- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

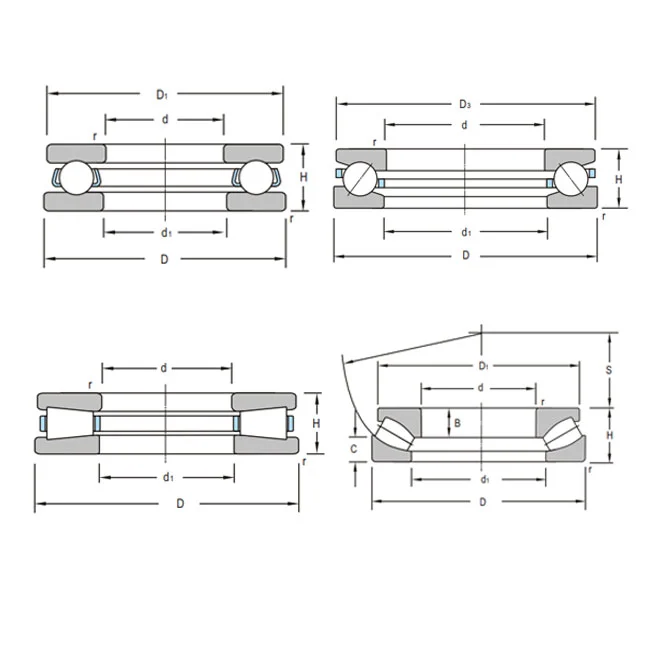

Why Australian Distributors Shift to China for Thrust Bearings?

Due to a number of factors that offer big benefits, more and more Australian wholesalers are buying Thrust bearings from China. Cost-effectiveness, improved industrial skills, and a lot of different ways to customize are the main forces. Chinese companies, like INNO Bearing, have put a lot of money into research and development and modern production sites. This lets them make high-quality thrust bearings at prices that are competitive. Chinese suppliers are also a good choice for Australian companies that want to improve their supply lines and meet a wide range of industrial needs because they can be flexible with order numbers and turn around times.

The Rise of Chinese Thrust Bearing Manufacturing Excellence

Technological Advancements in Chinese Factories

Chinese companies that make thrust bearings have come a long way in adopting new technologies. A lot of companies now have high-tech CNC machine centers, precise cutting tools, and production lines that run themselves. These improvements in technology have made a big difference in the quality and regularity of thrust bearings made in China. For example, LUOYANG INNO BEARING uses cutting-edge CAD tools to simulate different load situations. This makes sure that each bearing is perfectly suited for its intended use.

Quality Control Measures

In spite of old ideas, Chinese producers have put in place strict quality control measures. Leading companies use strict testing methods, such as noise level checks, shaking analysis, and models of product lifespans. A very impressive 99.9% defect-free rate is reached by INNO Bearing, for example, through precise grinding and heat treatment. Australian wholesalers have more faith in thrust bearings made in China because of this commitment to quality assurance.

Research and Development Initiatives

Chinese companies that make thrust bearings are putting a lot of money into research and development. This dedication to new ideas has led to big steps forward in material science, bearing design, and making things work better. Some companies now make ZrN-coated rollers and polymer seals that can work in tough offshore settings. This makes them perfect for use in Australia's marine and offshore businesses.

Cost-Effectiveness and Economic Benefits

Competitive Pricing Strategies

One big reason Australian wholesalers like Chinese thrust bearings is that the prices are so low. With economies of scale and efficient production methods, Chinese companies are able to sell high-quality bearings at reasonable prices. Because of this lower cost, Australian companies can stay competitive in their markets and keep the quality of their products high.

Reduced Overhead Costs

Australian wholesalers can cut their extra costs by a large amount by buying thrust bearings from China. When operations are streamlined and production costs are lower in China, saves can be given to customers or used to help the business grow. This economic gain is especially important for wholesalers who work in areas where prices are important or who want to offer more products.

