A thrust ball bearing is a specific type of rolling element bearing that is built to handle axial (thrust) loads when things that turn are used. Radial bearings hold loads at right angles to the shaft. These other bearings, on the other hand, are made with exact steel balls placed between hardened raceways to handle forces parallel to the shaft axis. Thrust ball bearings work well in situations where low friction coefficients and dependable performance are needed with axial loads from light to medium level. They come in single-row or double-row configurations and are and are used in a wide range of fields, from wind energy to making heavy machinery.

Understanding Thrust Ball Bearings: Definition and Design Features

Thrust ball bearings use a complex system to work. Steel balls spin between two or more hardened steel washers, which spreads out the axial forces throughout the bearing assembly. The basic design includes a number of important parts that work together to make sure it works well.

Core Parts and How to Put It Together

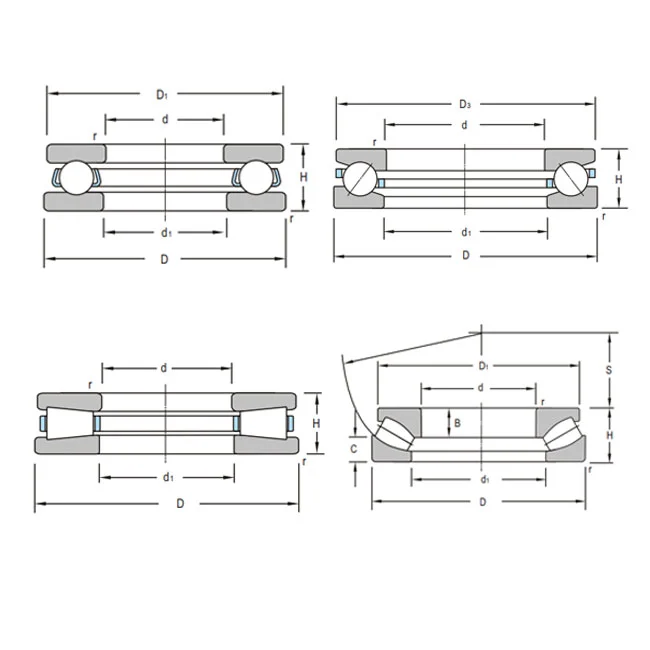

Shaft washers, housing washers, rolling elements (steel balls), and a cage system that keeps the balls spaced correctly make up the bearing assembly. In unidirectional setups, there is a shaft washer, a housing washer, and single-row steel balls. With bidirectional variants, there is an intermediate washer between the double shaft washers with steel balls in two rows. This lets the bearing handle axial loads coming from either direction.

The way materials are made has a big impact on bearing performance. Shaft, housing, and intermediate washers are made from high-quality steel alloys like GCr15, GCr15SIMN, and 20Cr2Ni4A, which are very hard and resistant to wear. The rolling parts are made of GCr15 or GCr15SIMN steel, and the cages are made of brass or stamped steel to keep friction low and the structure intact even when a lot of stress is put on them.

Tolerance Standards and Precision Engineering

With modern manufacturing techniques, thrust ball bearings are able to get amazing precision. Standard models can meet the P0 and P6 levels of accuracy, but P5 levels of accuracy are needed for precision applications. The sizes fit a lot of different industrial needs. The inner diameters are anywhere from 10 mm to 300 mm, the outer diameters are from 30 mm to 400 mm, and the heights are from 8 mm to 50 mm. If you need even bigger sizes, custom applications can help. For example, specialised manufacturers make products with outer diameters of up to 5000 mm for very heavy-duty uses in the industrial sector.

Types and Advantages of Thrust Ball Bearings

Ball Thrust bearings are useful in a lot of different situations because they are made of different materials and come in different shapes, each one perfect for a certain job. Engineers can choose the best bearing type for their needs when they know about these differences.

One-Way and Two-Way Setups

Single-direction thrust ball bearings can only handle axial loads that go in one direction. They are a good fit for situations where the load pattern doesn't change because of their simple design. These bearings are best used in spindles for machine tools, water pumps, and small motors where space and weight matter most. Versions with two directions can handle axial loads that move in either direction. This means they can be used when the direction of the load changes while the cycle is going on.

