To choose the right thrust ball bearing for compressors and pumps, you need to think about the situations in which it will be used, the axial load requirements, and the environmental factors. These specialized bearings keep low friction coefficients while handling unidirectional or bidirectional axial loads. This makes them perfect for important pump and compressor applications. Engineers can choose the best way to make sure that equipment is reliable and maintenance costs are low when they understand the bearing specs, the materials used, and the way that people want the equipment to work.

Understanding Thrust Ball Bearings: Basics and Key Features

Thrust ball bearings are a special type of rolling element bearing that are made to handle axial loads in machines that are spinning. These bearings use steel balls between washers that have been carefully made to get the right fit. This spreads out the weight evenly and lowers friction so that they can work smoothly.

Construction and Design Principles

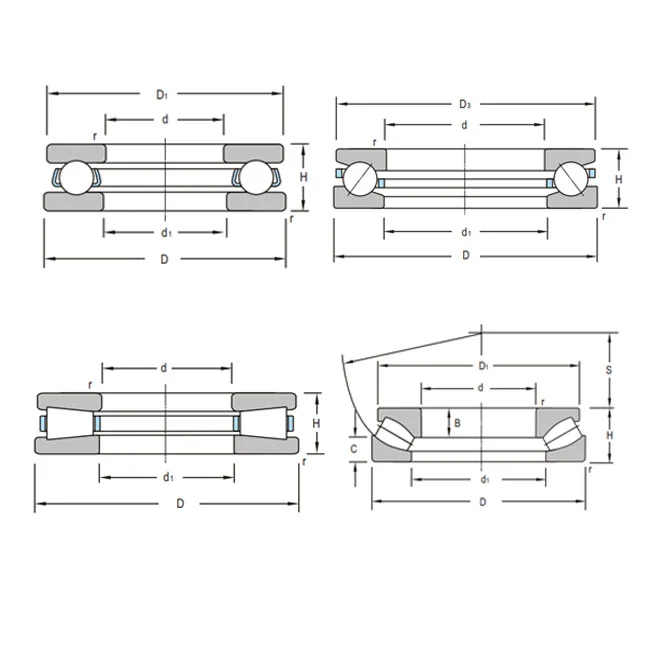

Single-row or double-row steel balls are used in the basic design of thrust ball bearings. A shaft washer, a housing washer, and single-row steel balls divided by a cage structure are all part of unidirectional designs. In bidirectional settings, there is a middle washer with double shaft washers and double-row steel balls so that the bearing can handle axial forces no matter which way they are pointing.

Choosing the right material is very important for how well the bearing works. GCr15, GCr15SIMN, and 20Cr2Ni4A are all examples of high-quality steel types that offer great resistance to wear and dimensional stability. The rolling parts are made of GCr15 or GCr15SIMN steel to spread the weight evenly. The cages are made of stamped steel or brass to keep the balls from touching and reduce friction.

Precision Grades and Size Specifications

Standard thrust ball bearings have an inner diameter of anywhere from 10 mm to 300 mm and an outer diameter of anywhere from 30 mm to 400 mm. The height specs are usually between 8 mm and 50 mm, which works for a variety of installation needs. Precision grades use the standard P0 and P6 systems. For uses that need higher rotational accuracy, precision models can get P5 grade accuracy.

Core Criteria for Selecting Thrust Ball Bearings in Pumps and Compressors

Choosing the right thrust ball bearings for use in pumps and compressors requires a deep understanding of how different operating factors affect the bearings' performance and lifespan.

Load Capacity and Speed Requirements

Thrust bearings are mostly chosen based on their axial force capacity. Engineers need to figure out the maximum operational loads, which include static and dynamic forces that happen during startup, normal operation, and emergency circumstances. In their normal form, modern thrust ball bearings can handle axial loads of up to 200 kN, but custom versions can handle even more.

