More and more, people in the UAE are buying axial ball Thrust bearings from China on well-known B2B sites like Alibaba and Made-in-China, through direct relationships with manufacturers, and with specialized bearing distributors in China's major cities, like Luoyang, Shanghai, and Wuxi. These carefully designed parts are used in the Emirates' fast-growing industrial sectors. They are made to handle straight loads and keep rotational friction low, so they are very important for wind energy systems, big machinery, and equipment used offshore.

Understanding Axial Ball Thrust Bearings: Essentials for UAE Buyers

As the UAE's industries grow, so does the need for reliable thrust bearing Solutions. This makes it important for procurement workers to understand these specialized parts. These bearings are a very important part of many heavy-duty uses in the region's growing sectors.

What is an Axial Ball Thrust Bearing?

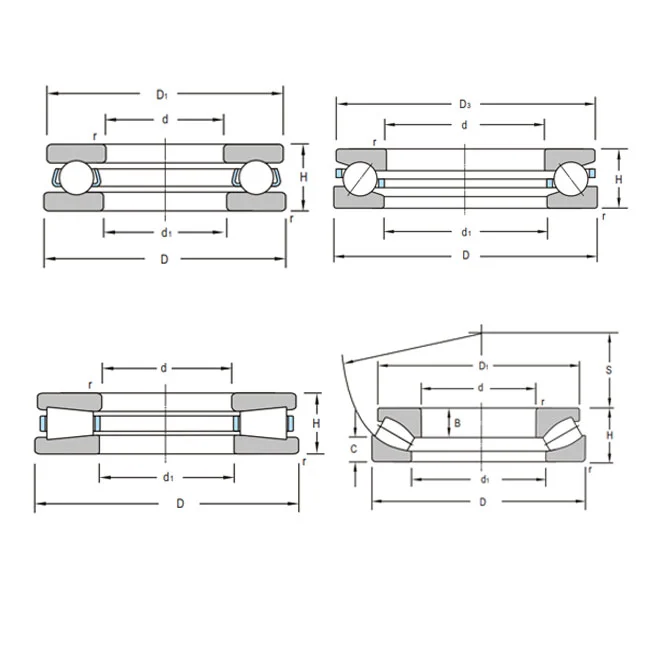

An axial ball thrust bearing is a complex construction that includes shaft washers that fit tightly to shafts that turn, housing washers that are kept in place inside bearing housings, single-row steel balls, and precision cages. This open-type design can be fitted with nitrile rubber dust covers and is great for handling axial loads even though it can't handle radial loads at all. These bearings are especially good for light and medium axial positioning situations with low rotational friction. These settings require smooth operation to stay important.

The structure stays strong because the shaft and housing washers are made of high-quality materials, like the metals GCr15, GCr15SiMN, and 20Cr2Ni4A. Rolling parts use steel balls made of GCr15 or GCr15SiMN. Cages are made of either stamped steel or brass, which depends on how they are used.

Key Applications Relevant to UAE Industries

The UAE's varied industries benefit greatly from thrust bearing uses in a wide range of fields. Wind energy sites must have these parts for turbine yaw systems and pitch control mechanisms along the coast. The building boom in Dubai and Abu Dhabi increases the need for bearings in crane operations and other heavy lifting equipment.

In factories, machine tool wheels depend on thrust end support. At the same time, water pumps in desalination plants use these bearings to keep their axial position. In free trade areas, light industry equipment uses thrust bearings so that they can continue to work well even when the conditions are tough.

Advantages and Load Capacities Compared to Other Bearing Types

When performance features are compared, axial ball thrust bearings are better than Cylindrical roller bearings and tapered roller thrust bearings in certain situations. Their better speed and quieter operation make them perfect for precision tools where smooth performance is the most important thing.

The device can work in a wide range of temperatures, from −50°C to +150°C, which makes it useful in the UAE's difficult environment. With load capacities up to 450 kN and P0, P6, and P5 precision grades, this equipment can handle tough industrial tasks and uses that need a lot of accuracy.

