When industrial equipment is under a lot of stress, the bearing technology chosen is very important for the operation to go well. When the performance standards are hard to meet in settings with heavy loads, conical roller bearings really shine where other bearing types don't. These specialized parts have tapered rollers that work better at spreading radial and axial forces than standard parts. This makes them very important for wind turbine gearboxes, mining crushers, and port machinery. The tapered shape of these rollers gives them better load capacity. They also reduce friction and wear, which greatly extends the lifetime of the equipment that uses them. Procurement professionals who know the technical benefits of these bearing systems and how to use them correctly can make good choices that improve the reliability of their operations and lower the total cost of owning them in difficult industrial settings.

Understanding Conical Roller Bearings and Their Role in Heavy Load Applications

Because of how they are designed, tapered rollers are the most popular choice for heavy-duty industrial applications. The conical shape makes the best contact patterns between raceways and rolling elements. It also spreads the weight over a larger area, unlike cylindrical or spherical shapes. This basic benefit stands out most clearly when it is used in combined loading scenarios that are common in wind energy systems and heavy machinery.

For the best performance, structural design must be done perfectly.

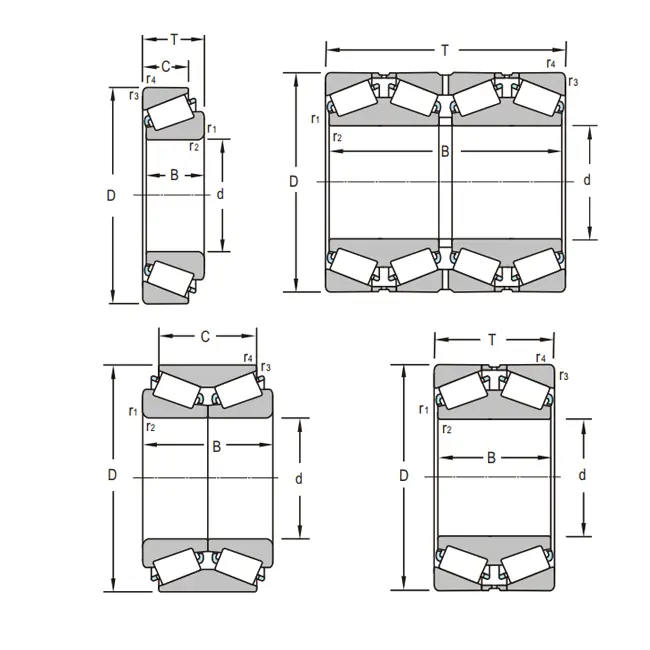

Today's conical roller bearings use advanced structures that make them better at handling heavy loads. The inner ring features a tapered raceway precision-machined to exacting tolerances, while the outer ring configuration varies between separable single-row designs and fixed double-row assemblies depending on application requirements. When stamped steel or brass are used to make advanced cage systems, they keep the rollers spaced properly and stop skidding even when a lot of weight is put on them. These bearings come in both open and sealed types. They can handle a range of conditions while still working properly.

Making Standards for Durability with Material Innovation

Choosing the right materials sets high-performance Tapered Roller Bearings apart from other standard industrial parts. Inner rings, outer rings, and rollers are made of different steel alloys, like GCr15, GCr15SiMn, and 20Cr2Ni4A. Each one is designed for a particular set of environmental conditions and load types. These advanced metallurgies are used in very exact heating processes that make them more resistant to fatigue and better at keeping their shape. As a result, the bearing parts can handle dynamic loads over 3,500 kN while keeping the exact measurements needed for smooth operation in important cases.

Key Benefits of Using Conical Roller Bearings for Heavy-Duty Applications

The tapered roller technology works better, which gives procurement professionals operational benefits they can measure by seeing that maintenance costs and equipment lifecycles are lowered. These benefits are much clearer in applications where being offline for a long time costs a lot of money, like in mining operations and offshore wind installations.

