One of the most important choices in today's competitive industrial world is picking the best materials to make slewing ring bearings. Engineering directors, sourcing managers, and quality testing teams must make this choice every day. These important parts make it possible for wind turbines, cranes, mining equipment, and ocean platforms to turn smoothly in any direction while supporting heavy weights. The material choice directly affects the operational reliability, service life, and resistance to fatigue. These are the kinds of things that can make or break a project worth millions of dollars. This all-inclusive guide helps mechanical engineers, purchasing managers, OEM project leads, and strategic procurement experts who need to get the details of their bearings right. When machine failure isn't just expensive, but disastrous, knowing material properties is very important.

Understanding Slewing Ring Bearing Materials

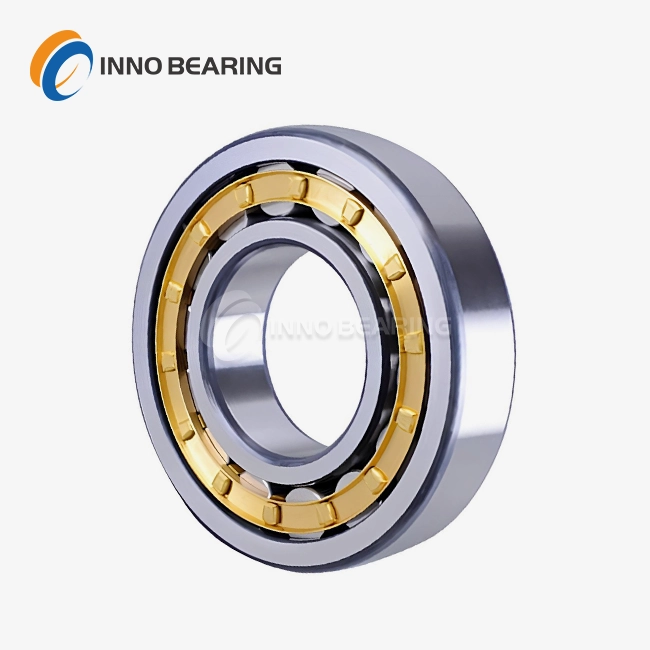

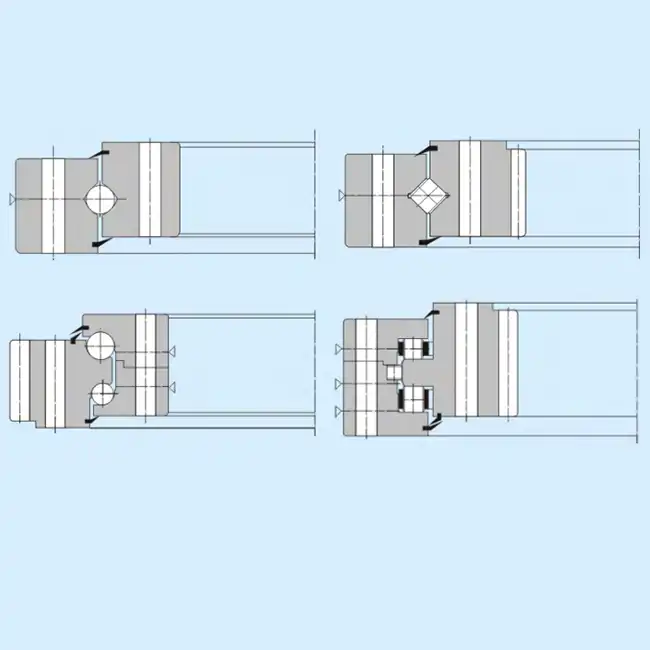

Slewing ring bearings are complex and amazing feats of engineering. They allow heavy machinery to turn while withstanding incredible stress from both mechanics and the environment. These parts, which include a fixed ring, a spinning ring, rolling elements, cages, and seals, all work together perfectly to make sure they always work right. The rolling parts, which can be set up in either a single-row or double-row design, deal with certain types of weight distributions. At the same time, the cages stop harmful collisions and the seals keep important raceways clean.

Core Material Properties That Matter

Four basic properties that affect bearing function are important to think about when choosing a material. The strength properties of the parts allow them to resist axial loads of up to 15,000 kN and radial loads of up to 9,000 kN without bending or breaking. Wear resistance stops the surface from breaking down over millions of spinning cycles, and corrosion resistance guards against tough conditions, from being sprayed with salt to chemicals getting on the surface. Fatigue tolerance makes sure that performance stays steady over long periods of time, often for decades in very important cases.

Common Material Categories and Applications

The industry depends on three main types of materials, each with its own benefits. Alloy steels, especially the 42CrMo and 50Mn grades, are used in heavy-duty uses because they can hold more weight and are more reliable than other options. Stainless steel versions work best in places where defense against oxidation is very important. When it comes to weight-sensitive applications that need to lower friction, advanced composite materials can be used as a specialized option. However, they are usually used alongside metal parts instead of replacing them.

