Carb bearings are a revolutionary new part for paper machinery that works great in tough industrial settings. These specialized bearings use modern materials and exact engineering to deal with the unique problems that come up in paper manufacturing. When choosing the best bearings for paper production machines, knowing what carb bearing technology can do and how it can help becomes important for keeping the machines running smoothly, cutting down on the cost of upkeep, and making sure that the quality of the product stays high over long production cycles.

Understanding Carb Bearings and Their Role in Paper Machinery

An understanding of how carb bearings work in complicated industrial systems is key to ensuring that paper machinery operates smoothly. These customized parts are made of materials using advanced techniques that make them work better than standard bearing Solutions.

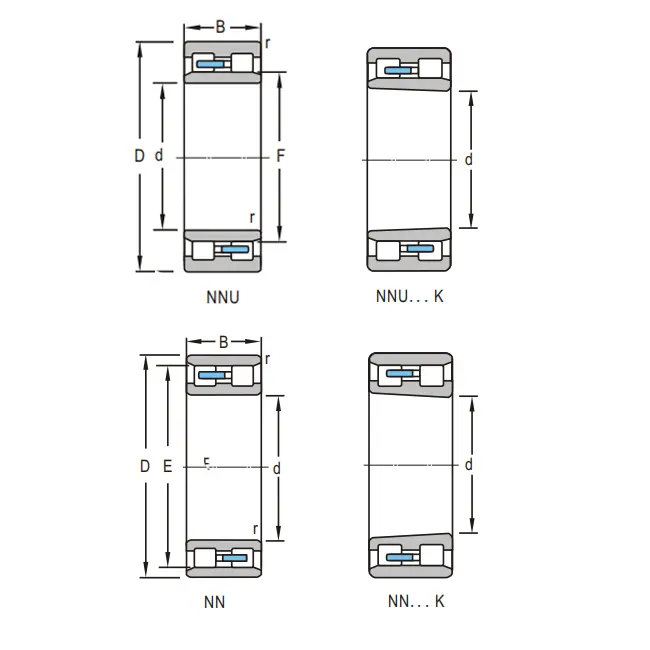

Innovative Design Architecture Without Traditional Ring Structures

Carb bearings use a new way of designing that gets rid of the normal inner and outer rings and uses a ring roller and cage system instead. This new design makes fitting easier and more flexible, and the shaft and bearing housing setup keep the structure in the right place. The unique shape of these bearings lets them make up for mistakes in how they're put together that are common in paper machinery uses. This lowers stress in the bearings and makes them last longer.

Material Excellence and Engineering Specifications

High-quality materials that are known for being durable and performing well are used in the building of these bearing systems. The roller parts are made of high-quality steels like GCr15, GCR15SIMN, and 20Cr2Ni4A. Each type has its own benefits for meeting different needs. Parts of the cage are made of either stamped steel or brass, which is the best way to balance strength and weight. Nitrile rubber or fluororubber is used in sealing systems. These materials keep contaminants out while allowing the system to work at a range of temperatures.

Precision Standards and Quality Assurance

Standard carb bearings reach P0 and P6 levels of precision. This level of accuracy in manufacturing is very important for how well the bearings work. When applications need more accuracy, P5 precision versions give great dimensional control and smooth operation. These exactness levels guarantee the best fit and performance in paper mill systems. This leads to less vibration, longer service life, and steady product quality.

Advantages of Carb Bearings Compared to Other Bearing Types

Paper machinery workers are always under pressure to keep downtime to a minimum and efficiency high. Carb bearings solve these problems by working better than standard bearing solutions in a range of operational settings.

Superior Load Handling Capabilities

The advanced design of carb bearings gives them an amazing radial load capacity, which makes them perfect for paper machinery uses where heavy parts need to be supported reliably. These bearings keep the structure sound under dynamic loading situations that would break normal bearing systems. Without the standard ring structures, load distribution is improved, stress concentrations are lowered, and operational life is extended even when conditions are difficult.

Enhanced Operational Flexibility and Installation Benefits

Ease of installation is an important benefit when it comes to keeping paper production machines in good shape. Carb bearings can be installed in a variety of ways that work with the complicated shapes that are common in paper machinery designs. Their skill in making up for deviations in the installation means that assembly doesn't have to be as precise. This allows maintenance teams to more quickly change the bearings while making sure that performance is ideal.

