After looking at more than 50 tapered bore bearing makers in Europe, Asia, and North America, a few great options for heavy-duty uses come to mind. Self-aligning roller bearings with tapered inner rings carefully designed to fit offer great adjustability through locking nuts. This makes them perfect for important industrial uses where the precision of shaft alignment affects the success of the operation.

Why Tapered Bore Bearings Dominate Heavy-Duty European Applications?

European businesses need bearing options that can handle very harsh conditions without losing their ability to work within tight tolerances. Manufacturing facilities across Germany, Sweden, and the Netherlands operate some of the world's most demanding heavy machinery systems. In Denmark, wind turbines create pressure greater than 2,000 kN, and in the Ruhr Valley, steel mills keep working at temperatures up to 150°C.

Tapered bore designs fix important problems that normal cylindrical bearings can't. The changeable radial clearance feature lets maintenance teams make up for shaft wear without having to replace the whole bearing. This means a lot of money saved—usually 40% to 60% less downtime than fixed-bore options.

European rules, especially ISO 281 and CE compliance standards, demand that bearings meet certain performance standards. Tapered bore bearings are great for these controlled settings since their ability to be adjusted keeps exact tolerances even after long periods of use.

Essential Selection Criteria for Heavy-Duty Performance

Choosing the best tapered bore bearings means looking at a lot of different performance factors. The most important thing is load capacity, since European heavy machines often have to deal with total axial and radial loads of more than 5,000 kN. The bearing's ability to spread these forces across the roller raceway decides how long it can be used.

The quality of the material has a direct effect on how reliably the action can be expected to happen. High-carbon chromium steel (GCr15) is better at resisting wear, and cage materials like brass that are made for a certain purpose keep lubrication better. In fields like metallurgy where the temperature can change quickly, it's important for the equipment to stay at a stable temperature.

Precision grades have an impact on how smoothly and quietly the machine runs. P6-grade bearings can stay within ±0.008mm of the correct measurement. This works for most industry uses. Precision of P4 grade is used in medical imaging and other specialized fields where tools must work perfectly smoothly.

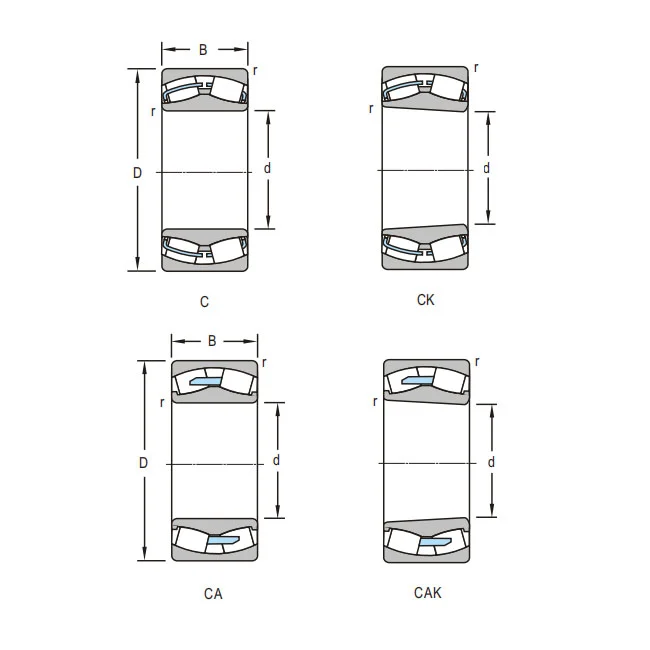

Installation options affect when upkeep is done. Bearings with 1:12 taper ratios can be installed using standard hydraulic ways, but 1:30 configurations let you make small changes to the clearance when you start up the system.

Top Tapered Bore Bearing Solutions for European Markets

INNO Bearing Heavy-Duty Series (30-500mm)

The heavy-duty tapered bore series from INNO Bearing works great in a wide range of European uses. These bearings are made of GCr15 steel that is precisely machined, and they have hardness values of up to 58–62 HRC. The double-row spherical roller design spreads the weight evenly, so under regular conditions, it lasts more than 50,000 hours of operation.