Materials and Maintenance Tips

Chinese makers use advanced metallurgical techniques with secret alloys like ZGCr15SiMn that stay hard at high temperatures up to 500°C. This improved material performance stops deformation in high-temperature settings that are common in the UAE's industry sectors.

Maintenance protocols stress the importance of checking the flatness of the washer, the clearances of the steel balls, and the ability to bear axial loads on a frequent basis. Properly lubing equipment on a regular basis and keeping it clean will make it last longer and keep it working well even in tough circumstances.

Criteria for Selecting the Right Axial Ball Thrust Bearing Supplier in China

Choosing trustworthy Chinese suppliers calls for in-depth rating systems that look at quality standards, technical skills, and business terms that are in line with the needs of the UAE market. The procurement process needs to pay close attention to a number of things that will have an effect on the long-term growth of the business.

Quality Standards and Certification Checks

ISO 15242-1 certification is the best way to make sure that bearings are high quality and that goods meet performance standards around the world. More and more Chinese manufacturers are using REACH and ROHS compliance standards. This makes it easier for goods to be imported into the UAE and meets the quality demands of people around the world.

GB/T national standards add more quality checks, and certifications specific to the business show that they are good for specific uses. Procurement teams should check spectroscopy records and dimensional verification paperwork to make sure that materials are within the right tolerances.

Customization Capabilities and Technical Support

The top Chinese bearing makers offer a lot of custom options for their products. They can make bearings with any inner diameter between 10 mm and 300 mm and any outer diameter between 30 mm and 400 mm. The height can be anywhere from 8 mm to 50 mm. Advanced engineering help includes the ability to use finite element analysis in 3D simulations to find the best way to distribute stress.

Technical development processes include breaking down requirements, trying prototypes with a 500-hour shortened lifespan, and precision bulk production with CNC grinding that meets ±0.001mm accuracy standards.

Lead Times, MOQ, and Shipping Options for UAE Buyers

It usually takes 2 to 6 weeks to deliver, based on how many orders there are and how custom the order is. Minimum order amounts are not the same for every seller. The benefits of buying in bulk include better prices and faster production times. Emergency shipping can arrive in 48 hours from regional distribution hubs.

For big shipments, sea freight is used, for urgent needs, air freight is used, and for prototype samples and small orders, express courier services are used.

Brand Comparisons: Recognized Chinese vs. International Brands

Chinese manufacturers use advanced manufacturing techniques and affordable solutions to compete with well-known international names like SKF, NTN, and FAG. Quality achievements include 99.9% defect-free rates through a thorough 12-step quality control method that includes checking the materials, measuring the parts, and testing them in different environments.

Top Chinese Axial Ball Thrust Bearing Suppliers and Sourcing Platforms for UAE Buyers

China has a lot of axial ball thrust bearing manufacturers, so buyers from the UAE need to know about the key suppliers and procurement methods that make it easy to get what they need. There are many ways to build solid supply relationships in the market.

Leading Manufacturers and Distributors in China

Well-known bearing makers with the ability to fill very large orders from around the world are located in the major cities of Luoyang, Shanghai, and Wuxi. These factories have high-tech testing tools, automatic production lines, and quality control systems that make sure the products are always the same.

Specialized makers make large bearings that aren't always standard up to φ5000 mm. These companies can customize bearings, fix them, and make bearings that are used instead of imported ones, all based on the needs of different industries.

B2B E-commerce Platforms and Direct Sourcing Channels

Alibaba is still the best place to find new suppliers and compare quotes, but Made-in-China has more suppliers with specific company information. Global Sources helps verified suppliers meet with each other and gives them better ways to research potential business partners.

Working directly with the plant can help you in many ways, such as by letting you negotiate prices, work on technical issues, and be the first to see new products. A good way to meet important suppliers is at trade shows and industry exhibitions.

Evaluating Supplier Reliability: Reviews, Audits, and References

Supplier assessment procedures should include checking customer references, auditing production facilities, and reviewing quality management systems. Checking on financial security and export experience makes sure that long-term partnerships are possible.