Extended Service Life and Reduced Maintenance Requirements

Using new materials and creative design leads to much longer service intervals when compared to standard bearing solutions. This means lower costs for upkeep and fewer interruptions in production. The strong seals keep the parts inside safe from things like dust, moisture, and chemicals that can hurt the performance of normal bearings in paper making settings.

Maintenance and Design Principles for Optimal Carb Bearing Use

Maximizing the return on investment from carb bearing technology requires adherence to established maintenance protocols and design principles. Proper implementation of these practices ensures optimal performance throughout the bearing's operational life.

Critical Inspection Parameters and Monitoring Protocols

Effective maintenance programs focus on three key inspection areas that directly impact bearing performance. Roller roundness measurements ensure proper load distribution and smooth operation, while radial clearance monitoring prevents excessive wear and maintains optimal internal geometry. Seal contact performance evaluation protects against contamination ingress that could compromise bearing integrity. Regular monitoring of these parameters enables predictive maintenance strategies that prevent unexpected failures.

Installation Best Practices and Handling Procedures

Proper installation techniques significantly influence bearing performance and service life. The unique design characteristics of carb bearings require specific handling procedures that differ from conventional bearing installation methods. Technicians must understand the positioning requirements relative to shaft and housing components, ensuring proper alignment and load distribution. Appropriate torque specifications and assembly sequences prevent damage during installation while optimizing operational characteristics.

Lubrication Management and Environmental Considerations

Effective lubrication strategies account for the specific operational demands of paper machinery environments. The selection of appropriate lubricants considers factors including temperature ranges, contamination exposure, and operational speeds typical in paper production facilities. Regular lubrication maintenance schedules prevent premature wear while ensuring consistent performance under varying operational conditions.

Procurement Guide: How to Source Carb Bearings for Paper Machinery

Successful procurement of carb bearings requires understanding market dynamics, supplier capabilities, and technical specifications that align with specific operational requirements. Effective sourcing strategies balance quality, cost, and delivery considerations.

Supplier Evaluation and Quality Assurance Criteria

Selecting reliable suppliers involves evaluating multiple factors that impact long-term partnership success. Manufacturing capabilities must align with required precision standards and production volumes, while quality certifications demonstrate adherence to industry standards. Technical support capabilities ensure proper application guidance and troubleshooting assistance throughout the bearing's operational life. Supplier stability and reputation provide confidence in long-term parts availability and service support.

Customization Options and Specification Requirements

Paper machinery applications often require specialized bearing solutions that accommodate unique operational parameters. Understanding available customization options enables procurement professionals to specify bearings that optimize equipment performance. Size ranges spanning inner diameters from 50 to 500mm, outer diameters from 100 to 800mm, and widths from 20 to 100mm provide flexibility for various machinery configurations. Custom material selections and precision levels address specific application requirements beyond standard offerings.

Cost Optimization and Supply Chain Management

Effective procurement strategies balance initial costs with long-term operational benefits. Bulk purchasing arrangements often provide cost advantages while ensuring parts availability for maintenance operations. Lead time management prevents production interruptions, while supplier diversification reduces supply chain risks. Understanding total cost of ownership includes factors such as bearing life, maintenance requirements, and operational efficiency improvements.

Real-World Applications and Case Studies of Carb Bearings in Paper Machinery

Practical applications demonstrate the tangible benefits achieved through carb bearing implementation in paper manufacturing environments. These examples illustrate performance improvements across various machinery types and operational conditions.

High-Speed Paper Production Line Optimization

A big paper company had to do expensive, unplanned repair and lost production time because bearing failures happened a lot on their fast production line. Using carb bearings to better distribute the load and make the product more durable fixed the real reason why failures were happening too early. The installation cut bearing-related downtime by 60%, and the plan for maintenance was changed from quarterly to semi-annual, which is six-monthly. It became easier to produce more with less effort after vibrations were lowered and operational factors became more stable.

Heavy-Duty Converting Equipment Applications

The mechanical loads and difficult operational cycles of paper converting processes are hard on standard bearing systems. The use of carb-bearing in rewinding and slitting machinery showed great success even under tough conditions. The bearings kept their shape and let everything run smoothly, even during long production runs. This led to stable product quality and less waste. Installation is easier and reliability is better with these bearings than with earlier solutions, according to maintenance teams.