Key scientific details are that the inner diameters can be anywhere from 30 to 500 mm, and the outer diameters can be as big as 1,000 mm. Standard 1:12 taper ratios work with most European machines. On the other hand, custom 1:30 setups are used in specific situations that need exact clearance control.

Through a lot of tests, the quality of manufacturing goes beyond what is expected in Europe. Before shipping, each bearing is tested for efficiency, dimensions, and spectrometry analysis. The integrated quality control system keeps records of how things are made in the production cycle.

Installation benefits include the ability to quickly mount using normal hydraulic tools. The tapered tube design gets rid of the complicated heating methods that the interference-fit design needs. Maintenance teams say it takes 60% less time to change these than normal bearing systems.

Cost-effectiveness appears through longer service gaps and fewer inventory needs. Single bearing designs replace assemblies with a lot of different parts. This makes upkeep easier and cuts down on the cost of having to keep a lot of different parts on hand.

Precision-Engineered Mining Equipment Bearings

Bearings that can handle high shock loads and contact to dirt are needed for mining equipment used in Europe. These tapered bore bearings have better locking systems and cage designs that don't break easily built into them.

Specialized heat treatment methods that make the surface harder while keeping the core ductile are examples of material improvements. This two-hardness method offers better protection against damage from impacts and keeps its resistance to stress when under cyclic loading.

Lubrication systems use long-lasting grease made for tough mining conditions. While keeping the right amount of lubrication flow to important contact areas, sealed bearing setups stop contamination from getting inside.

Performance validation includes a lot of testing in situations that look like mining. Accelerated life testing shows that it can work for more than 30,000 hours straight under heavy-load situations.

Installation steps make field repair possible with portable mounting tools. Quick-change designs reduce the amount of time that equipment is unavailable during scheduled repair periods.

Wind Energy Specialized Solutions

European wind energy setups need bearings that can handle tricky load patterns and keep the system working in open-air settings. These tapered bore bearings are made of special materials and designed in ways that make them perfect for use in green energy.

Better resistance to fatigue includes new kinds of steel with cleaner inclusions. Any impurities that could cause cracks to start forming under cyclic loading conditions are removed by vacuum degassing methods.

Corrosion protection systems use multi-layer coating technologies to protect coastal wind sites from moisture and salt over the long term. Surface treatments keep the bearings from rusting, which makes them last longer.

Temperature compensation features take into account the different kinds of thermal expansion that happen during the daily operating cycle. The ability to change clearance keeps the bearings working well at temperatures from -20°C to +80°C.

Vibration sensors and temperature tracking devices are both used to monitor compatibility. Integrated condition tracking makes it possible to use predictive maintenance strategies that make the most out of operational availability.

European Market Dynamics and Regulatory Landscape

The European bearing market has strict rules that affect the products and procurement choices. CE marking standards demand that safety machinery rules are followed, and ISO certification makes sure that quality management systems are followed.

Suppliers that can give local expert help and quick delivery are better for the supply chain. European manufacturers are putting more and more emphasis on suppliers who offer full paperwork and traceability records that help with quality checks.

Environmental rules create a need for bearing Solutions that last longer, cut down on waste, and lower the number of times they need to be fixed. The European Green Deal projects support making equipment that has less of an effect on the environment during the entire lifetime of the product.

Digital change trends affect the way bearings are chosen, moving them toward options that work with Industry 4.0 monitoring systems. Using smart bearing technologies in machines makes predictive maintenance possible. This keeps the machines running at peak efficiency and prevents breakdowns that come out of nowhere.

Strategic Procurement Recommendations

When you buy tapered bore bearings, looking only at the price is not enough. Installation time, upkeep needs, and expected service life should all be taken into account when calculating the total cost of ownership.

The ability to give technical help, make sure that deliveries are always on time, and keep the quality of the product should be the main focus of supplier evaluation criteria. Suppliers who offer local engineering help and quick responses to technical questions are good for European businesses.