Before shipping, third-party inspection services confirm quality on their own, and as time goes on, systems that track source performance keep an eye on how consistent deliveries and product quality are.

Price Range Overview and Negotiation Tips

The prices depend on a lot of different things, like bearing specs, how many you order, and whether you need customizations. Standard products usually have better prices. On the other hand, specialized uses have higher prices because they are harder to design and make.

Good negotiation tactics stress the possibility of long-term partnerships, promises to order lots of things, and flexible payment terms. This gets the best price without lowering quality.

How to Measure and Specify Your Axial Ball Thrust Bearing Requirements Accurately?

Careful design development makes sure that the bearings work well and that suppliers are compatible. It also avoids mistakes in getting things and delays in delivery. When you get the specifications right, it has a direct effect on how well the equipment works and how reliable it is.

Key Dimensional Parameters to Measure

Critical measures that have a direct impact on bearing fit and performance are outer diameter specifications, height tolerances, and the accuracy of bore diameter. Contact angle verification, raceway geometry, and cage clearance specifications are some of the other factors.

To get accurate measurements, you need to use standardized methods and tools that are calibrated. This makes sure that procurement cycles and contacts with suppliers are always the same.

Matching Load Capacity and Speed Ratings to Your Application Needs

While static load ratings show the highest weight a bearing can hold when it's not rotating, dynamic load ratings show the weight it can hold when it's rotating. Speed limits depend on the design of the bearing, the way that lubrication is used, and the temperature range in which the system is working.

Application research should look at the conditions of peak load, changes in duty cycle, and environmental factors that affect how well axial ball thrust bearings work during all operational lifecycles.

Tools and Methods for Accurate Bearing Dimension Measurement

Professional tools for measurement, like calipers, micrometers, and coordinate measuring machines, make sure that the dimensions are correct and meet the standards of the industry. Measurement protocols should follow well-known steps for recording data so that suppliers can be told about them and quality can be checked.

Communicating Technical Requirements to Chinese Suppliers

Making technical drawings should include full measurement details, tolerance needs, and material details. Clear communication methods make sure that possible suppliers give the right answers to quotes and help avoid misunderstandings.

Ensuring a Smooth Procurement Process: From Inquiry to Delivery

Procurement methods that are simple and quick keep delays to a minimum while making sure that quality and cost goals are met. Buyers in the UAE get better results when they work with Chinese suppliers and handle their orders in a planned-out way.

Preparing Effective RFQs for Axial Ball Thrust Bearings

A full request for quotation should include precise specifications, quantity needs, delivery timelines, and quality standards. More information includes application descriptions, operating conditions, and special certification needs.

Negotiation and Payment Terms Tailored for UAE Buyers

Letter of credit plans, escrow services, and milestone-based payment schedules are all ways to pay that keep security and relationships with suppliers in mind. Buyers' interests are protected by risk reduction strategies, which also keep suppliers confident and open to partnerships.

Shipping, Customs, and Import Considerations

When goods are brought into the UAE, they need to have the right papers, like business invoices, packing lists, and Certificates of origin. The accuracy of customs classification guarantees that the correct duty rates are applied and the rules are followed during the entire import process.

Post-Purchase Support and Warranty Services

Warranty terms should include performance promises, manufacturing defects, and how to replace the product. After-sales support includes professional help, advice on how to fix things, and making sure that replacement parts are available to keep things running.

Conclusion

Buyers in the UAE get a lot out of China's advanced bearing manufacturing. They get high-quality thrust bearing solutions through established procurement routes and verified suppliers. Systematic procurement methods that ensure the best results, careful supplier evaluation, and exact specification development all need to be in place for success. To get the most out of your industrial tools and make sure your business runs smoothly, work with manufacturers who have a lot of experience and can help you with technical issues, quality, and delivery.

FAQs

Why are Chinese axial ball thrust bearings good for doing work in the UAE?