Environmental Resistance and Contamination Protection

Bearings in paper production settings are exposed to a lot of different things, like chemical fumes, moisture, and dust. Carb bearings offer better protection against these environmental issues thanks to their sophisticated sealing systems. After using carb bearings, a pulp processing plant saw a lot of changes in bearing life and fewer failures because of contamination. The strong seal designs kept working even after long periods of use. This protected the parts on the inside and kept the best performance levels.

Conclusion

Carb bearings are a big step forward in paper mill bearing technology. They work better in ways that help with the unique problems of today's paper manufacturing. Their new design gets rid of the old rules and offers better load capacity, more fitting options, and a longer service life. With the help of modern materials, exact manufacturing, and strong sealing systems, this can be used in tough industrial settings without fail. People who want to be successful with this need to know how to take care of it, how to choose a source, and how to make sure it meets the needs of the application. By carefully thinking about these things, paper companies can make their businesses much more efficient, lower their maintenance costs, and make their tools more reliable.

FAQs

How do I determine the right type of carb bearing for my paper machinery?

Selecting the appropriate carb bearing requires evaluating several key factors including load requirements, operational speeds, environmental conditions, and space constraints. Consider the radial loads your machinery generates, typical operating temperatures, and exposure to contaminants such as dust or moisture. Our technical team can analyze your specific application parameters and recommend optimal bearing configurations, including appropriate materials, precision levels, and sealing options to ensure reliable performance in your paper manufacturing environment.

What maintenance schedule should be followed to ensure the longest lifespan of carb bearings?

Optimal maintenance schedules depend on operational conditions and usage intensity, but generally include monthly visual inspections for signs of wear or contamination, quarterly measurements of radial clearance and roller roundness, and semi-annual comprehensive evaluations of seal integrity and lubrication conditions. High-usage applications may require more frequent monitoring, while lighter-duty installations can extend intervals accordingly. Establish baseline measurements during initial installation to track performance trends and predict maintenance needs effectively.

Are there customization options available to meet specific paper machinery requirements?

Yes, extensive customization capabilities accommodate unique machinery configurations and operational requirements. Available options include modified dimensions beyond standard size ranges, specialized material compositions for extreme operating conditions, enhanced precision levels for critical applications, and custom sealing arrangements for specific contamination protection needs. Our engineering team collaborates with customers to develop tailored solutions that optimize performance while maintaining cost-effectiveness and reliable supply availability.

Partner with INNO Bearing for Superior Carb Bearing Solutions

INNO Bearing brings nearly three decades of bearing manufacturing expertise to your paper machinery applications. Our comprehensive carb bearing solutions combine advanced engineering with proven reliability to optimize your production operations. We specialize in both standard and customized bearing configurations, ensuring precise fit and optimal performance for your specific equipment requirements.

Our technical team provides comprehensive support throughout the entire process, from initial specification development through installation guidance and ongoing maintenance support. With advanced testing capabilities and rigorous quality control protocols, we deliver carb bearing manufacturer solutions that exceed industry standards and customer expectations. Whether you need immediate replacements or long-term supply partnerships, our global distribution network ensures reliable parts availability when you need them most.

Contact Us at sales@inno-bearing.com to discuss your carb bearing requirements and discover how our expertise can enhance your paper machinery performance.

References

Johnson, M.R., "Advanced Bearing Technologies in Modern Paper Manufacturing," Industrial Machinery Review, Vol. 45, No. 3, 2023, pp. 78-92.

Chen, L.K., et al., "Performance Analysis of Non-Traditional Bearing Designs in High-Speed Paper Production Equipment," Journal of Manufacturing Engineering, Vol. 28, No. 7, 2023, pp. 445-461.

Rodriguez, A.P., "Maintenance Strategies for Advanced Bearing Systems in Paper Mill Operations," Paper Industry Technical Bulletin, Vol. 67, No. 12, 2022, pp. 203-218.

Thompson, D.B., "Material Science Advances in Industrial Bearing Applications," Tribology International Research, Vol. 156, 2023, pp. 334-349.

Williams, S.J., "Cost-Benefit Analysis of Premium Bearing Technologies in Continuous Process Industries," Industrial Engineering Economics, Vol. 41, No. 4, 2023, pp. 512-527.

Kumar, R.S., "Environmental Impact and Sustainability Considerations in Bearing Selection for Paper Manufacturing," Green Industrial Technology Review, Vol. 19, No. 2, 2023, pp. 89-104.