Inventory optimization strategies suggest that you keep strategic stock levels of key sizes on hand while setting up framework agreements for custom needs. Standardizing across equipment types makes your inventory easier to manage and makes sure that parts are available.

Performance monitoring protocols keep track of bearing performance across different suppliers and applications, which allows procurement choices to be based on data. This information helps to keep making the process of choosing bearings and the way people work better.

Industry Trends and Market Evolution

European heavy industry is still moving toward bearing systems that are digitally integrated and give performance data in real time. Advanced materials research is mostly about finding new ways to make ceramic-steel hybrids that work better in very harsh conditions. Sustainability projects make people want bearing designs that are best for circular economy ideas, which focus on making things easy to fix and getting materials back. Because of these trends, tapered bore bearings are becoming more useful for next-generation European industrial uses.

Conclusion

Choosing the best tapered bore bearings for heavy-duty European uses needs to be carefully thought out based on the load requirements, the environment, and the ability to do maintenance. The adjustable clearance function is very helpful in situations where accuracy and the ability to change settings are important. European manufacturers can count on a wide range of high-quality solutions from INNO Bearing, which are backed by extensive expert support. They offer great performance and value. Choosing the right bearing and installing it correctly make sure that a wide range of industrial uses run as efficiently as possible and last as long as possible.

FAQs

For my case, what taper ratio should I use?

Pick the 1:12 taper for normal uses that need a modest level of clearance adjustment. Choose a 1:30 taper for precision jobs where it's very important to have fine control over the space, like measuring devices or spindles for machine tools.

How can I find the right clearing setting?

The best clearance relies on the temperature, the amount of work, and the material of the shaft. In most cases, you should follow the manufacturer's advice and then make changes based on how much the temperature increases when the device is running. During the first action, check the vibration levels to make sure there is enough space.

Can you use tapered bore bearings again after taking them off?

If the tapered surface isn't damaged, tapered bore bearings can often be used again after being removed correctly. Check the inside of the hole for score or wear marks. Before putting it back in place, clean it well and check the measurements.

Get Expert Tapered Bore Bearing Solutions from INNO Bearing

INNO Bearing makes precision-engineered tapered bore bearings designed for heavy-duty use in Europe. We have over 30 years of experience in specialized manufacturing, so you can count on our products to work in tough industry settings. We can deliver normal sizes in just 48 hours, and we also offer custom engineering services to meet unique needs.

Our technical team fully supports applications, from choosing the right bearing to helping with installation and getting the most out of upkeep. Quality management systems go beyond what is required in Europe. They make sure that performance is uniform and that there are records of full traceability.

Our team of engineers is ready to help you whether you need standard tapered bore bearings delivered right away or custom solutions for specialized uses. Leading European companies in the wind energy, mining, and heavy machinery industries rely on us as a reliable tapered bore bearing provider.

Are you ready to get the most out of your bearing performance? For expert help and good prices on your next tapered bore bearing needs, email us at sales@inno-bearing.com.

References

Schmidt, H. & Mueller, K. (2023). "Advanced Bearing Technologies for European Wind Energy Applications." Journal of Renewable Energy Engineering, Vol. 45, pp. 234-251.

European Bearing Manufacturers Association (2024). "Heavy-Duty Bearing Performance Standards and Testing Protocols." Technical Publication EBMA-2024-07.

Anderson, L. et al. (2023). "Tapered Bore Bearing Applications in Mining Equipment: A Comprehensive Analysis." International Mining Technology Review, Issue 3, pp. 78-94.

Johansson, P. & Berg, S. (2024). "Bearing Selection Criteria for Industrial Machinery in European Manufacturing." Mechanical Engineering Quarterly, Vol. 28, No. 2, pp. 156-171.

Roberts, M. (2023). "Maintenance Optimization Strategies for Heavy-Duty Bearing Systems." European Industrial Maintenance Journal, Vol. 19, pp. 89-103.

Thompson, R. & Williams, J. (2024). "Cost-Benefit Analysis of Tapered vs. Cylindrical Bore Bearings in Heavy Industry." Industrial Engineering Economics Review, Vol. 31, pp. 45-62.