In-Depth Analysis of Top Materials for Slewing Ring Bearings

Today, slewing ring bearings are made with carefully chosen materials that go through a lot of different treatment steps to get the best performance. Each type of material has its own benefits that are best for certain ways of working and environmental issues.

Alloy Steel Excellence in Heavy-Duty Applications

In tough situations where high durability and load capacity are most important, alloy steels are still the best choice for the business. The 42CrMo grade uses chromium-molybdenum alloying to get great strength, and the 50Mn grade uses manganese to get great wear protection. Carburizing, cooling, and other heat treatments make surfaces harder so they don't bend under very high loads. These materials allow bearing assemblies to work consistently in construction equipment, where performance must never be compromised due to shock loads and the need for constant operation.

Rolling Element Material Specifications

Rolling elements use special bearing steels that are made in very specific ways so that they get the best strength and surface finish. GCr15 bearing steel holds its shape and resists wear very well under normal situations. When silicon and manganese are added to GCr15 alloys, they become better at resisting impact. This makes them perfect for uses where quick changes in load or shock conditions happen. These products are tested carefully to make sure they will always work the same way, no matter where they are used.

Advanced Sealing Material Solutions

Sealing materials are very important for keeping bearing systems clean and protecting the integrity of the lubrication. Nitrile rubber seals work well in normal situations where they are exposed to chemicals and temperatures that are not too high or too low. Fluororubber alternatives are better at withstanding high temperatures and harsh chemicals. This makes them very important for specialized use in the fields of metallurgy and chemical processes. Triple-lip seals make things more safe while keeping rotational economy high.

Factors Influencing Material Choice for Slewing Ring Bearings

Choosing the right materials for a project means carefully thinking about the needs of the business, the environment, and the costs that affect the total cost of ownership. When considering maintenance accessibility and supply chain logistics, engineering teams need to find a balance between short-term performance needs and long-term reliability standards.

Load Requirements and Mechanical Stress Analysis

Load capacity specifications based on real-world situations and safety margins affect the choice of materials used. In mining and metallurgy, heavy-duty uses need materials that can handle huge weights without changing shape. Wind turbines need materials that don't break down after millions of load cycles. When construction equipment is being used, it needs materials that can resist impacts and sudden heavy loads. When procurement teams know these exact needs, they can choose materials that maximize efficiency without spending too much.

Environmental Condition Considerations

The very hot and very cold temperatures, wetness, chemicals, and weather conditions in the workplace have a big impact on the materials that are chosen. When used in water, salt, and high humidity, regular parts would be ruined, so they need to be made of materials that don't rust. Metallurgical equipment used in high-temperature settings needs materials that stay strong when temperatures go over 150°C. In places where chemical handling happens, materials must be able to withstand certain chemicals that could make them fail early by corroding or breaking down.

Economic Analysis and Total Cost Optimization

Cost-benefit analysis goes beyond the price of the item itself. It also considers the costs over the entire lifetime of the item, how often it needs to be fixed, and how often it needs to be replaced. Premium materials often justify higher upfront costs by lasting longer and needing less frequent upkeep. The time it takes to get materials, the dependability of suppliers, and the effect on project schedules are all parts of the supply chain. The chance to buy in bulk can lower the cost of each individual item and make sure that the material specifications are the same for several jobs.

Maintenance and Longevity: Material's Role in Bearing Life Cycle

Material composition fundamentally determines maintenance requirements, service intervals, and operational longevity throughout slew ring bearing lifecycle management. Understanding these relationships enables maintenance engineers to develop proactive strategies that maximize equipment uptime while minimizing total cost of ownership.

Lubrication Compatibility and Service Intervals

Different materials exhibit varying compatibility with lubricants, directly affecting maintenance schedules and operational efficiency. Steel components typically require lithium-based greases that provide excellent load-carrying capacity and temperature stability. Specialized materials may demand synthetic lubricants that offer superior performance under extreme conditions. Surface treatments and coatings influence lubrication effectiveness, with some materials requiring more frequent service intervals to maintain optimal performance levels.

Wear Prevention and Corrosion Control Strategies

Proactive maintenance strategies focus on preventing wear and corrosion that could lead to premature failure and costly downtime. Regular inspection protocols identify early signs of material degradation before they progress to failure conditions. Proper storage and handling procedures protect materials from environmental damage during installation and maintenance activities. Protective coatings and surface treatments extend service life by creating barriers against corrosive elements and abrasive contaminants.

How to Choose the Best Material for Your Slewing Ring Bearing Needs?

Successful material selection requires systematic evaluation of application requirements, performance specifications, and procurement considerations that align with project objectives and operational demands. This process involves technical assessment, supplier evaluation, and quality verification procedures.

