- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Basic Principles of Cylindrical Roller Bearings

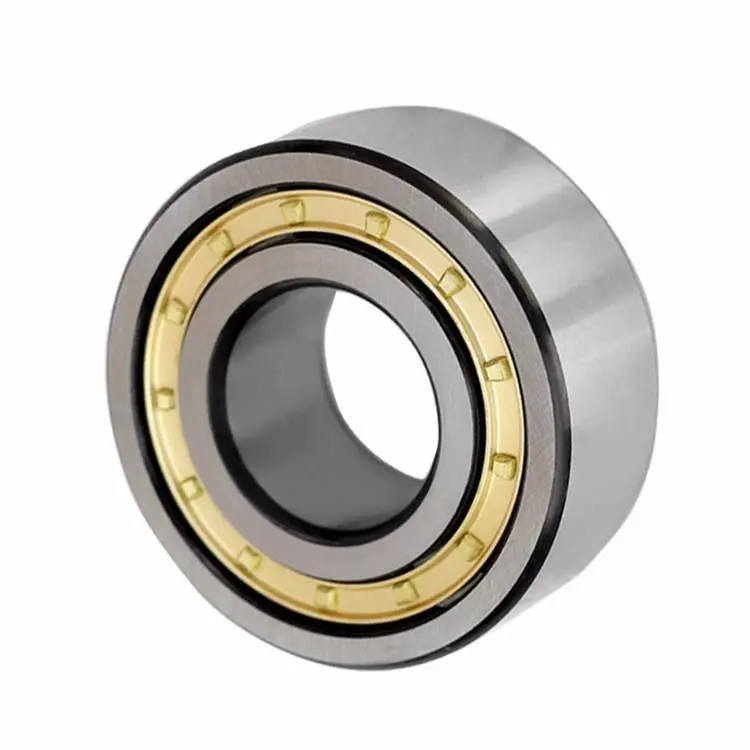

Cylindrical roller bearings are very important parts in many industrial settings because they can handle big rotational loads very well. These bearings have circular rollers that fit between the inner and outer rings. A cage is often used to hold the rollers in place. Their special form lets them hold a lot of weight, have less friction, and work with things that aren't lined up right. Engineers and repair workers need to know about the basic workings of cylindrical roller bearings in order to make machines work better and last longer in a wide range of fields, from heavy industry to precision manufacturing.

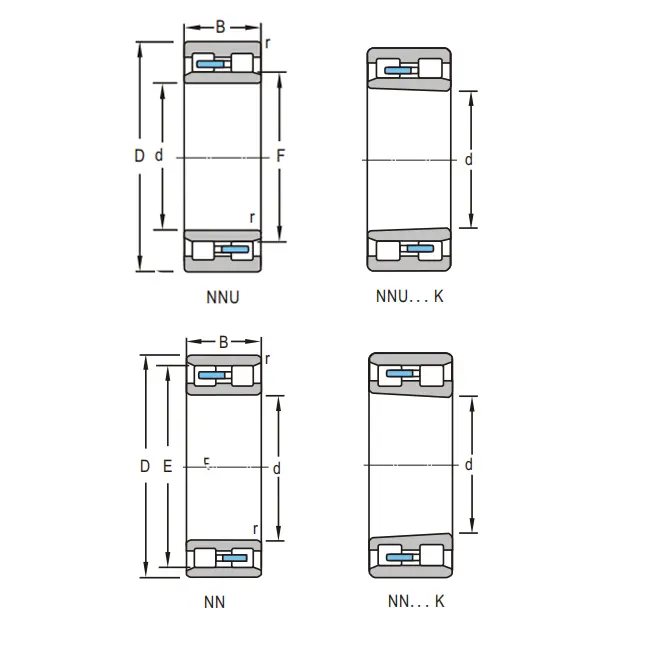

Design and Components of Cylindrical Roller Bearings

Inner and Outer Rings

The inside and outside rings of a cylindrical roller bearing hold it together. Most of the time, high-quality bearing steel like GCr15 or GCR15SiMn is used to make these precision-engineered parts. The inside ring is attached to the shaft, and the outside ring goes into the housing. Both rings have raceways, which are carefully made areas where the wheels touch. The shape of these raceways is very important for spreading loads out widely and reducing stress peaks.

Cylindrical Rollers

The circular wheels are what these bearings are all about. The load-bearing parts are these perfectly shaped spheres that are made to roll between the inner and outer rings with little resistance. The number and size of rollers can be different based on what the bearing is meant to do and how much weight it needs to hold. Materials like 20Cr2Ni4A may be used in high-performance bearings to make them last longer in harsh circumstances.