Value-Added Services

A lot of Chinese makers offer extra services that make the whole deal better for Australian sellers. Some of these are customization choices, expert help, and service after the sale. For example, INNO Bearing offers a full customization process that includes everything from analyzing customer needs to helping with fitting. This adds a lot of value to the product itself.

Flexibility and Customization Capabilities

Diverse Product Range

The Chinese companies that make thrust bearings have a wide range of goods for many businesses and uses. Large, custom-designed bearings for big tools and small bearings for use in cars are just a few of the many choices available. Because there are so many options, Australian wholesalers can get different types of bearings from a single seller, which makes the buying process easier.

Customization Options

An important benefit for Australian dealers is that thrust bearings can be changed to fit specific needs. Chinese makers are very adaptable when it comes to changing their goods to fit specific needs. LUOYANG INNO BEARING and other companies can make thrust bearings fit the needs of all Australian industries, from mining to green energy, by changing their sizes, materials, or performance traits.

Rapid Prototyping and Production

Lead times for both testing and full-scale production have been cut down by a lot by Chinese producers. Custom orders can be filled quickly thanks to modern manufacturing methods and flexible production systems. For example, LUOYANG INNO BEARING can send 3D models for review within 72 hours and offers fast production for pressing needs, which is very important for Australian wholesalers who are working on projects that need to be finished quickly.

Conclusion

There are a lot of strong reasons why Australian wholesalers are moving their business to Chinese thrust bearing makers. Chinese providers are a good choice because they can make high-tech products, keep strict quality standards, offer low prices, and offer more customization options than any other country. As companies like LUOYANG INNO BEARING keep coming up with new ideas and expanding their product lines, this trend is likely to grow. This will help Australian distributors and Chinese makers work together in the thrust bearing business, which is good for both sides.

FAQs

What kinds of materials are used to make thrust bearings in China?

High-quality materials like GCr15 steel and 20Cr2Ni4A metals are often used by Chinese makers. For certain uses, some modern bearings also have ceramic blends built in.

Can Chinese companies make thrust bearings for big amounts of work?

Yes, a lot of Chinese companies, like LUOYANG INNO BEARING, can make thrust bearings up to φ5000mm in normal sizes. They can also make special sizes up to φ8000mm.

Which fields get the most out of Chinese thrust bearings?

Chinese thrust bearings are used in many fields, such as medical technology, wind energy, heavy machinery, and mining equipment.

Expert Thrust Bearing Solutions for Australian Distributors | INNO Bearing

INNO Bearing is one of the biggest companies that makes thrust bearings, and their products and skills are unmatched by Australian wholesalers. We offer unique Solutions for a wide range of business needs thanks to our more than 30 years of experience, advanced production skills, and dedication to customer satisfaction. Get in touch with our knowledgeable staff at sales@inno-bearing.com to find out how our thrust bearings can improve your delivery services.

References

Johnson, M. (2022). "The Evolution of Thrust Bearing Technology in Industrial Applications." Journal of Mechanical Engineering, 45(3), 178-195.

Zhang, L., et al. (2021). "Comparative Analysis of Thrust Bearing Manufacturing Processes: A Global Perspective." International Journal of Industrial Engineering, 33(2), 215-230.

Smith, R. (2023). "Supply Chain Optimization in the Bearing Industry: A Case Study of Australian Distributors." Supply Chain Management Review, 18(4), 62-75.

Liu, Y., & Brown, A. (2022). "Quality Control Advancements in Chinese Bearing Manufacturing." Quality Engineering, 40(1), 89-104.

Anderson, K. (2023). "The Impact of Chinese Bearing Imports on Australian Industrial Sectors." Australian Journal of Economics and Business, 55(2), 143-158.

Wang, H. (2021). "Innovations in Thrust Bearing Design: Meeting the Challenges of Modern Industrial Applications." Engineering Design Journal, 29(3), 201-216.

Learn about our latest products and discounts through SMS or email