Application Requirements Assessment

Comprehensive application analysis begins with detailed load calculations, environmental condition assessment, and operational parameter definition. Engineering teams must consider maximum loads, rotational speeds, duty cycles, and environmental exposures that components will encounter throughout their service life. Size requirements range from compact applications with 100mm outer diameters to massive installations exceeding 4000mm, with heights varying from 8mm to 150mm depending on load requirements.

Procurement Best Practices and Supplier Selection

Successful procurement requires partnerships with manufacturers demonstrating proven expertise, quality certifications, and reliable delivery capabilities. Supplier evaluation should include ISO 9001 certification, material traceability systems, and testing capabilities that ensure consistent quality. Custom manufacturing capabilities become essential when standard configurations cannot meet specific application requirements. Technical support availability, including engineering consultation and installation guidance, adds significant value to the procurement process.

INNO Bearing: Your Trusted Partner for Premium Slewing Ring Bearings

For almost thirty years, Luoyang INNO Bearing Co., Ltd. has been making high-precision bearings that work well in the most difficult industrial settings. Our broad skill set includes R&D, custom design, advanced manufacturing, and full expert support. Our specialty is big and non-standard bearings up to φ5000 mm. We offer full customization, repair services, and import replacement that meets or goes beyond the specs of the original equipment.

Our high-tech testing tools and strict quality control checks make sure that every slew ring bearing meets exact size standards, maximum slewing flexibility, and minimal noise while moving. We can still produce quickly, and we offer detailed technical support for our precise and reliable bearings to industries such as heavy machinery, mining, power generation, wind energy, and offshore applications. Our promise to quality covers every part of the customer experience, from the first meeting to ongoing help.

Conclusion

Material selection for slewing ring bearings demands careful consideration of strength, durability, environmental resistance, and cost-effectiveness factors that impact long-term performance and reliability. Alloy steels continue dominating heavy-duty applications while specialized materials address specific environmental challenges and performance requirements. Successful procurement requires thorough application analysis, supplier evaluation, and quality verification procedures that ensure optimal material selection. The investment in premium materials typically justifies higher initial costs through extended service life, reduced maintenance requirements, and improved operational reliability. Understanding these material relationships enables engineering and procurement teams to make informed decisions that optimize performance while minimizing total cost of ownership throughout extended operational periods.

FAQs

What materials provide the best corrosion resistance for slewing ring bearings?

Stainless steel grades, particularly 440C, offer superior corrosion resistance making them ideal for marine and harsh chemical environments. Fluororubber seals provide additional protection against aggressive chemicals and high temperatures, while specialized coatings can enhance corrosion resistance for standard steel components in moderate exposure conditions.

How does material selection affect the load capacity of slewing ring bearings?

Stronger alloy steels like 42CrMo support higher load capacities due to superior mechanical properties and fatigue resistance. Material choice directly influences maximum axial and radial load ratings, with high-strength alloys enabling compact designs for heavy-duty applications while standard materials suit medium-duty requirements more cost-effectively.

Are composite materials suitable for all slewing ring bearing applications?

Composite materials excel in specialized applications requiring lightweight construction or reduced friction characteristics, but they currently supplement rather than replace traditional alloy steels in heavy-duty contexts. They prove most effective in precision applications where weight reduction and smooth operation outweigh maximum load capacity requirements.

Partner with INNO Bearing for Superior Slewing Ring Bearing Solutions

Transform your industrial applications with INNO Bearing's precision-engineered slewing ring bearings manufactured from premium materials optimized for your specific requirements. Our expert engineering team provides comprehensive material selection guidance, custom manufacturing capabilities, and rapid delivery Solutions that keep your projects on schedule. Experience the reliability of ISO-certified quality, competitive pricing, and dedicated technical support that has earned the trust of industry leaders worldwide. Contact Us at sales@inno-bearing.com to discuss your slewing ring bearing manufacturer requirements and discover how our advanced material solutions can enhance your equipment performance and operational efficiency.

References

Harris, T.A. & Kotzalas, M.N. (2020). Essential Concepts of Bearing Technology: Materials and Manufacturing Processes for Industrial Applications. CRC Press.

Hamrock, B.J., Schmid, S.R. & Jacobson, B.O. (2019). Fundamentals of Fluid Film Lubrication: Material Selection and Surface Engineering for Rotating Machinery. McGraw-Hill Education.

Budinski, K.G. (2018). Engineering Materials: Properties and Selection for Slewing Ring and Large Bearing Applications. Pearson Education.

Shigley, J.E., Mischke, C.R. & Brown, T.H. (2017). Standard Handbook of Machine Design: Large Bearing Materials and Manufacturing Standards. McGraw-Hill Professional.

Bhushan, B. (2021). Introduction to Tribology: Friction, Wear, and Lubrication of Large-Scale Rotating Components. John Wiley & Sons.

ASM International Handbook Committee (2019). ASM Handbook Volume 18: Friction, Lubrication, and Wear Technology for Industrial Bearing Applications. ASM International.