Benefits of the Materials Used

Thrust ball bearings have benefits that make them impossible to replace in today's industry. These are the main benefits that make these parts unique:

- Low Friction Coefficient: The rolling contact between balls and raceways minimises the energy loss and heat generation. This makes the system more efficient and prolongs its working lifetime.

- Space-Saving Design: This type of construction uses only a small amount of space, so you can build in tight areas without hurting the structure's strength or performance.

- High Axial Load Support: These bearings can handle large axial loads and keep rotating smoothly because the ball-to-raceway contact patterns are made so that the forces are spread out.

- Temperature Stability: The device can work in hot places if it is made with a special material and is heated in the right way. Some specialised versions can even work at temperatures over 150°C.

Thrust ball bearings are a cost-effective option for difficult industrial uses because they make machines more efficient, lower the need for upkeep, and extend the service life of the equipment. All of these benefits make thrust ball bearings a cost-effective choice for tough industrial applications.

Common Problems and Maintenance Tips for Thrust Ball Bearings

Care greatly impacts thrust ball bearing performance and lifespan. Knowing what usually goes wrong and fixing it helps equipment and operations run smoothly.

How to Avoid Common Failure Reasons

Dirt is a leading cause of premature bearing failure. Particles in the bearing assembly damage raceways and rolling elements. Friction and noise increase, causing assembly failure. Good sealing systems and clean work areas reduce contamination.

Lubricating incorrectly accelerates wear and overheating. The machine's use, weight, and environmental impact should determine when maintenance teams lubricate. Overlubrication heats things up and breaks seals.

Quality Control and Inspection

Make sure the steel balls are far enough apart, the shaft and housing washers are flat, and the rolling elements are arranged correctly. Regularly checking these parameters detects issues before they affect system performance. Bearing wear can be detected by vibration and temperature monitoring. You can fix problems before they worsen.

Applications and Performance Considerations in Industry

Thrust ball bearings serve critical functions across diverse industrial sectors, each presenting unique operational challenges and performance requirements. Understanding application-specific demands ensures optimal bearing selection and system integration.

Wind Energy and Heavy Machinery Applications

Thrust ball bearings in wind turbines control substantial axial loads in pitch control mechanisms and yaw systems. These uses require a high level of resistance to fatigue and a long service life even when load conditions change. The bearings must be able to handle changes in temperature, exposure to moisture, and vibration from wind.

Bearings that can handle very harsh conditions are needed for mining and metallurgy when heavy machines are used. Rolling mill gearboxes use specialised thrust ball bearings that are designed to handle axial loads of up to 200 kN and keep their accuracy even when in use all the time. Ceramic hybrid ball technology and heat-resistant lubrication systems make smelting furnace conveyors more reliable at high temperatures.

Aerospace and Defence Needs

Ultra-precise bearings are needed for radar systems, satellite tracking devices, and big platforms that rotate in aerospace applications. These bearings must keep a noise level below 35dB while also being very accurate and reliable. Specialised engineering help makes sure that strict aerospace standards and certification needs are met.

Procurement and Sourcing Strategies for Thrust Ball Bearings

When making purchasing decisions, people who know what they're doing take more than just price into account. They also think about how quickly they need the product, how they will help customers in the future, and how they will make sure that the product is high quality. Knowing how the market works and what suppliers can do helps people make smart buying choices that lower the overall cost of ownership.

Quality Assurance and Supplier Evaluation

The top bearing suppliers in the world offer a wide range of standard and custom-bearing options. Quality certifications, technical support resources, supply chain reliability, and manufacturing capabilities are all,Evaluation criteria that should be taken into account. Suppliers who do a lot of different tests, like lifespan simulation, vibration analysis, and thermal cycling, show that they are committed to high quality.

Quality assurance includes the ability to trace materials back to their source, precision grinding, and final inspection. It goes beyond the first steps of manufacturing. Advanced Suppliers get defect rates under 0.1% by using strict quality control and continuous improvement programmes.

INNO Bearing: Your Trusted Partner for High-Performance Solutions

Luoyang INNO Bearing Co., Ltd. is a leader in bearing manufacturing. They have almost 30 years of experience in the field and use new technology while always focussing on quality. Because of our unique knowledge in large and non-standard bearings, we are the most preferred thrust ball bearing supplier for tough industrial applications.

