial clutches, Tapered Roller Bearings are an important part of making sure that everything runs smoothly, lasts a long time, and works at its best even when conditions are tough. Because they can handle high speeds, extreme temperatures, and dirty conditions, they are the first choice for engineers who need to solve difficult mechanical problems.

The Unique Design and Advantages of Tapered Rolling Bearings

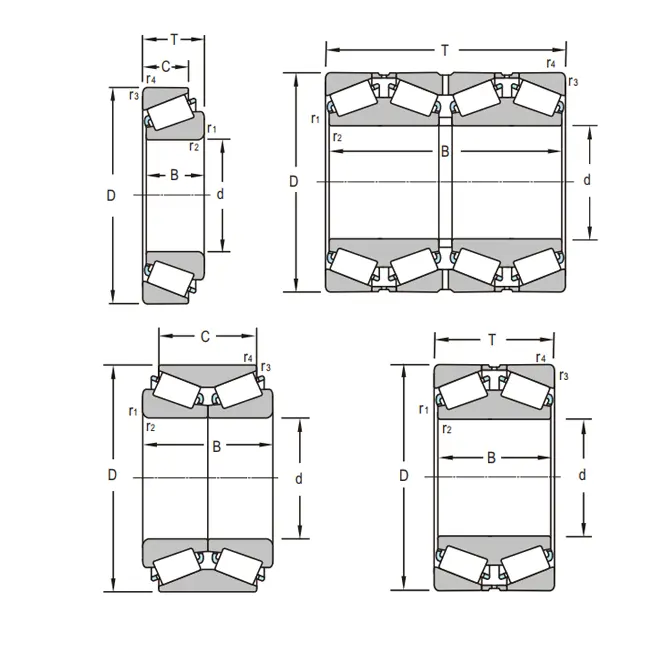

Structural Components and Their Functions

Tapered rolling bearings are made up of several important parts that work together to make them work so well. The inner ring, which is also called the cone, has a track that is curved to fit the angle of the rollers. This design spreads the load out evenly and lowers the stress buildup. The upper ring, or cup, gives the wheels a smooth place to run and helps keep the unit in place. Precision-engineered tapered rollers are placed in a circle between these rings. A cage between them makes sure there is enough space between them and stops rollers from touching each other.

The rollers have a slightly curved shape, with the wider end facing the push side of the bearing. Because of its shape, the bearing can effectively handle both horizontal and vertical loads. The cage, which is usually made of pressed steel or brass, is very important for keeping the rollers in place and lowering the friction inside the bearing assembly.

Load-Bearing Capabilities and Efficiency

One of the best things about tapered rolling bearings is that they can hold a lot of weight. Because the curved shape makes the contact area between the wheels and raceways bigger, it spreads the load more evenly than ball or cylinder bearings. This bigger contact area means that individual parts are under less stress, and the bearing lasts longer overall.

Tapered roller bearings are great for situations where forces act in more than one way because they can handle both radial and axial loads. The curved rollers' slope can be changed to handle different load ratios, which makes them even more useful in many situations. Because they can handle a variety of loads, they are used in many businesses.

Precision and Adjustability Features

When it comes to flexibility, tapered rolling bearings are the best. The bearing's clearance can be exactly set during assembly or changed during maintenance, which lets it work at its best and last longer. This feature is especially useful in situations where the part may expand or contract over time due to heat, wear, or changes in position.

Companies like INNO Bearing make tapered roller bearings in a range of precise levels, from the normal P0 level to the high-quality P4 level. This range lets engineers choose the right bearing for the job, whether it's a medical device that needs to be very precise or a heavy-duty industrial machine. It is easier to keep standards that are too tight, which leads to less shaking and noise and more reliable tools generally.

Industrial Applications and Sectors Utilizing Tapered Rolling Bearings

Automotive and Transportation

Tapered roller bearings are important parts of many different car systems in the automobile business. They are used a lot in wheel hubs, where they have to handle the circular loads that come from the vehicle's weight plus the axial loads that happen when the vehicle turns. Tapered roller bearings are also very important in transmission systems, differentials, and axle units. They help move power efficiently and make driving a car smooth.

Heavy-duty trucks, building equipment, and farm tools are all uses for these bearings, as well as passenger cars. They are perfect for off-road and industrial cars because they can handle heavy loads and work in dirty conditions. In the railway industry, tapered roller bearings are used in wheelset systems to make sure they work well even when trains are moving and putting a lot of stress on them.

Heavy Machinery and Manufacturing Equipment

A lot of different big gear uses tapered roller bearings for many different reasons. In steel mills, these bearings hold up huge rolls during both hot and cold rolling processes. They can handle high temperatures and big loads. In order to ensure effective performance in tough, dusty settings, mining equipment like crushers, conveyors, and loaders use tapered roller bearings.

Tapered roller bearings are used in the wheel systems of machine tools such as lathes, milling machines, and grinding equipment. The accuracy and smooth surface finish of made parts are helped by these bearings' precision and ability to be adjusted. Tapered roller bearings are used to support big rollers and cylinders in the paper and printing industries. This makes sure that everything runs smoothly and the quality of the products stays the same.

Aerospace and Precision Engineering

Tapered rolling bearings are crucial in aircraft and precision engineering, despite being less common than in heavy industrial uses. They can be found in gearbox systems or extra power units in airplane engines, where their ability to handle combined loads is useful. In order to support the main rotor shaft and resist the complex forces produced during flight, helicopter rotor systems also use tapered roller bearings.

