To reduce the amount of heat that conical roller bearings make, you need to make sure that the lubrication systems work well, that the installation alignment is correct, that materials with better thermal properties are used, and that regular maintenance plans are followed. These Tapered Roller Bearings with angular contact geometry can handle thermal buildup in industrial settings by evenly spreading the load, using advanced synthetic lubricants, and including systems that watch the situation and stop temperature increases caused by friction.

Understanding the Fundamentals of Conical Roller Bearing Making Heat

The complex relationships between the rollers, the raceways, and the lubrication systems cause heat in conical roller bearings. These bearings are curved, which makes them good for combined load handling because of the way they touch each other. However, they can make heat in certain situations.

Primary Sources of Thermal Energy

In conical roller bearings, the most important source of heat is the friction between the rolling parts and the track surfaces. This happens when the lube film breaks down or runs out, which means that the metal surfaces can't stay apart. The roller angles and the inner ring raceway's curved shape make sliding friction parts that are not the same as pure rolling motion.

Cage friction plays a big role in heat building, especially when things are moving fast. The cage pockets and rollers work together to make heat, no matter if pressed steel or brass is used for the cage materials. Also, lubricant moving at high speeds makes the fluid hotter, which makes the temperature even higher all over the bearing assembly.

Load-Induced Thermal Effects

The radial and axial loads working together in conical roller bearings make the contact zones change shape. This change causes heat in the bearing steel through hysteresis losses. When loads exceed the limits set for the design, the higher contact forces speed up the generation of heat, which can cause temperature to rise very quickly.

Inner and outer rings that are not lined up properly make these heat effects worse by making the load distribution across the roller parts uneven. Even a little bit of misalignment can lead to edge loading conditions that raise the temperature and stress levels in that area.

Critical Factors Affecting Bearing Temperature Control

Choosing the right material is very important for controlling the temperature of conical roller bearings. New bearing steels like GCr15, GCr15SiMn, and 20Cr2Ni4A have different abilities to conduct heat, which affects how quickly heat moves through them. The microstructure that is created by special heat treatment methods has a direct effect on how well the bearing can conduct heat away from the contact zones.

Geometric Design Considerations

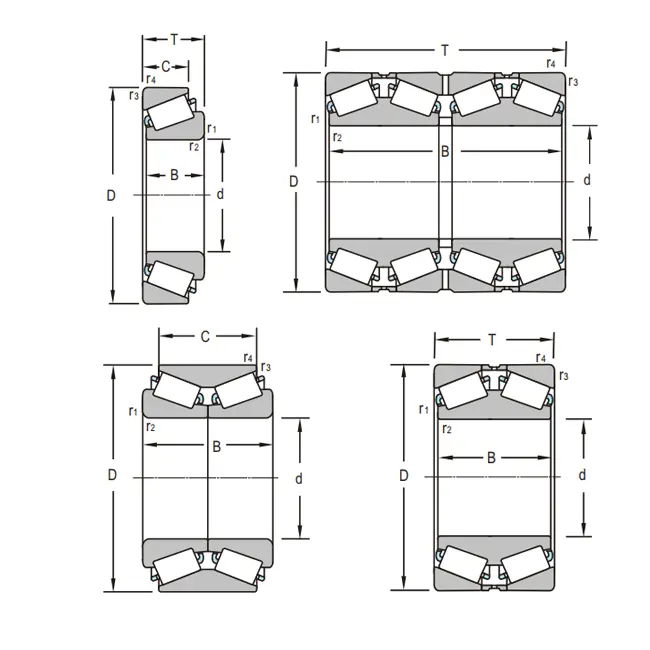

The contact angle that comes with conical roller bearing design has an impact on how much weight it can hold and how it reacts to heat. Optimized contact angles lower parts of sliding friction while keeping the bearing's ability to handle mixed loads well. The thermal footprint of the bearing under different working conditions is determined by the relationship between roller geometry, raceway curvature, and contact stress distribution.

Internal clearance specifications significantly influence heat generation patterns. Proper axial and radial space lets thermal expansion happen without too much preload, which would raise friction and temperature. Precision making to P5 or P4 levels of tolerance makes sure that the clearance relationships stay the same. This helps the system work better overall and keeps it cool.

Lubrication System Design

Choosing a lubricant is one of the most easily controlled parts of heat reduction tactics. Compared to mineral oils, synthetic lubricants with viscosity indices designed for the substance's thickness can keep film thickness stable over a wide range of temperatures. The thermal stability of improved lubricant formulations stops them from breaking down. This would otherwise lead to boundary lubrication conditions and fast temperature rises.

Lubrication delivery methods impact thermal management effectiveness. As they add new lubricant to touch zones, circulating oil systems keep heat from building up. Grease lubrication is simple, but base oil viscosity and thickener type must be carefully chosen to avoid channels that could leave important areas without enough lubricant.

Proven Methods for Thermal Optimization

The basis for good heat control in conical roller bearings is precise installation. Proper mounting keeps the bearing shape working as it should, which lowers friction and stops temperatures from rising.

Alignment and Mounting Procedures

Shaft and housing preparation needs very careful attention to the surface finish and measurement accuracy requirements. Proper fit tolerances stop too much interference that could preload the bearing past the design limits. At the same time, they make sure that there is enough contact for heat conduction routes. Angular alignment within the right limits stops edge loading, which makes a lot of heat in that area.

Installation tools and methods need to be able to work with the outer ring design that can be separated, which is a feature of single-row conical roller bearings. Properly adjusting the preload means finding the right balance between getting rid of internal clearance and avoiding the risk of too much loading, which raises warmth and friction.

