Thrust ball bearings are designed to handle rotational loads and keep high-speed machines running smoothly. They are an important part of many different types of machinery. These specialized bearings use hardened steel balls placed between raceways that have been carefully polished so that they can handle axial forces with little friction, whether the force is moving in one direction or two. Today's manufacturing needs thrust ball bearing options that spread the load evenly, are always reliable, and last a long time in a wide range of industries, such as aerospace, automotive, and heavy manufacturing.

Introduction

Thrust ball bearings are important parts of high-speed machines that keep them running well and for a long time by supporting heavy loads that push straight along the machine's axis. Choosing the right thrust ball bearing is very important for keeping precision, lowering friction, and resisting wear in tough working situations. Engineering and procurement teams face more and more pressure to choose parts that improve performance while also lowering maintenance costs and working downtime.

This deep study focuses on applications, material choices, upkeep plans, and how to pick a supplier. It gives useful information for people who make buying and technical decisions in the industrial sector. Knowing these things helps people make smart choices about what to buy and makes businesses run more smoothly in manufacturing settings where accuracy and dependability are a must.

Understanding Thrust Ball Bearings in High-Speed Applications

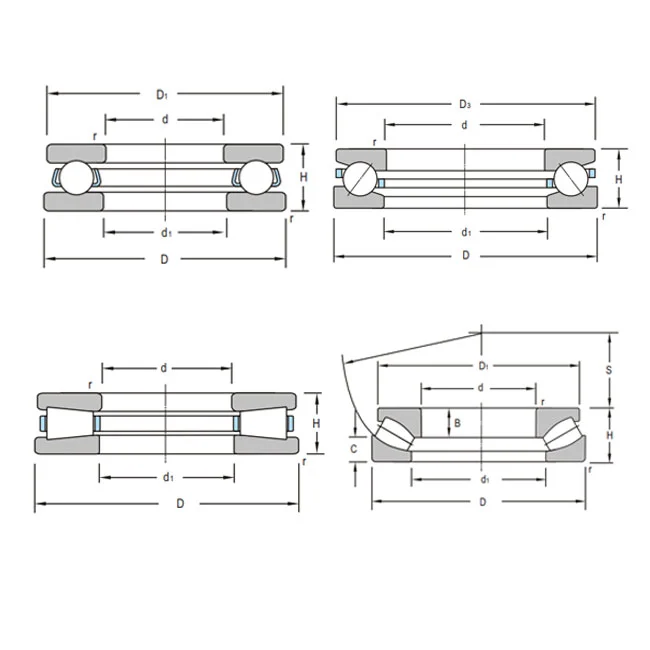

Thrust ball bearings are designed to handle axial loads in high-speed settings. They are completely different in design and how they work from radial or Thrust roller bearings. These parts have hardened steel balls, exact raceways, and special cages that help them reduce friction while spinning fast. The structure design includes either unidirectional setups with shaft and housing washers that support steel balls in a single row or bidirectional setups with intermediate washers that have double shaft washers and double-row steel balls.

Key Design Features and Materials

In challenging situations, the choice of material has a direct impact on how long it lasts and how well it resists corrosion. Shaft, housing, and intermediate GCr15, GCr15SIMN, or 20Cr2Ni4A washers are used in standard setups. GCr15 or GCr15SIMN steel is usually used for rolling parts. Cages can be made of anything from stamped steel to brass, and each material has its own benefits for reducing friction and managing heat.

Precision and Accuracy Standards

It is important to know about the different types of bearings, such as standard, high precision, sealed, or open, in order to be able to match performance needs with ways of doing upkeep. Standard P0 and P6 grade bearings work for general purposes, but precise models with P5 grade accuracy are used for important machines that need very little runout and great rotational accuracy.

Top 5 Industrial Applications of Thrust Ball Bearings in High-Speed Machinery

The latest ball thrust bearing styles can be used in a wide range of industries and can handle even the most difficult conditions. Each use has its own problems that need specific environmental resistance, precision tolerances, and material qualities.