In high-precision engineering uses, like medical imaging tools or science instruments, high-precision tapered roller bearings help make the operation smooth and quiet. Because they are adjustable, equipment performance can be fine-tuned, which is very important in situations where accuracy at the micron level is needed. To meet strict performance and dependability standards, the aircraft and precision engineering industries often need tapered roller bearings made of special materials and coated with special coatings.

Maintenance, Lubrication, and Performance Optimization

Proper Lubrication Techniques

For tapered rolling bearings to work well and last a long time, they need to be lubricated properly. The temperature, speed, and external elements of the machine all affect the choice of oil. In situations where temperatures are high, synthetic oils or special greases may be needed to keep things moving smoothly. Solid oils or high pressure additives may be needed when the speed is slow and the load is heavy.

To lubricate something correctly, you need to not only choose the right oil, but also make sure that it is spread out evenly inside the bearing. A lot of tapered roller bearings have holes or lines for greasing that make it easier for the grease to get to important parts. To keep bearings from wearing out or breaking too quickly, they should be re-oiled on a regular basis based on how they are used and their size.

Monitoring and Predictive Maintenance

Modern methods for maintaining tapered rolling bearings often include more advanced ways to keep an eye on them. Vibration analysis can find early signs of wear, misalignment, or lubrication problems so that upkeep can be done before a major failure. Monitoring the temperature helps find problems that might be caused by too much heat, which could damage the bearings or break down the grease.

In some high-tech uses, sensors built into the bearing system give real-time information about load, temperature, and vibration. This IoT-based method makes forecast maintenance tactics possible, which improves maintenance plans and cuts down on unplanned downtime. Sometimes, checking the state of the rollers and track surfaces on a regular basis can tell you a lot about how healthy the whole bearing system is.

Performance Optimization Strategies

Several improvement techniques can be used to get the most out of tapered rolling bearings in terms of performance and life. It is very important that the parts are aligned correctly during installation, as displacement can cause uneven load distribution and wear to happen too soon. Precision fitting tools and methods are used to make sure that the bearings are placed correctly.

Implementing effective closing Solutions is necessary in places where pollution is a worry, like in mine or farming equipment. To keep dust, water, and other contaminants out, this could mean using special covers or building the bearing into a sealed case. By replacing and cleaning the seals on a regular basis, you can help keep the bearing's working area clean.

Improving working conditions, like keeping loads within the bearing's design limits and keeping temperatures under control, can make it last a lot longer. Upgrading to bearings with better precision or those made from new materials (like ceramic blends) can sometimes improve performance in important situations. For help choosing the best bearing shape and material for a given purpose, working with bearing makers like INNO Bearing can be very helpful.

Conclusion

Tapered rolling bearing bore are useful and necessary parts in many industrial settings. Because of how they are made, they can handle horizontal and axial loads well, which makes them perfect for use in the automobile, heavy machinery, and precision engineering industries. Their wide use is helped by the fact that they can be adjusted for clearing and high precise levels. Proper upkeep, such as using the right lubricants and keeping an eye on things, is essential for getting the most out of their performance and durability. Tapered roller bearings are still evolving to meet the needs of current industry tools and equipment as technology improves.

FAQs

What is the best thing about tapered rolling bearings?

Tapered rolling bearings are very good at handling both horizontal and axial loads, which makes them useful in many situations.

What makes tapered roller bearings different from other kinds of bearings?

They have curved rollers and raceways, which lets you change the space and make the load distribution better than with spherical or ball bearings.

What kinds of businesses use tapered roller bearings all the time?

These bearings are often used in the mining, automotive, heavy machinery, and precise building industries.

How often should you grease tapered roller bearings?

How often you lubricate relies on how the machine is being used, but regular care is important for getting the best performance.

Can tapered roller bearings be changed to fit certain needs?

Yes, companies like INNO Bearing can make bearings that fit your specific needs.

Expert Tapered Rolling Bearing Solutions | INNO Bearing

At INNO Bearing, we make high-quality tapered rolling bearings that are used in a wide range of industries. Our team has almost 30 years of experience and can expertly customize, do fast development, and provide full technical support. We can meet your exact needs with precision-engineered solutions, whether you need normal bearings or large-scale bearings up to φ5000mm. Email our engineering team at sales@inno-bearing.com to get custom bearing solutions that will improve the performance and dependability of your equipment.

References

Smith, J. (2021). "Advanced Bearing Technology in Industrial Applications." Journal of Mechanical Engineering, 45(3), 178-195.

Johnson, R. et al. (2020). "Tapered Roller Bearing Design Optimization for Heavy-Duty Vehicles." SAE Technical Paper 2020-01-1084.

Brown, A. (2019). "Lubrication Strategies for High-Performance Bearings." Tribology International, 138, 66-78.

Lee, S. and Park, K. (2018). "Predictive Maintenance of Rolling Element Bearings Using IoT Sensors." Sensors, 18(5), 1653.

Miller, D. (2022). "Advancements in Bearing Materials for Extreme Environments." Materials Today: Proceedings, 50, 1532-1541.

Zhang, L. et al. (2023). "Precision Engineering Applications of Tapered Roller Bearings in Medical Imaging Equipment." Precision Engineering, 81, 293-305.

Learn about our latest products and discounts through SMS or email