If you want to keep your equipment running smoothly and avoid catastrophic failures, you need to know when to change your slewing ring bearing. These precision-engineered parts are the backbone of heavy industrial machinery. They allow everything from wind turbines to port cranes to rotate smoothly in all directions while carrying heavy loads. When a bearing starts to fail, the signs are often minor, but skilled experts can see them right away. If you notice these signs early on, like strange shaking patterns, more noise, or less smooth spinning, it could mean the difference between planned maintenance and unplanned downtime that costs thousands of dollars an hour in lost work.

Understanding Slewing Ring Bearings and Their Critical Role

Slewing ring bearings are a crucial part of modern industrial processes because they allow for precise movement in harsh environments. These big bearings are made to handle complicated loading situations that involve axial, radial, and moment forces all at the same time.

Essential Design Components and Structure

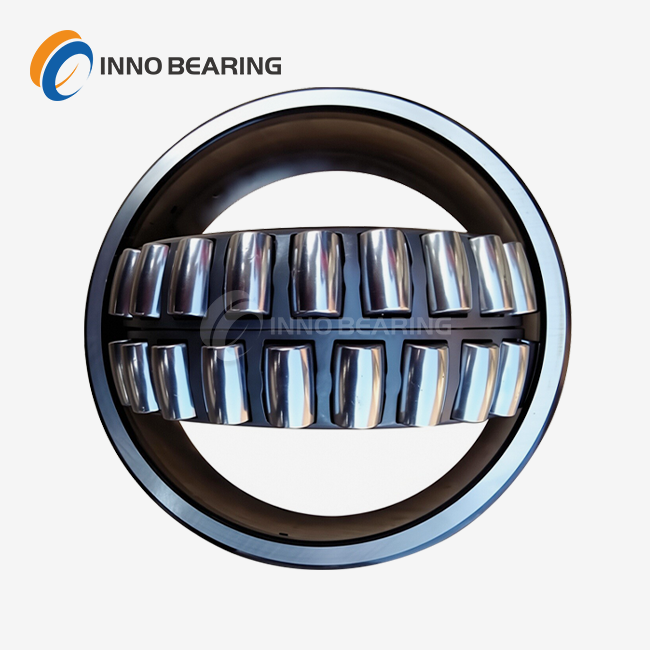

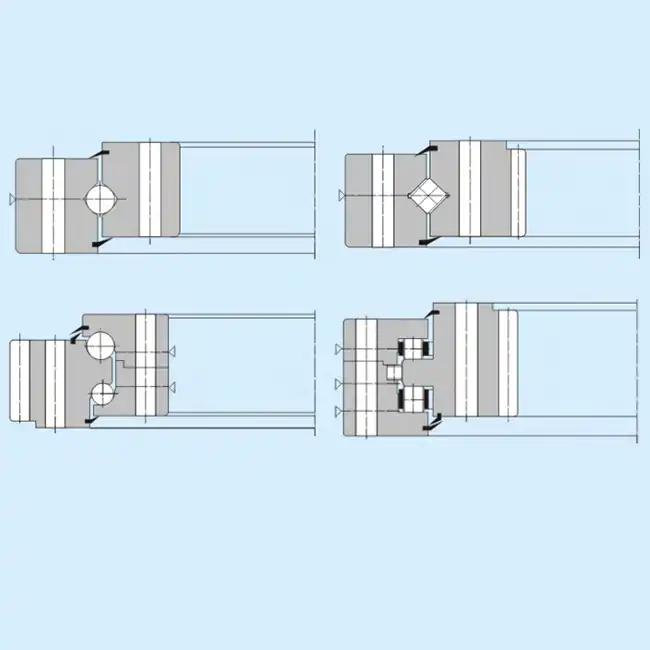

Knowing how these bearings are put together on the inside helps buying workers decide which ones to repair. Each slewing ring bearing has an outer ring that stays in place and an inner ring that spins. Rolling elements are placed between them to make motion smooth. Whether they are ball-type or roller-type, the rolling elements spread the load across the track surfaces, and cages keep the elements from running into each other while they're in use. Advanced closing systems keep the important racing areas clean so that external pollution doesn't hurt performance.

The level of structure complexity changes a lot depending on how much weight is needed. Moderate loads are handled well by single-row designs, while double-row setups offer more space for tasks that need better load distribution. The choice of material is also very important. The inner and outer rings are usually made of 50Mn or 42CrMo alloy steels, which are chosen for their high strength-to-weight ratios and resistance to wear.

Industrial Applications Across Critical Sectors

In many different types of industries, where dependability is important, these precise parts are used. Crane turntables and backhoe swing motors depend on them, and nacelle yaw systems and blade pitch control mechanisms in wind power installations depend on them as well. For accurate making, machine tools need very exact spinning. Port machinery uses them in ship-to-shore cranes that work in harsh sea settings.