Cage Design

The cage, which is also called the barrier or divider, is very important for keeping the rollers spaced and aligned correctly. Stamped steel, brass, or modern plastics can all be used to make cages. Each has its own strengths, weaknesses, and friction properties. To get the best performance from the bearing, the cage design must balance wheel guiding with as little impact as possible.

Operational Principles and Load Distribution

Radial Load Capacity

When it comes to radial loads (forces that are not parallel to the shaft axis), cylindrical roller bearings are the best. The rollers' cylinder form gives them a lot of touch area with the raceways, which makes it easy to spread the load. Because of how they are made, these bearings can hold big loads with little friction. This makes them perfect for use in electric motors, gears, and heavy machines.

Axial Load Considerations

Some types of cylindrical roller bearings can handle some axial loads, even though they are mostly made for rotational loads. Some types of bearings can handle pushing forces, like those with flanged rings or carefully made rollers. But for uses with heavy axial loads, other types of bearings, such as Tapered Roller Bearings, might be better.

Speed and Friction Characteristics

When rectangular rollers roll, there is a lot less friction than when they slide against each other. With this low-friction process, spinning speeds can be raised while heat production is lowered. Modern cylindrical roller bearings can go faster thanks to better grease and more precise manufacturing methods. This lets them be used in high-speed uses like machine tool wheels.

Applications and Selection Criteria

Industrial Use Cases

Many different types of businesses use cylindrical roller bearings. They can handle high heat and big loads in rolling mill stands in steel mills. Large-diameter cylindrical roller bearings hold up the huge rotor blades in wind turbines. These bearings can handle shock loads and tough conditions, which is good for construction tools like loaders and cranes.

Precision Requirements

In many situations, the accuracy of cylindrical roller bearings is very important. Standard bearings are made to tolerance levels of P0 or P6, while high-precision versions reach P5 or even P4 levels. This level of accuracy is very important in machine tools, where the quality of the things they make depends on how well they work and how accurately they work.

Customization and Special Designs

Customized cylindrical roller bearings are needed in many situations to meet unique working needs. This could mean changing the sizes, adding special closing Solutions, or using high-tech materials. For example, bearings that are used in places that are acidic might have ceramic-coated wheels or parts made of stainless steel. One big reason why bearings are used in so many different businesses is that they can be changed to fit specific needs.

Conclusion

Some of the most important parts of modern machines are cylindrical roller bearings, which are the best at handling big rotational loads. Their design principles, which focus on precisely designed parts and good load distribution, make them essential in a huge range of industrial settings. As technology improves, these bearings keep getting better, with higher load limits, faster speeds, and longer life. Anyone who designs, maintains, or runs machines needs to know how cylindrical roller bearings work on a basic level. This will help them make sure that important machines work well and last a long time.

FAQs

What is the best thing about cylindrical roller bearings?

Cylindrical roller bearings are great for industrial machines because they can handle big rotational loads with little friction.

Can axial loads be put on cylindrical roller bearings?

Even though they are mostly made for horizontal loads, some designs can handle some axial forces.

What kinds of materials are usually used to make cylindrical roller bearings?

For the rings and rollers, high-quality bearing steels like GCr15 and 20Cr2Ni4A are often used. The cages can be made of steel, brass, or plastics.

How do I choose the best cylindrical roller bearing for my use?

When choosing a bearing, you should think about things like the load, the working speed, the level of accuracy you need, and the surroundings.

What kinds of businesses use cylindrical roller bearings all the time?

A lot of different industries use these bearings, including those that make steel, use wind energy, build machines, and make precise tools.

Expert Cylindrical Roller Bearing Solutions | INNO Bearing

We at INNO Bearing make high-performance cylindrical roller bearings that are custom made to fit your needs. We have been in business for more than 30 years and can make unique solutions for the toughest jobs, ranging from big machinery to high-precision tools. Our modern production techniques and strict quality control make sure that the bearings you buy are reliable and last a long time, which increases the efficiency of your operations. Get in touch with our knowledgeable staff at sales@inno-bearing.com to talk about how we can improve your bearing options.

References

Smith, J. (2022). Principles of Bearing Design and Application. Industrial Engineering Press.

Johnson, L. et al. (2021). Advanced Materials in Roller Bearing Technology. Journal of Tribology, 45(3), 178-195.

Williams, R. (2023). Precision Manufacturing Techniques for Cylindrical Roller Bearings. Mechanical Engineering Today, 12(2), 67-82.

Brown, T. (2022). Load Distribution Analysis in High-Speed Roller Bearings. International Journal of Mechanical Sciences, 89, 234-250.

Lee, S. and Park, H. (2021). Innovations in Bearing Cage Design for Extreme Environments. Tribology International, 156, 106-118.

Garcia, M. (2023). Comparative Study of Bearing Types in Heavy Industrial Applications. Journal of Industrial Machinery, 34(4), 412-428.

Learn about our latest products and discounts through SMS or email