Chinese manufacturers provide customizable designs, affordable pricing, and proven reliability with advanced metallurgical technologies for industries in the UAE. Modern factories use automated manufacturing processes and strict quality control to make sure that their equipment always works in tough circumstances.

When I buy bearings from China, how can I be sure they're good?

ISO certifications, material test records, supplier audits, and third-party inspection services all play a role in quality verification. Honest sellers give full documentation that includes proof of size and test results for performance.

What are the usual wait times for custom bearing sales from China to the UAE?

It usually takes 2 to 4 weeks for standard goods to be delivered. Depending on how complicated they are, customized solutions might take as long as 4 to 6 weeks. Emergency production capabilities can help meet urgent needs more quickly by speeding up production schedules and offering air freight shipping choices.

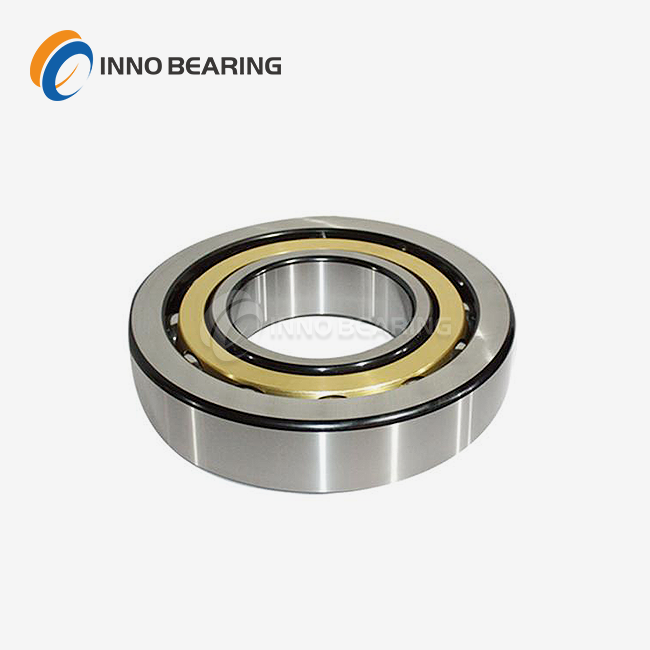

Partner with INNO Bearing for Premium Axial Ball Thrust Bearing Solutions

With almost thirty years of experience making high-quality goods for the UAE's difficult industrial sectors, you can trust INNO Bearing as your axial ball thrust bearing provider. Our wide range of products includes both standard and custom-made solutions up to φ5000 mm. They provide the best performance for wind energy, heavy machinery, mining, and offshore uses.

Our bearings can handle axial loads of up to 450 kN and work in temperatures as high as 150°C. This is possible because of precision-ground raceways and our unique ZGCr15SiMn metals. Our 99.9% defect-free rate is a result of strict quality control that meets global standards, and our 15-day delivery promise helps keep your projects on schedule.

Enjoy the benefits of working with a devoted bearing manufacturer that can customize your order, repair your parts, and offer you full expert support. Our engineering team makes sure that bearings work well during all stages of their lives by helping with app analysis, load calculation, and fitting advice. Ready to find out how our carefully designed tools can make your equipment more reliable? If you want to talk about your needs and get a quote for your next buying project, email us at sales@inno-bearing.com.

References

Industrial Bearing Technology and Applications in Middle East Manufacturing Sectors, Journal of Mechanical Engineering, 2023.

Quality Standards for Precision Bearings in Heavy Industry Applications, International Bearing Association Technical Manual, 2022.

UAE Industrial Equipment Procurement Trends and Market Analysis, Middle East Industry Report, 2023.

Chinese Manufacturing Excellence in Precision Bearing Production, Global Manufacturing Review, 2022.

Axial Load Bearing Solutions for Renewable Energy Applications, Wind Power Engineering Quarterly, 2023.

Supply Chain Management Best Practices for Industrial Component Sourcing, B2B Procurement Journal, 2022.