Increased Load Capacity and Longer Lifespan for Operations

Comparative testing shows that conical roller bearings are always better than cylindrical, spherical, and needle roller bearings when there is a lot of weight. The tapered shape spreads out the stress better, lowering the high contact pressures that usually cause conventional designs to fail too soon. Thanks to better load distribution, these bearings can handle radial loads up to 40% higher than Cylindrical roller bearings of the same size. They can also handle very large axial forces at the same time. In real-world uses of steel mill equipment, service life has been over 60% better with new bearing technologies compared to older ones.

Ability to Work in Many Difficult Areas of the Economy

These bearing systems have strong performance traits that make them useful in a number of heavy-duty industries where dependability is key. When wind turbine manufacturers need to use the main shaft, they depend on large tapered roller bearings with big diameters. The weight of the rotor and the wind create tough working conditions. These parts are used in crusher assemblies and conveyor systems for mining operations, where rough conditions and heavy loads make high durability necessary. Construction equipment uses tapered roller systems that are designed correctly so that they can handle being out of line and resist damage from heavy objects.

Advanced Surface and Coating Treatments

Newer surface engineering methods have pushed the performance of conical roller bearings beyond the old limits. In marine environments, specialized anti-corrosion coatings protect the surface. In places that are hard to get to, advanced lubrication systems make relubrication intervals longer. These new ideas help get the best overall cost by lowering the need for maintenance and improving operational availability in critical applications.

Comparative Analysis: Conical Roller Bearings vs Other Bearing Types

Engineering teams that are looking into bearing Solutions for heavy-load applications need to know the different kinds of performance that makes each bearing technology unique. This study focuses on performance metrics that can be measured and that directly affect procurement decisions and operational outcomes.

Built-In Benefits Compared to Other Technological Options

The basic design of conical roller bearings is different from other types of bearings, which causes them to perform differently in heavy-load situations. Spherical roller bearings can self-align, but their point contact geometry means they can't hold as much weight. Cylindrical roller bearings work well when the load is purely radial, but they can't handle the combined loading that is common in heavy machinery. Needle bearings are space-saving, but they don't have the durability needed for long service times in harsh environments. The line contact made by tapered rollers spreads the load evenly and keeps the structure together for use in heavy-duty applications.

Misalignment Tolerance and Load Capacity

Quantitative testing shows that conical roller systems with the right design can handle more weight. For heavy-duty versions, dynamic load ratings can exceed 2,000 kN in small sizes. These versions can handle some misalignment, which is useful for installation in the real world. Being able to handle both radial and axial loads at the same time means that complicated bearing setups aren't needed. This makes machinery design easier and bearing procurement costs much more affordable. This feature is especially useful for wind turbines, where load directions change and make it hard for normal bearing solutions to work.

Selection Criteria for the Best Performance

It is important to carefully consider operational parameters and lifecycle costs when choosing between light-duty and heavy-duty versions. Heavy-duty designs include larger rolling parts and better cage systems that make them more resistant to wear in applications with high loads. But, to get these benefits, the size and weight requirements go up, which could affect how machines are designed. A range of precision grades from the common P0/P6 levels to very precise P4/P5 specs meet different needs and allow for cost savings through the matching of specs.

Procurement Considerations: How to Choose and Buy Conical Roller Bearings

If you want to successfully buy conical roller bearings, you need to carefully consider the technical requirements, what the supplier is able to do, and the total cost. This all-encompassing method guarantees the best bearing choice. It also lowers the costs and risks of procurement and the bearing's lifetime.

Important Factors for Technical Evaluation

Load analysis is the basis for choosing the right bearing. It needs to be done correctly by measuring radial and axial force components in all conditions. Speed limits must take into account both continuous and intermittent operation profiles because tapered roller bearings show performance characteristics that depend on speed. Environmental factors such as very high or low temperatures, pollution, and easy access to lubrication have a big effect on how bearings are chosen and how long they are expected to last. Following industry standards like ISO 281 for load ratings and DNV GL certification for wind energy applications makes sure that the rules are followed and the performance is reliable.