Machine Tool Spindles

Thrust ball bearings are essential to the spindle accuracy and low thermal distortion of CNC machines and other precision industrial tools. These uses need very high levels of roundness, low vibration, and steady performance over long periods of time. The bearings must keep the right position while dealing with changes in the axial loads that happen when cutting.

Electric Motors and Generators

Electric motors used in a wide range of industries rely on thrust ball bearings to handle axial loads while maximizing performance and minimizing energy use. These bearings help motor applications a lot by providing low friction and precise load distribution. This leads to better electrical efficiency and cooler running temperatures.

Automotive Turbochargers

Automotive turbochargers need bearings that work effectively under very high temperatures and mechanical stress. These fast applications need parts that can handle quick changes in speed and temperature while keeping the same performance over the whole lifetime of the car.

Process Industry Pumps

Industrial pumps in the chemical, pharmaceutical, and food processing industries use sealed thrust ball bearings to keep dirt out, make sure the pumps last a long time, and keep them running smoothly. These settings often have problems like exposure to toxic materials, changes in temperature, and higher risks of pollution that need special bearing Solutions.

Aerospace Actuators

Aerospace applications demand precision and corrosion resistance as non-negotiable requirements. Flight control systems, landing gear mechanisms, and engine components utilize thrust ball bearings engineered to meet stringent reliability standards while operating in extreme environmental conditions including altitude variations and temperature extremes.

Comparative Insights: Thrust Ball Bearings vs. Alternative Bearings in High-Speed Situations

Selecting optimal bearing solutions requires comprehensive evaluation of thrust ball bearings against alternative designs, considering load capacity, speed tolerances, and operational requirements. Each bearing type offers distinct advantages depending on specific application demands and performance criteria.

Load Capacity and Speed Characteristics

Thrust roller bearings provide higher load capacity compared to ball bearing designs but typically operate at lower maximum speeds. Ball bearing configurations excel in high-speed applications where reduced friction and smooth operation outweigh maximum load requirements. The choice between these options depends on specific operational parameters and performance priorities.

Material Performance Comparisons

Material comparisons between traditional steel and ceramic options illustrate important trade-offs in friction, wear resistance, and investment cost. Ceramic hybrid designs offer superior temperature resistance and reduced friction but require higher initial investment. Steel options provide proven reliability and cost-effectiveness for standard operating conditions.

Sealing and Contamination Protection

Sealed versus open designs significantly influence maintenance frequency and contamination control, directly affecting operational uptime and total cost of ownership. Open ball Thrust bearings allow easier inspection and lubrication but require more frequent maintenance, while sealed designs protect against contamination but limit accessibility for routine servicing.

Procurement Considerations for Thrust Ball Bearings in High-Speed Machinery

Effective procurement strategies require comprehensive evaluation of suppliers, certifications, and support capabilities to ensure reliable supply chain performance. Procurement teams must balance cost considerations with quality requirements while maintaining operational flexibility for future expansion or modification needs.

Supplier Qualification and Certifications

Vetting suppliers requires verification of certifications including ISO quality standards and ABEC precision ratings that guarantee consistent quality and regulatory compliance. Working with established manufacturers or authorized dealers ensures access to genuine products, technical support, and warranty coverage that protects operational investments.

Customization and Volume Considerations

Customization options enable precise matching of ball thrust bearing specifications to application requirements, while volume considerations affect pricing and delivery schedules. Bulk purchasing often provides economies of scale beneficial for large production runs, but smaller quantities may be necessary for prototype development or specialized applications requiring unique specifications.

Logistics and Supply Chain Management

Global logistics considerations including shipping methods, inventory management, and after-sales service become pivotal for minimizing downtime and maintaining supply chain reliability. Regional warehouse availability, emergency replacement protocols, and technical support accessibility directly impact operational continuity and project success.

Maintenance Tips to Maximize Lifespan and Performance of Thrust Ball Bearings

Routine maintenance practices significantly extend bearing life while optimizing performance in high-speed machinery applications. Implementing systematic maintenance protocols reduces unexpected failures, minimizes operational disruptions, and maximizes return on bearing investments across industrial applications.