Common Signs Indicating Your Slewing Ring Bearing Needs Replacement

When maintenance teams know the early warning signs of bearing wear, they can plan replacements ahead of time, avoiding expensive fixes and production delays. These signs usually show up slowly, so regular checks are important for good asset management.

Acoustic and Vibration Anomalies

One of the best ways to tell if an internal bearing is damaged is if it makes strange noises. Bearings that are healthy make low-level, steady sounds, while bearings that are breaking down often make grinding, clicking, or rolling sounds that don't happen at the same time. These changes in sound usually mean that the raceways are damaged, the rolling elements are worn out, or the greasing has broken down and needs to be fixed right away.

Vibration analysis gives more troubleshooting information because worn-out bearings send strange motion patterns through the body of the machine. Advanced condition tracking systems can pick up on these noises before they can be heard. This lets repair plans be planned ahead of time, which keeps operations running as smoothly as possible.

Thermal and Performance Indicators

Overheating is usually a sign that the grease is failing or that the internal friction is rising, which threatens the integrity of the bearing. Temperature tracking shows trends in the temperature that show how wear is progressing. Healthy bearings keep their temperatures fixed even when they are under a lot of stress. When performance goes down, it shows up as higher power costs, less smooth spinning, or too much pushback that affects the accuracy of the machinery.

Visual inspection of a slew ring bearing shows more danger signs, such as rust on the bearing housing's uncovered sides, worn-out seals, or dirt around the housing. These outside signs usually mean that there is more serious damage inside the bearing that needs to be replaced instead of being fixed.

Root Causes Behind Slewing Ring Bearing Failures

Understanding the basic causes of premature bearing failure helps people make better choices about what to buy and how to do preventative maintenance. These failure processes often work together, causing damage that builds up and speeds up wear beyond what is normally expected.

Lubrication and Environmental Factors

When a bearing fails too soon, it's usually because the oil film isn't thick enough. This lets metal-on-metal contact happen between the moving elements and the raceways. When a lube gets dirty from dust, water, or chemicals, it loses some of its usefulness and gritty bits are introduced that speed up wear. Extreme temperature changes, shock loads, and toxic atmospheres are some of the environmental stresses that normal bearings may not be able to handle without the right security.

Installation and Material Considerations

When construction isn't done right, things often get out of line, which makes the load distribution uneven across the bearing surfaces. This uneven traffic puts stress in certain areas, speeding up wear patterns that greatly shorten the operating lifetime. Even though they are rare in high-quality bearings, flaws in the materials or the way they were made can cause stress concentration places that lead to bigger breakdowns when they are used.

How to Decide When to Replace Your Slewing Ring Bearing?

When deciding when to replace something, you have to weigh a lot of things, like practical needs, cost, and your willingness to take risks in case something goes wrong. Approaches that are based on data are the most effective way to make these important choices.

Quantitative Assessment Criteria

Load capacity tracking shows that a bearing is wearing out by measuring changes in its performance. When a load-carrying capacity falls below what the application needs, it needs to be replaced, no matter what else is going on. Calculations of operational lifespan based on total stress cycles help estimate how much service life is left, while measurements of efficiency show rising friction losses that impact the overall performance of the machinery.

Condition tracking tools measure things like temperature trends, sound patterns, and audio emissions that are related to bearing health and can be used to make choices about replacement. With these tracking systems, forecast maintenance plans can be made that find the best time to replace something so that it costs the least.

Economic and Technical Considerations

When choosing new bearings, procurement professionals need to look at the total cost of ownership, which includes not only the original purchase price but also the costs of installation, the expected service life, and the upkeep needs. When used in certain situations, custom-sized bearings may work better, but standard versions are easier to find and cost less for most installs.

Maintenance Tips to Extend Your Slewing Ring Bearing Life

Proactive repair plans for a slewing ring bearing greatly increase the useful life of bearings while lowering the total cost of ownership. The main goals of these practices are to keep things running at their best and find problems before they do any lasting damage.

Inspection and Monitoring Protocols

Regular review plans that are based on how busy the business is make sure that problems are found early. Visual checks should include looking for broken seals, leaking oil, and surface rust that could mean damage from the surroundings. Noise research during operation finds sound patterns that trained staff can use to figure out how healthy the bearings are.

Temperature monitoring gives you constant feedback on how well a bearing is working, and moving data shows how things change slowly before they break. Keeping track of all test results creates past records that can be used to make choices about preventative maintenance and back guarantee claims when they're needed.

Lubrication and Handling Best Practices

By using the right oil and applying it in the right way, proper lube control greatly increases the life of bearings. Different types of lubricants are needed for different environments. Standard nitrile rubber seals work well for most tasks, while fluororubber choices are better at resisting oil and high temperatures.