It is important to keep in mind the limits on rotational speed, since high speeds can create spinning forces that damage the bearings. The relationship between load and speed makes operational envelopes that show safe working limits for certain bearing setups.

Environmental Operating Conditions

Very high or low temperatures have a big effect on the choice of bearing materials and the need for greasing. Standard bearings work well up to 150°C. In very extreme cases, specialty high-temperature versions with ceramic hybrid parts can handle temperatures over 500°C.

The amount of pollution in pumps and compressors requires the use of proper sealing methods. Open bearings get rid of heat better but need to be protected from the outside. Sealed bearings don't get contaminated but are worse at getting rid of heat.

Noise and Vibration Considerations

When noise levels need to be kept low, acoustic efficiency becomes very important. Premium thrust ball bearings are made very carefully and with new cage designs so that they make less than 35dB of noise. Vibration tolerance has an impact on the lifespan of bearings and the overall trustworthiness of a system. This makes it very important to choose the right bearings so that operational stability is maintained.

Thrust Ball Bearings vs Alternative Bearing Solutions: Making the Right Choice

Comparing thrust ball bearings against alternative Solutions requires understanding the specific advantages and limitations of each bearing type in pump and compressor applications.

Thrust Ball Bearings Advantages

Thrust ball bearings excel in applications requiring low friction operation and moderate axial load capacity. Their design inherently produces lower friction coefficients compared to roller alternatives, resulting in reduced energy consumption and heat generation. The ball-to-washer contact pattern distributes loads effectively while maintaining smooth operation at moderate speeds.

Alternative Bearing Comparisons

Thrust roller bearings provide superior load-carrying capacity for heavy-duty applications but generate higher friction and noise levels. Angular contact bearings offer combined axial and radial load support, making them suitable for applications where space constraints limit separate bearing arrangements. Cylindrical roller bearings handle high radial loads but lack axial load capacity, requiring combination installations.

Understanding these performance characteristics enables engineering teams to match bearing selections with specific application requirements, optimizing both performance and cost-effectiveness.

Procurement Considerations for Industrial Buyers

Successful procurement of ball thrust bearings requires evaluation of supplier capabilities, quality certifications, and delivery performance to ensure reliable supply chain management.

Supplier Qualification and Certification

Reputable thrust ball bearing suppliers maintain comprehensive quality management systems and industry certifications. Verification of manufacturing capabilities, testing facilities, and quality control processes ensures consistent product quality. Technical expertise and engineering support capabilities enable collaborative problem-solving for complex applications.

Customization and Lead Time Management

Customization capabilities become essential for non-standard applications requiring specific dimensions, materials, or performance characteristics. Leading suppliers offer custom solutions up to φ5000mm outer diameter with specialized materials and sealing configurations. Delivery performance directly impacts project schedules, making supplier selection crucial for time-sensitive installations.

Inventory management strategies including minimum order quantities and stocking programs help optimize procurement costs while ensuring adequate spare parts availability for maintenance operations.

Installation and Maintenance Best Practices

Proper installation and maintenance procedures maximize thrust ball bearing service life while minimizing operational disruptions and maintenance costs.

Installation Guidelines and Common Pitfalls

Correct installation procedures begin with thorough cleaning of bearing surfaces and surrounding components. Proper handling techniques prevent contamination and physical damage during installation. Alignment verification ensures uniform load distribution across bearing surfaces, preventing premature wear and failure.

Common installation errors include inadequate surface preparation, incorrect mounting procedures, and improper lubrication application. These mistakes can reduce bearing life significantly and compromise system performance.

Maintenance Strategies and Condition Monitoring

Proactive maintenance schedules that take into account working conditions and load cycles will make bearings work better. Regularly applying the right lubricant keeps protected films in place and lowers the rate of wear. Condition tracking through vibration analysis, temperature monitoring, and visual inspections makes it possible to find possible problems early on.

