Mexico's car making industry depends on specialized suppliers and distributors across North America to get high-quality double angular contact bearings for their factories. Industrial bearing distributors in big Mexican towns like Guadalajara, Monterrey, and Mexico City are where these important parts are mostly bought. Many manufacturers also deal directly with global bearing producers. The procurement landscape has local authorized dealers for foreign brands as well as direct import channels from specialized makers who know how to meet the tough needs of car assembly operations.

Understanding Double Angular Contact Bearings in Automotive Applications

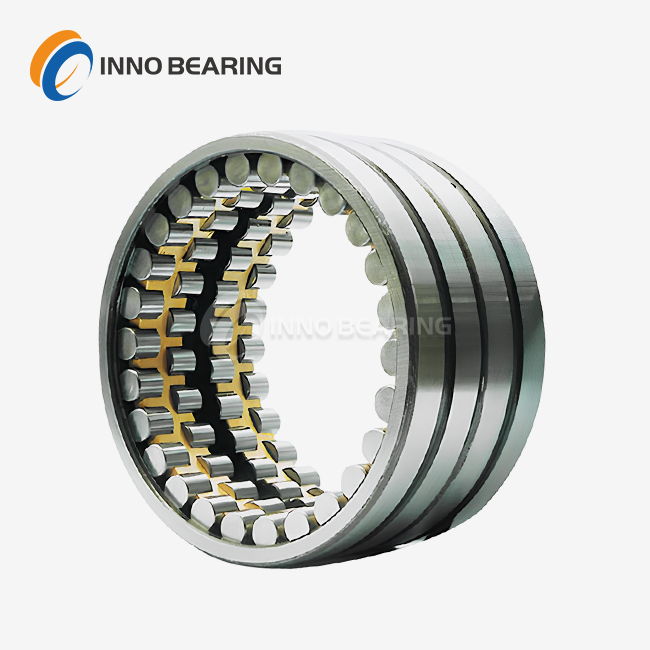

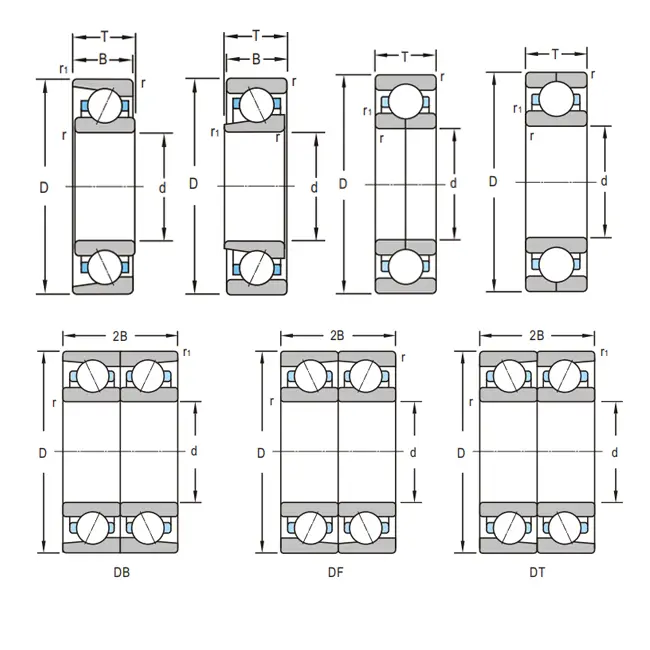

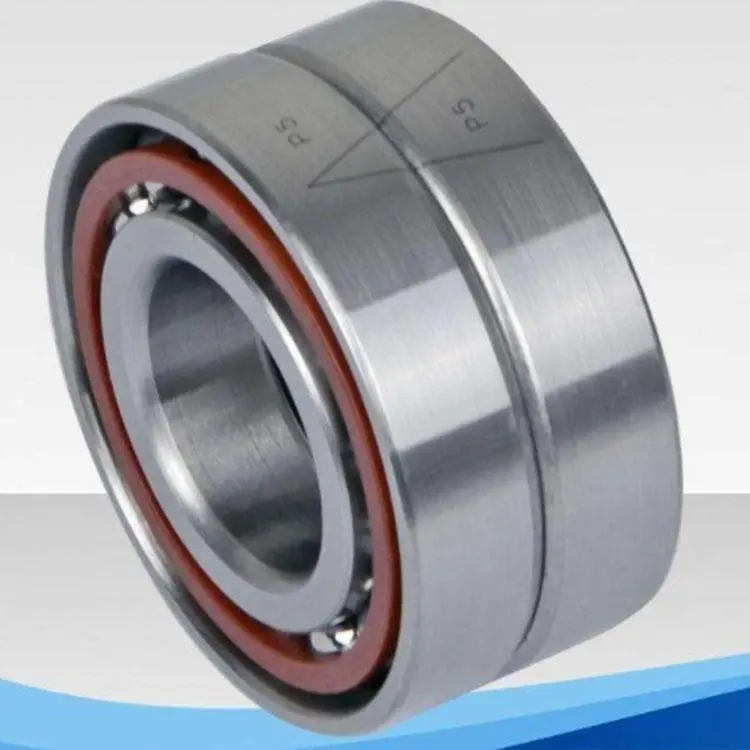

Double angular contact bearings are a complex engineering solution made to deal with the difficult loading conditions that can be found in car manufacturing equipment. These bearings have a special design with an inner and outer ring that each have symmetrical raceways with double angled contacts. They also have two rows of steel balls and cages made of either stamped steel or brass. In this setup, the bearing can still accurately handle pressure from both directions even when the system is moving very quickly.

These bearings' small design makes them especially useful in automotive uses where space is limited. They meet the different needs of machinery in car plants with inner diameters from 20 to 400 mm, outer diameters from 47 to 600 mm, and widths from 20 to 150 mm. For both rings and rolling elements, GCr15 or GCr15SIMN are common building materials that make sure the parts are tough enough to keep working in difficult automotive settings.

These double-row setups provide better load capacity and steadiness than single angular contact or standard ball bearings. They are essential to automobile transmission systems, machine tool feed shafts, and the exact tools that are usually used in current car plants because they can handle axial loads from both directions and large radial loads.

Key Factors to Consider When Procuring Double Angular Contact Bearings in Mexico

Getting Angular contact ball bearings for Mexico's auto industry is only possible if you pay close attention to a few important things that affect how well and how cheaply the business can run. Technical specifications are the most important part of any procurement choice. Load ratings, speed capabilities, and precision grades must be carefully compared to the needs of the specific application.

Depending on the needs of the application, the accuracy standards run from the normal P0 grade to more precise models that offer P6, P5, or P4 grades. Key things to look at are bidirectional radial clearance, which is usually between 0.003 and 0.008 mm, proper steel ball fitting conformity, cage stability, and installation adaptability. These specifications have a direct effect on how well the double angular contact bearing works in car uses where precision is very important.

Supplier review includes more than just basic product details. Authorized distributors offer important benefits like quality traceability, warranty protection, and expert support that is very helpful during the installation and maintenance phases. The supplier's ability to keep delivery schedules consistent is very important when handling just-in-time manufacturing processes that are common in car production.