High-Tech Manufacturing Skills

Our cutting-edge facilities combine R&D, precision manufacturing, and full testing capabilities all in one place. We are great at making custom bearings with outer diameters up to 5000 mm, which meet needs that standard bearings can't. Our rapid prototyping can make 3D models and material suggestions within 72 hours. This speeds up project timelines and lowers development costs.

Quality assurance is still very important to how we do business. All bearings are put through a lot of tests that include vibration analysis, thermal cycling, and lifespan simulation. To make sure that the alloys are consistent, material inspections use spectrometer technology, and precision grinding makes sure that the raceways are within 0.001mm. These hard processes make sure that only 0.1% of goods are defective, from the materials to the final packaging.

Our global supply chain advantage includes regional warehouses in Europe, Asia, and North America, which makes it possible to deliver standard models in 48 hours and give priority to emergency replacement orders. Customers can keep an eye on orders from the factory to the facility with open tracking systems that make sure the whole procurement process can be seen.

Conclusion

Thrust ball bearings are very important parts of modern industrial machines. They are made with advanced materials and precise designs that make sure they can handle axial loads. Understanding their structure, types, maintenance requirements, and how they are used makes it possible to make smart buying decisions that improve equipment performance and operational efficiency. Choosing the right bearings affects how reliable the system is, how much it costs to maintain, and how productive it is overall. As the needs of industry change in the direction of higher performance and reliability standards, working with manufacturers who have a lot of experience becomes necessary to keep your business running smoothly and ahead of the competition in tough market conditions.

FAQs

How are thrust ball and thrust roller bearings different?

Steel balls make thrust ball bearings ideal for moderate axial load applications at high speeds. Thrust roller bearings use cylindrical rollers and have higher load capacity but lower speeds. Roller bearings handle heavier loads but generate more heat and noise than ball bearings.

Can thrust ball bearings transfer radial loads?

Radial forces are not recommended for thrust ball bearings, which are designed for axial loads. Radial loads cause premature failure, wear, and performance issues. Combination bearing Solutions or load-specific bearing assemblies should support axial and radial loads.

Thrust ball bearing maintenance frequency?

Operating conditions, load factors, and environment affect maintenance frequency. Lubricate and inspect every 3-6 months under normal conditions. Monthly maintenance may be needed in high-temperature, high-load, or contaminated environments. Maintenance scheduling can be optimised using vibration and temperature data.

Partner with INNO Bearing for Superior Thrust Ball Bearing Solutions

For the most difficult industrial uses, INNO Bearing's precisely designed thrust ball bearing solutions will make your business run more smoothly. Our wide range of products includes both standard models and custom engineering options. This guarantees that you get the best performance across a range of operational needs. Our technical know-how and great manufacturing can give you reliable solutions that go beyond industry standards, whether you need normal setups or custom designs for extreme conditions.

Experience the INNO Bearing advantage through our commitment to quality, innovation, and customer success. Our dedicated engineering team provides comprehensive support from initial consultation through installation and ongoing maintenance, ensuring your bearing solutions deliver maximum value and operational reliability. Ready to enhance your machinery performance with industry-leading thrust ball bearing technology? Contact Us at sales@inno-bearing.com to discuss your specific requirements, request detailed technical specifications, or explore our extensive catalog of precision bearing solutions.

References

Harris, T.A. & Kotzalas, M.N. "Essential Concepts of Bearing Technology: Rolling Bearing Analysis" (5th Edition). Taylor & Francis Engineering Publications, 2006.

Hamrock, B.J., Schmid, S.R. & Jacobson, B.O. "Fundamentals of Fluid Film Lubrication: Thrust Bearing Applications" McGraw-Hill Mechanical Engineering Series, 2004.

ISO 104:2015 "Rolling bearings - Thrust ball bearings - Dimensional specifications and tolerances" International Organization for Standardization Technical Committee, 2015.

SKF Group Technical Manual "Thrust Ball Bearing Design and Application Guidelines for Industrial Machinery" SKF Engineering & Research Center, 2018.

American Society of Mechanical Engineers "ASME Standards for Thrust Bearing Performance in Heavy Industrial Applications" ASME Press Engineering Standards, 2019.

National Institute of Standards and Technology "Bearing Performance Analysis in High-Temperature Industrial Environments" NIST Special Publication 800-Series, 2020.