To avoid damage during building, installation methods must exactly match what the maker says. By teaching maintenance workers the right way to handle bearings, you can avoid problems during installation that could affect how well the bearing works for its entire life.

INNO Bearing: Your Trusted Partner for High-Performance Solutions

In almost 30 years, INNO Bearing has become an expert at making accurate bearings for the toughest uses in the world. Our wide range of products includes all-purpose designs that come in both ball-type and roller-type options. These are made to handle a wide range of loading conditions while still being very reliable.

Advanced Manufacturing Capabilities

Our state-of-the-art factories make bearings with outer ring sizes ranging from 100mm to 4000mm, so they can be used in everything from small machines to huge industrial setups. For rolling elements, the advanced material range includes GCr15 bearing steel. GCr15SiMn options are also available for impact-resistant uses that need longer longevity.

Quality control procedures make sure that the dimensions are correct, the spinning is smooth, and there is very little noise, all of which meet the highest standards in the business. Each bearing goes through a lot of tests, such as checking the material's stability, making sure it works well by doing a lot of cycle tests, and making sure the noise level stays below 35dB.

Customization and Support Services

Our tech team works with customers to create unique Solutions that meet the needs of each application. We offer custom solutions that improve performance and life, whether it's changing seal configurations for tough locations or load rates to fit specific working profiles.

Technical support is available for the whole lifetime of a product, from helping with the original specifications to installing the product and suggesting regular upkeep. Our global distribution network makes sure that new parts and emergency help are available quickly when the business needs to keep running.

Conclusion

Knowing the early warning signs of slewing ring bearing wear lets you plan preventative repair strategies that keep operations running smoothly and increase the reliability of your equipment. The audio, temperature, and performance factors talked about can help repair workers who are trying to get the most out of their machines' downtime. Figuring out why bearings fail helps people make better choices about what to buy and how to do preventative maintenance that makes things last longer. When it's time to replace something, choosing a well-known brand with full expert help will ensure the best performance and long-term dependability. Three decades of specialized knowledge at INNO Bearing, along with advanced production skills and customer-focused support, make it possible for bearing repair plans that protect important industrial processes to work well.

FAQs

How often should you look for signs of wear on slewing ring bearings?

The number of inspections needed varies on how busy the operation is and the conditions of the surroundings, but every three months is enough for most uses. Situations with a lot of stress or important machines may need to be checked every month. Condition tracking systems can keep an eye on things all the time to help find the best preventative maintenance plans.

Should a slewing ring bearing always be changed when it gets broken, or can it be fixed?

Professional refurbishing services may be able to fix minor surface damage sometimes, but replacement is usually the best way to fix damaged bearings. It's hard to fix because of the complicated internal shape and high accuracy needs. Replacing it guarantees performance and protects the warranty.

What affects how much slewing ring bearings cost?

Some of the things that affect the cost are the bearing width, the load capacity needs, the material requirements, and the need for customization. Standard designs tend to have lower prices and faster delivery, while unique setups cost more but work better for certain kinds of tasks. Regular users can often save a lot of money by buying in bulk and making long-term deals with suppliers.

Partner with INNO Bearing for Superior Slewing Ring Solutions

When your equipment starts to show signs of bearing wear, you need to act quickly to avoid costly downtime and safety risks. INNO Bearing has a wide range of high-performance slewing ring bearings that are made for the toughest uses in the world. We can help you with your replacement needs. Our expert engineering team gives you one-on-one advice to make sure you choose the right bearings for your needs while also extending their life and making them more reliable. We are a reliable slewing ring bearing producer with almost 30 years of experience in the field. We offer the quality, customization, and technical support that keep your operations going smoothly. Email us at sales@inno-bearing.com to talk about your unique needs and find out how our tried-and-true solutions can improve the performance of your tools and the economy of your operations.

References

Harris, Tedric A., and Michael N. Kotzalas. "Essential Concepts of Bearing Technology: Rolling Bearing Analysis, Fifth Edition." CRC Press, 2020.

American Bearing Manufacturers Association. "Guidelines for Slewing Ring Bearing Maintenance and Inspection Procedures." ABMA Standards Publication, 2019.

ISO 492:2014. "Rolling bearings - Radial bearings - Geometrical product specifications (GPS) and tolerance values." International Organization for Standardization.

Budynas, Richard G., and J. Keith Nisbett. "Shigley's Mechanical Engineering Design, 11th Edition: Bearing Design and Application." McGraw-Hill Education, 2020.

Society of Tribologists and Lubrication Engineers. "Bearing Failure Analysis and Prevention Strategies for Industrial Applications." STLE Technical Publication, 2021.

Machinery Lubrication Magazine. "Predictive Maintenance Techniques for Large Diameter Bearings in Heavy Industry." Noria Corporation Technical Report, 2022.