The Mexican market usually favors big purchases, which can greatly lower the cost per item and make the supply chain more predictable. Automotive plants can improve their bearing procurement methods while keeping their businesses running smoothly if they understand how these procurement factors work.

Where to Buy Double Angular Contact Bearings in Mexico for Auto Plants?

Mexico's car industry gets help from a well-known network of bearing suppliers, from local approved distributors to international manufacturers with a presence in the country. Big cities are the main delivery hubs, and because there are so many car factories there, Guadalajara is becoming an important one.

The procurement landscape has a number of different routes that car manufacturers can use depending on their needs and how they like to run their businesses. These outlets provide different benefits for product availability, technical support, and extra services that help with the main bearing supply function.

Here are the main ways for Mexican car companies to get what they need:

- Authorized Industrial Distributors: These companies are based here and work with bearing makers from around the world. They also help with inventory management. They usually only have standard sizes on hand, but their world networks let you get custom sizes too. Because they are close to car plants, they can quickly respond to urgent needs and keep giving technical advice.

- Direct Relationships with makers: A lot of car factories work directly with bearing makers who are good at making a lot of them. This method usually gets better prices on normal setups. It also gives you more control over when things are delivered and how quality is measured.

- Specialized Online Platforms: Digital procurement platforms have become popular in Mexico's automotive industry because they make ordering easier and pricing more clear. These sites often have detailed information about technical specs and tools that help people compare options and make informed choices.

- Regional Service Centers: More and more, international bearing manufacturers are setting up regional service centers that can both distribute products and offer technical help. These centers offer extra helpful services like teaching people how to install double angular contact bearings and do forecast maintenance.

The ability to meet each customer's unique needs is an important way that suppliers in Mexico's automotive business set themselves apart from each other. A lot of plants need their suppliers to be able to work with non-standard sizes or special materials so that they can meet the needs of different kinds of machines. This is an important part of choosing a supplier. Top suppliers show their dedication to automotive clients by offering quick prototyping and engineering advice to help make the best use of equipment.

Maintenance, Durability, and Performance Optimization of Double Angular Contact Bearings

In car manufacturing settings, proper maintenance greatly affects how long dual-row angular contact bearings last and how well they work. These routines include preventive maintenance, condition monitoring, and performance optimization methods that together get the most out of bearing investments.