Quality Assurance and Supplier Evaluation

Looking at a supplier's manufacturing capabilities, quality systems, and technical support resources can help you decide if they are a good fit for your business. Top manufacturers keep large testing facilities that can confirm bearing performance under conditions that mimic real life. ISO 9001 and IATF 16949 are examples of quality certifications that guarantee that products are made in the same way every time. Also, having certifications in wind energy or aerospace shows that you have a lot of knowledge in those fields. Being able to help with things like application engineering and failure analysis makes the procurement relationship much more valuable.

Getting the Best Prices and Managing the Supply Chain

Total cost optimization looks beyond the price of the bearing itself and includes the costs of installing it, maintaining it, and replacing it over its lifetime. Buying in bulk can save a lot of money, but it also costs money to store the extra items and there is a risk that the technology will become outdated. Managing lead time becomes very important when bearing failure means expensive downtime. This makes the ability of the supplier to deliver on time and respond to emergencies essential for making a judgment.

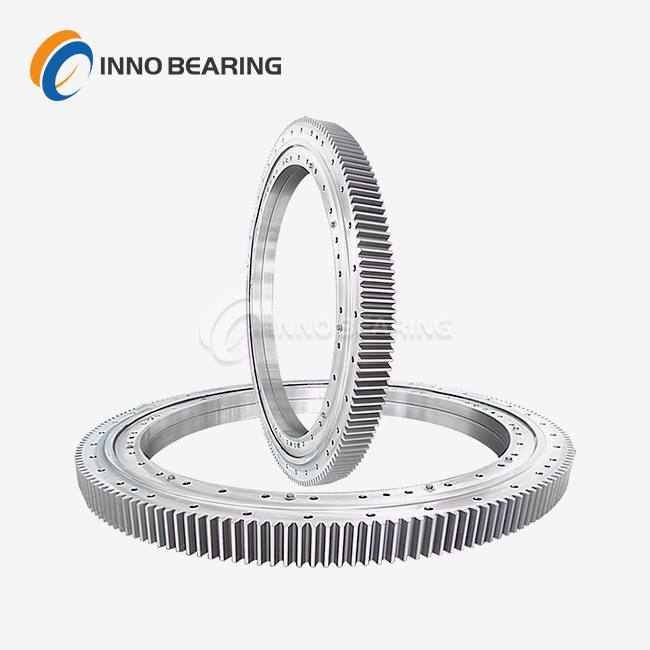

INNO Bearing: Premium Solutions for Heavy Load Applications

After almost 30 years of great engineering and new ideas in manufacturing, Luoyang INNO Bearing Co., Ltd. has become a top maker of specialized tapered roller bearings. Our promise to quality and customer happiness leads to constant progress in bearing technology and how services are delivered.

A wide range of products and the ability to customize them

Our wide range of products includes both single-row and double-row setups that can handle combined loads in a variety of settings. The factory can make custom sizes up to φ5000mm, which makes it possible to find ways to install the biggest industrial machines. The inner diameter can be anywhere from 10 mm to 1,000 mm, which works for everything from exact machine tools to very large mining equipment. Also, the precision grades range from the standard P0/P6 to the ultra-precise P4/P5 levels, which meet the most strict performance standards. Advanced sealing and special materials make sure that the best performance is achieved in difficult environmental conditions.

Technical Greatness and Quality Assurance

All of the bearings made in our shops are fully tested for quality. This includes checking the materials, the dimensions, and how well they work. Through strict Process Control and efforts to constantly improve, our quality systems keep 99.9% of defects away from important performance measures. Vibration analysis according to ISO 15242 standards and long-lasting simulations that show how well bearings work in faster conditions are part of advanced testing. This promise to quality makes sure that important applications work reliably, where failure is not an option.

