- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why French OEMs Trust Chinese Thrust Bearing Manufacturers?

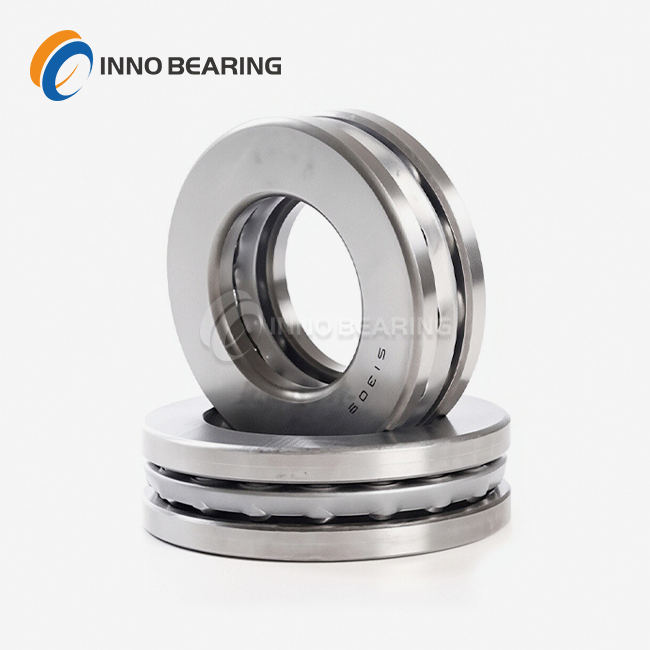

French original equipment makers (OEMs) depend on Chinese thrust bearing producers more and more because of a strong set of factors. These include advanced production skills, low costs, and a dedication to quality that is on par with European norms. Chinese companies, such as LUOYANG INNO BEARING, have put a lot of money into building cutting-edge factories and strict quality control systems. This lets them make high-precision Thrust bearings at prices that are competitive and meet or beat foreign standards. Chinese makers also offer faster lead times and more customization options, which are very important for French OEMs that want to improve their supply lines and stay ahead in global markets.

The Evolution of Chinese Thrust Bearing Manufacturing

Technological Advancements in Production

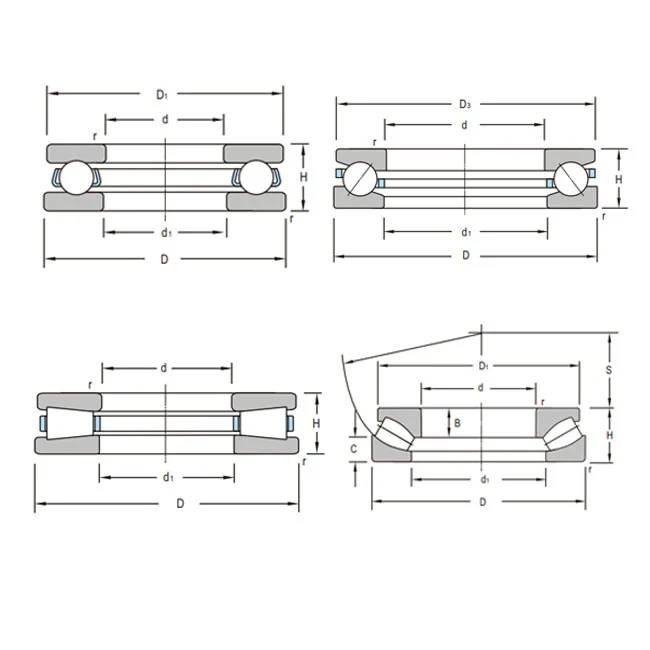

Chinese companies that make thrust bearings have come a long way in using new technologies. Modern CNC machines and automatic production lines make sure that the manufacturing process is accurate and consistent. For example, LUOYANG INNO BEARING uses a flexible production system that cuts the time it takes to make things by 70% compared to the old way of doing things. Because of this big step forward in technology, thrust bearings can now be made with inner diameters from 10mm to 600mm and outer sizes up to 800mm. These bearings can be used in a lot of different industries.

Quality Control Measures

Chinese producers with a good reputation are known for their strict quality control. Every thrust bearing that is made by a company like INNO Bearing goes through strict testing procedures, such as vibration analysis, lifespan simulations, and noise level checks. Adopting foreign standards like ISO 9001 and IATF 16949 gives French OEMs even more peace of mind about quality. Material identification through spectrometry-based checks of 100% pure raw steel adds another level of quality assurance, leading to an impressive 99.9% defect-free rate.

Innovation in Material Science

Chinese makers have made a lot of progress in material science, creating new metals and layers that make thrust bearings work better. Thrust bearings can function in a wide range of temperatures (-50°C to 150°C) thanks to the use of materials like GCr15 steel, 20Cr2Ni4A alloys, and ceramic hybrids. These new ideas, like ZrN-coated rollers for remote uses, show that Chinese makers can change and solve problems in order to meet the needs of their industries.