Operational Parameter Optimization

Based on how fast they get hot, conical roller bearings are often used in situations where speed limits are in place. Rotational speed and heat generation are related in predictable ways that help people make choices about the operational envelope. Finding the dynamic load helps figure out safe working zones where thermal generation stays within the right limits.

Proper application planning for load distribution optimization lowers peak stresses that cause heat to build up. Engineers can choose the right bearing sizes that work well within thermal limits and meet performance needs when they know the total load capacity.

Advanced Monitoring and Maintenance Strategies

Temperature monitoring systems provide real-time feedback on bearing thermal conditions, enabling proactive maintenance decisions. Infrared thermometry and embedded temperature sensors offer different approaches to thermal surveillance, each with specific advantages for various application types.

Predictive Maintenance Techniques

Vibration analysis reveals thermal-related bearing degradation before catastrophic failure occurs. Changes in vibration patterns often correlate with temperature increases, providing early warning of lubrication breakdown or mounting problems. Spectral analysis techniques identify specific frequency components associated with thermal distress in conical roller bearings.

Oil analysis programs track lubricant condition and contamination levels that affect thermal performance. Particle counting, viscosity measurement, and chemical analysis provide insights into bearing wear rates and lubrication effectiveness. These monitoring techniques enable condition-based maintenance strategies that prevent thermal-related failures.

Maintenance Schedule Optimization

Lubrication intervals based on thermal considerations balance the need for fresh lubricant against over-greasing risks that can increase churning losses. Temperature-based relubrication schedules account for operating severity and help maintain optimal thermal conditions throughout the bearing service life.

Inspection procedures focus on thermal-related wear patterns and damage modes specific to conical roller bearings. Visual examination of roller and raceway surfaces reveals heat-related discoloration and wear patterns that indicate thermal stress conditions.

INNO Bearing's Advanced Thermal Solutions

INNO Bearing specializes in engineering conical roller bearings optimized for thermal performance across demanding industrial applications. Our extensive experience in wind energy, heavy machinery, mining, and port equipment has driven innovations in materials, design, and manufacturing processes specifically targeting heat reduction.

Material and Design Innovations

Our engineering team has developed specialized heat treatment processes that enhance thermal conductivity while maintaining the mechanical properties essential for heavy-load applications. Advanced steel grades and surface treatments reduce friction coefficients and improve heat dissipation characteristics compared to standard bearing materials.

Custom cage designs utilizing optimized materials and geometries minimize friction while improving lubricant distribution throughout the bearing. These innovations are particularly valuable in large-diameter applications where thermal management becomes increasingly challenging.

Application-Specific Solutions

Wind turbine gearbox applications benefit from our thermal-optimized bearing designs that handle the extreme load variations and environmental conditions characteristic of renewable energy systems. Our bearings maintain stable operating temperatures even under the demanding duty cycles common in modern wind installations.

Heavy machinery applications requiring large-diameter bearings up to φ5000mm present unique thermal challenges that our engineering team addresses through customized internal geometries and advanced lubrication system integration. These Solutions have proven effective in reducing operating temperatures by significant margins while extending service life.

Conclusion

Effective heat reduction in conical roller bearings requires a systematic approach encompassing proper selection, installation, lubrication, and maintenance practices. The thermal performance of these critical components directly impacts equipment reliability, operational efficiency, and maintenance costs across industrial applications. Understanding the fundamental mechanisms of heat generation enables informed decisions regarding bearing specifications, operational parameters, and maintenance strategies.

Advanced monitoring techniques and proactive maintenance approaches provide the tools necessary to optimize thermal performance throughout the bearing service life. The investment in proper thermal management pays dividends through extended bearing life, reduced downtime, and improved overall system reliability.

FAQs

What temperature range is considered normal for conical roller bearings in industrial applications?

Normal operating temperatures typically range from 40°C to 80°C above ambient temperature, depending on load, speed, and lubrication conditions. Temperatures exceeding 100°C above ambient often indicate thermal management issues requiring immediate attention.

How does bearing size affect heat generation and dissipation?

Larger bearings generally have better heat dissipation due to increased surface area, but they also generate more heat due to higher peripheral speeds and churning losses. The thermal mass of large bearings provides thermal stability but requires longer cool-down periods.

Can upgrading from open-type to sealed bearings help with heat management?

Sealed bearings can help maintain lubricant quality and exclude contaminants, but they may generate slightly more heat due to seal friction. The choice depends on application requirements and environmental conditions.

Partner with INNO Bearing for Superior Thermal Performance

INNO Bearing delivers industry-leading conical roller bearing solutions engineered for optimal thermal management in your most demanding applications. Our 30 years of manufacturing expertise and commitment to innovation ensure your equipment operates at peak efficiency while minimizing heat-related maintenance issues. Whether you need standard sizes or custom designs up to φ5000mm, our technical team provides comprehensive support from selection through installation.

Experience the reliability difference that proper thermal engineering makes in bearing performance. Contact Us at sales@inno-bearing.com to discuss your specific requirements with our conical roller bearing specialists.

References

Harris, T.A., and Kotzalas, M.N. "Advanced Concepts of Bearing Technology: Rolling Bearing Analysis." Taylor & Francis, 2006.

Palmgren, A. "Ball and Roller Bearing Engineering." SKF Industries Inc., Philadelphia, 1959.

Hamrock, B.J., Schmid, S.R., and Jacobson, B.O. "Fundamentals of Fluid Film Lubrication." Marcel Dekker Inc., New York, 2004.

ISO 281:2007 "Rolling Bearings - Dynamic Load Ratings and Rating Life." International Organization for Standardization.

Eschmann, P., Hasbargen, L., and Weigand, K. "Ball and Roller Bearings: Theory, Design and Application." John Wiley & Sons, 1985.

Tallian, T.E. "Failure Atlas for Hertz Contact Machine Elements." ASME Press, New York, 1999.