Global Help and Service Quality

Our global service network gives customers around the world quick delivery and responsive technical support. Emergency replacement programs get critical bearings to regional centers within 72 hours, which cuts down on downtime in emergencies. Application engineering help, installation advice, and failure analysis are all parts of technical support that help customers get the most out of their bearings and stop failures from happening too soon. ISO 9001 certification, installation guides, and performance specs are all parts of complete documentation that helps customers get the quality they want and follow the rules.

Conclusion

When performance can't be compromised in heavy-duty industrial applications, conical roller bearings are the best choice because they cannThey can handle more weight and are more dependable. Their special tapered shape makes it easy to handle both radial and axial loads. They are also very strong, so they can be used in tough conditions for a long time before it needs to be replaced. When procurement experts know about these technical benefits, they can make good decisions that help with the quality of the equipment they buy.tThe right bearings are chosen by looking closely at technical needs, what suppliers can do, and lifecycle issues. This helps projects run smoothly and keeps total ownership costs down.nto help with operational excellence. Tapered roller bearings are crucial for applications with heavy loads because they have been proven to work well and meet the higher performance standards of industrial equipment.

FAQs

Why are conical roller bearings better for heavy loads than other kinds of bearings?

Because of their tapered shape, conical roller bearings spread the weight evenly over larger contact areas. This makes them better than cylindrical or spherical bearings at handling both radial and axial loads at the same time. This design lowers the amount of stress in one place and extends the service life in heavy-duty applications by up to 60% compared to standard bearing technologies.

How do I find the right size and specification for my application of heavy equipment?

To choose the right bearing, you need to carefully consider the load conditions, how fast it will operate, the environment, and how much space you have. We suggest that you talk to application engineers with a lot of experience. They can look at your needs and suggest the best ways to set up your bearings. To be sure that performance is reliable, there must be a consideration of load analysis, speed limitations, and environmental compatibility.

What maintenance practices keep conical roller bearings working well when there are heavy loads?

A good maintenance program is based on regularly checking the vibration, temperature, and lubrication of machinery. Following the right steps and making sure everything is lined up correctly prevent early damage, and controlling contamination greatly extends bearing life. We suggest setting baseline performance metrics when you first install something so that you can keep an eye on changes over time and use predictive maintenance strategies.

Partner with INNO Bearing for Your Heavy Load Solutions

When it comes to reliable conical roller bearings, you can trust INNO Bearing's proven knowledge and great work. Our engineering team is ready to look at your specific application needs and suggest the best ways to set up the bearings so that performance is maximized and costs are minimized. Our high-tech manufacturing and quality control systems make sure that even the most important jobs are always done right, whether you need standard sizes or custom ones up to φ5000 mm. Our competitive volume pricing, quick delivery, and extensive technical support are all great resources to use. To talk about your project's details and get a quote from a reliable conical roller bearing manufacturer, email sales@inno-bearing.com.

References

1. Harris, T.A. and Kotzalas, M.N. "Advanced Concepts of Bearing Technology: Rolling Bearing Analysis." 5th Edition, Taylor & Francis, 2020.

2. International Organization for Standardization. "ISO 281:2007 Rolling Bearings - Dynamic Load Ratings and Rating Life." Geneva: ISO Press, 2007.

3. Palmgren, A. "Ball and Roller Bearing Engineering: Fundamentals of Bearing Performance and Design." Industrial Press, 2019.

4. Stachowiak, G.W. and Batchelor, A.W. "Engineering Tribology: Friction, Lubrication and Bearing Design." 4th Edition, Butterworth-Heinemann, 2021.

5. Williams, J.A. "Engineering Tribology: Surface Technology and Materials Science Applications." Cambridge University Press, 2018.

6. Budinski, K.G. "Surface Engineering for Wear Resistance: Industrial Bearing Applications and Heavy Load Performance." Prentice Hall, 2020.