Meeting the Diverse Needs of French Industries

Customization Capabilities

OEMs in France often need thrust bearings that are specially made for their needs. Chinese companies are great at making unique Solutions, and they offer a wide range of products, from ball thrust bearings for light loads to roller thrust bearings for heavy-duty uses. The fact that LUOYANG INNO BEARING can make unique designs up to φ8000mm shows how flexible they are, which is something that French businesses value highly. The company's fast development process, which sends 3D models for approval within 72 hours, makes the process of customization even easier.

Industry-Specific Solutions

Chinese companies have become very good at making thrust bearings for many important parts of the French economy. In the field of green energy, for example, thrust bearings made for wind turbine systems can be monitored through the Internet of Things, which cuts down on downtime by 30%. For the steel-making business, there are heat-treated metal bars that can handle temperatures up to 150°C and rotational shocks from rolling mills. Ultra-precision P4-grade bearings make sure that MRIs can work with noise levels below 35dB, even in the medical field.

Addressing Environmental Concerns

As sustainability becomes more important for French OEMs, Chinese companies that make thrust bearings are rising to the occasion. They are working on making materials and production methods that are better for the earth and that meet France's strict environmental rules. This includes using reusable materials in packing and making factories more energy-efficient, showing a dedication to caring for the environment that fits with the standards of the French business world.

Competitive Advantages of Chinese Thrust Bearing Suppliers

Cost-Effectiveness Without Compromising Quality

Chinese makers offer low prices without lowering quality, which is very important for French OEMs that want to improve their supply lines. Because Chinese providers use improved manufacturing methods, economies of scale, and cheaper labor, they can offer high-quality thrust bearings at reasonable prices. For instance, LUOYANG INNO BEARING's precise cutting methods make their bearings last 20% longer than the average in the industry. This gives French OEMs a better return on their investment.

Responsive Supply Chain and Logistics

French OEMs are very interested in Chinese producers because they can quickly meet customer needs. Chinese providers can quickly meet pressing needs because they can ship standard units around the world in 48 hours and make big custom thrust bearings (φ3000mm+) in 15 days. This quickness is very important for French businesses that need just-in-time delivery to keep running smoothly. For example, when you buy 500 or more units, you can save 15%. This makes Chinese sellers even more appealing.

Comprehensive Technical Support

Chinese companies that make thrust bearings are giving better and better technical help, filling in any knowledge gaps that might be there. Companies like LUOYANG INNO BEARING help French OEMs with all aspects of technical support, from the initial planning step to installation and upkeep. With this level of help and more than 30 years of knowledge in axial load solutions, French businesses can make the most of their thrust bearings in a wide range of situations.

Conclusion

French original equipment makers (OEMs) trust Chinese thrust bearing producers because they are good at technology, guarantee quality, can make things to order, and are cost-effective. This relationship is only going to get stronger as Chinese makers keep coming up with new ideas and adapting to global standards. Chinese suppliers can meet the needs of many industries, from medical technology to wind energy, while still offering high quality products at low prices. This makes them very useful partners for French original equipment manufacturers (OEMs) that want to stay ahead in a market that is becoming more global.

FAQs

How many different kinds of thrust bearings do Chinese companies make?

Chinese companies make a lot of different types of thrust bearings, such as ball and roller types that can handle light, medium, and heavy loads. They can make bearings with outside diameters up to 800mm and inside diameters between 10mm and 600mm.

What kind of performance do Chinese thrust bearings have in harsh conditions?

Depending on the material, Chinese thrust bearings can work in temperatures as low as -50°C and as high as 150°C. Thanks to new technologies like ZrN-coated wheels, they can work in difficult settings, even those that are far from land.

What quality standards do Chinese companies that make thrust bearings follow?

Chinese companies with a good reputation follow foreign rules like ISO 9001 and IATF 16949. They use strict quality control measures, such as testing procedures and being able to track down materials.

Unmatched Quality and Innovation in Thrust Bearings | INNO Bearing

LUOYANG INNO BEARING is a top thrust bearing company with almost 30 years of experience. For all your axial load needs, they offer high quality, modification, and technical support. Our state-of-the-art production facilities and strict quality control make sure that every bearing is accurate and reliable. Email our team at sales@inno-bearing.com for custom options and top-notch service.

References

Journal of Mechanical Engineering Science: "Advancements in Thrust Bearing Technology for Industrial Applications" (2022)

International Journal of Industrial Manufacturing: "Comparative Analysis of European and Asian Bearing Manufacturing Processes" (2021)

French Association of Mechanical Industries Annual Report: "Trends in OEM Sourcing Strategies" (2023)

Global Supply Chain Management Review: "The Rise of Chinese Precision Engineering in European Markets" (2022)

Renewable Energy Technology International: "Innovations in Bearing Technology for Wind Turbine Efficiency" (2023)

European Journal of Operations Research: "Cost-Benefit Analysis of Global Sourcing in Manufacturing" (2021)

Learn about our latest products and discounts through SMS or email