IoT sensors and predictive analytics are used in advanced maintenance to find the best times to do maintenance and avoid unexpected breakdowns. These technologies give performance data in real time, which helps with maintenance choices based on data.

INNO Bearing: Your Trusted Thrust Ball Bearing Supplier

INNO Bearing's specialty is making precision ball thrust bearings that are designed with difficult pump and compressor uses in mind. We have a wide range of products, including both standard and custom options that are made to meet the needs of different industries.

In standard configurations, our manufacturing skills include bearings with inner diameters from 10mm to 300mm and outer diameters up to 400mm. For special uses, custom options can fit up to a 5000 mm outer diameter. Some advanced materials, like steels GCr15, GCr15SIMN, and 20Cr2Ni4A, are very durable and work very well.

Quality assurance programs include tests that look at the materials, check the size, and make sure the product works. With strict quality checks and the ability to do very precise machining, our manufacturing methods achieve defect-free rates of 99.9%.

Conclusion

Choosing the best thrust ball bearing for use in pumps and compressors needs a very careful study of the loads, the thrust ball bearing's working conditions, and the environment. Knowing about bearing construction, material properties, and performance characteristics helps people make smart choices that boost the dependability and efficiency of their tools. Proper installation and maintenance increase the service life of bearings and lower the total cost of ownership. When you work with experienced bearing manufacturers, you can be sure you'll get technical help and high-quality goods that meet the needs of your industry.

FAQs

How do I determine the correct axial load capacity for my pump application?

Calculate the maximum axial loads during all operating conditions including startup, normal operation, and emergency scenarios. Consider dynamic load factors and safety margins when selecting bearing capacity ratings to ensure reliable operation.

What material considerations are important for high-temperature pump applications?

Select bearings with high-temperature steel grades such as GCr15SIMN or consider ceramic hybrid solutions for extreme temperature applications. Evaluate lubrication compatibility and thermal expansion characteristics for optimal performance.

Can standard thrust ball bearings handle bidirectional axial loads in compressor applications?

Bidirectional thrust ball bearings with intermediate washers and double-row steel balls specifically accommodate axial loads in both directions. These designs provide balanced load distribution and reliable operation in reversing applications.

Partner with INNO Bearing for Superior Thrust Ball Bearing Solutions

INNO Bearing delivers precision-engineered thrust ball bearings designed to exceed performance expectations in demanding pump and compressor applications. Our 30 years of manufacturing expertise, comprehensive customization capabilities, and commitment to quality ensure optimal solutions for your specific requirements. Experience our 30% faster delivery performance and exceptional technical support that keeps your operations running smoothly. Contact Us at sales@inno-bearing.com to discuss your thrust ball bearing needs and discover why leading manufacturers choose INNO Bearing as their trusted supplier.

References

Harris, T.A. & Kotzalas, M.N. (2019). Advanced Concepts of Bearing Technology: Rolling Bearing Analysis. 5th Edition. CRC Press.

Hamrock, B.J., Schmid, S.R., & Jacobson, B.O. (2021). Fundamentals of Fluid Film Lubrication in Bearing Applications. 3rd Edition. McGraw-Hill Education.

International Organization for Standardization (2018). ISO 12281-1:2018 Rolling bearings - Methods for calculating the modified reference rating life for universally loaded bearings. Geneva: ISO Press.

Palmgren, A. & Ball and Roller Bearing Engineering Society (2020). Ball and Roller Bearing Engineering Handbook: Design and Application Guidelines. 8th Edition. Marcel Dekker.

Stachowiak, G.W. & Batchelor, A.W. (2022). Engineering Tribology in Mechanical Systems: Friction, Wear and Lubrication. 4th Edition. Butterworth-Heinemann.

Warda, B. & Chudzik, A. (2021). "Fatigue Life Prediction of Thrust Ball Bearings in Pump Applications Under Variable Loading Conditions." Journal of Tribology International, Vol. 143, pp. 106-118.