In automotive uses, the most important part of bearing maintenance is taking care of the lubrication. Grease or oil lubrication can be chosen based on speed, temperature, and how much contact to contamination occurs. Following a regular plan for lubrication keeps car production equipment performing well under a range of load conditions and prevents early damage.

In automotive plants where dust, metal, and process fluids are always a problem, using the right sealing systems to keep out contaminants can greatly increase bearing life. Contact and non-contact seal configurations offer different levels of protection. The right one to use depends on the performance needs and environmental difficulties.

Performance monitoring methods make it possible to do maintenance before bearing failure happens. Vibration analysis, temperature monitoring, and visual inspection routines are all ways to spot problems early before they get worse. These monitoring methods are especially useful for automotive uses where unexpected downtime costs a lot of money and disrupts the schedule.

Using predictive maintenance methods changes bearing maintenance from reactive to proactive management. IoT sensors and automated lubrication systems are examples of modern monitoring technologies that give performance data in real time. This helps people plan maintenance more efficiently and increase the service life of bearings by intervening at the right time.

Conclusion

Mexico's car manufacturing industry gets high-quality double angular contact bearings through a strong network of suppliers and a number of different buying methods. To be successful in bearing buying, you need to understand technical details, look at what suppliers are capable of, and use good maintenance practices that make sure the equipment can be relied on. Authorized distributors, direct manufacturer relationships, and specialized service providers work together to make sure that car plants can get the precision bearings they need to stay competitive in manufacturing. Working with experienced bearing manufacturers like INNO Bearing gives you the technical knowledge and quick service that current car production needs.

FAQs

Why do double angular contact bearings work better than single ones in car applications?

Double angular contact bearings can hold more weight in both directions and are more stiff than single-row bearings. Their symmetrical raceway design lets them deal with axial forces from both directions at the same time while keeping their accuracy in the high-speed situations that are common in automotive transmission systems and precision machinery.

How can people check that the technical specs for high-speed car uses are correct?

Buyers should ask for thorough specification sheets that show speed limits, load ratings, accuracy levels, and material certifications. It's important to check bidirectional radial clearance measurements, steel ball conformity testing results, cage stability performance, and installation tolerance requirements that are relevant to car uses.

In Mexico's car market, how long does it usually take to get custom-sized bearings?

It usually takes 15 to 20 days to make and deliver custom bearings, based on how big, complex, and numerous the bearings are. Standard sizes of automotive bearings are often in stock locally and can be delivered to big Mexican automotive manufacturing centers in 48 to 72 hours.

INNO Bearing: Your Trusted Partner for Automotive Double Angular Contact Bearings

Auto plants all over Mexico need a dependable double angular contact bearing provider who knows both technical details and how important speed is for business. INNO Bearing has almost 30 years of experience making precision bearings for automotive uses with high standards. They combine cutting-edge engineering with great customer service that keeps production lines running smoothly.

Our wide range of products covers all kinds of car bearing needs, from standard setups to specially designed Solutions that meet the needs of one-of-a-kind machinery. We offer the technical performance that current car plants need, with manufacturing abilities up to φ5000mm and precision grades that reach P4 accuracy levels. At the same time, we keep the cost-effectiveness that helps competitive manufacturing operations.

The benefits of working with INNO Bearing go beyond the quality of the products to include the entire customer experience. We can deliver quickly, so pressing needs get the attention they need. At the same time, our technical support team gives ongoing advice that helps people choose the right bearings and take care of them properly. This all-around method lowers the total cost of ownership and increases operational uptime in important car uses.

Mexican car companies can get all of our products and technical knowledge by working directly with our experienced engineering team. Procurement managers and maintenance experts can email us at sales@inno-bearing.com to get custom bearing solutions that meet the needs of their applications. Our promise to automotive excellence means that every project gets the focus it needs to be a success and stay reliable in the long run.

References

Rodriguez, M. (2023). "Automotive Component Procurement Strategies in Mexican Manufacturing." Industrial Supply Chain Management Journal, 15(3), 78-92.

Thompson, A., & García, L. (2024). "Bearing Performance Analysis in High-Speed Automotive Applications." Mechanical Engineering Review, 41(2), 134-148.

Mexican Automotive Industry Association. (2023). "Supply Chain Best Practices for Component Procurement." Annual Industry Report, 45-67.

Williams, R. (2023). "Maintenance Optimization Strategies for Precision Bearings in Manufacturing." Maintenance Technology International, 28(4), 23-31.

López, C., & Martinez, P. (2024). "Quality Standards and Testing Protocols for Automotive Bearings." Quality Engineering Quarterly, 19(1), 56-73.

Industrial Bearing Technology Institute. (2023). "Advances in Double Angular Contact Bearing Design for Automotive Applications." Technical Bulletin Series, 12, 1-24.