Lubrication Management

Proper lubrication selection and application intervals reduce friction and thermal buildup while protecting bearing surfaces from wear and contamination. Lubrication schedules must account for operational conditions, load characteristics, and environmental factors that affect lubricant performance and longevity.

Installation and Handling Procedures

Correct handling during installation prevents alignment issues and premature failures that compromise bearing performance. Specialized tools and techniques ensure precise mounting while avoiding damage to critical bearing surfaces, races, and rolling elements during assembly procedures.

Monitoring and Troubleshooting

Regular inspection enables early detection of wear patterns, contamination, or damage that could lead to catastrophic failure. Addressing common troubleshooting areas including abnormal noise, vibration, and temperature variations through scheduled maintenance optimizes reliability while safeguarding continuous operation in critical industrial applications.

INNO Bearing's High-Performance Solutions

INNO Bearing makes very precise thrust ball bearings and unique solutions for high-speed industrial machines. They sell these to customers in markets all around the world. Our wide range of products includes advanced materials, precision engineering, and a wide range of sizes to meet the needs of different applications in difficult working settings.

We can make products with inner diameters from 10 mm to 300 mm and outer diameters from 30 mm to 400 mm. Custom solutions can meet needs with outer sizes up to 5,000 mm. Standard height specifications are between 8mm and 50mm, but there are special designs with non-standard sizes and performance features for particular needs.

Quality assurance methods make sure that all of the bearings meet strict performance standards by doing a lot of tests, such as lifespan simulation, vibration analysis, and thermal cycling validation. Our precision grinding can get raceway tolerances within 0.001mm. From processing raw materials to final packaging and shipping, we also keep our production rates 99.9% free of defects.

Conclusion

Thrust ball bearings are important for high-speed machines that need to handle axial load correctly, have very little friction, and be very reliable. Understanding what goes into an application, what materials can be used, and how to take care of it all allows people to make smart choices about procurement that get the best performance out of tools while keeping costs down. The choice of bearing materials, configurations, and levels of precision must be based on the needs and standards of the operation.

Working with experienced manufacturers who offer technical knowledge, quality control, and full help for the entire product lifecycle is the only way to get it done right. INNO Bearing promises to make precise, high-quality bearings and help customers. This guarantees the best bearing options for a range of industrial uses that need performance and reliability without compromise.

FAQs

How do thrust ball bearings differ from thrust roller bearings in high-speed applications?

Thrust ball bearings utilize steel balls running in precise raceways, providing lower friction and smoother operation at high speeds compared to thrust roller bearings. While roller bearings offer higher load capacity, ball bearings excel in applications requiring high rotational speeds, reduced friction, and precise positioning accuracy.

What materials provide optimal performance for thrust ball bearings in harsh environments?

GCr15 and GCr15SIMN steels offer excellent durability for standard applications, while 20Cr2Ni4A provides enhanced performance in demanding conditions. Ceramic hybrid options deliver superior temperature resistance and corrosion protection for extreme environments, though they require higher initial investment compared to traditional steel configurations.

Can thrust ball bearings be customized for specific dimensional or performance requirements?

Manufacturing capabilities accommodate extensive customization including non-standard dimensions, specialized materials, precision tolerances, and environmental protection features. Custom solutions support prototype development, unique application requirements, and performance specifications beyond standard catalog offerings.

Partner with INNO Bearing for Superior Thrust Ball Bearing Solutions

When engineering teams and procurement professionals look for reliable thrust ball bearing suppliers, they can get all the help they need from INNO Bearing's wide range of production and technical skills. Our promise of quality, exact engineering, and customer support makes sure that bearings work well in tough industrial settings that need great accuracy and reliability.

Experience the advantages of working with a trusted thrust ball bearing manufacturer offering customized solutions, rapid delivery, and comprehensive technical support. Contact our engineering team to discuss specific requirements, request detailed quotations, or schedule technical consultations that optimize your machinery performance and operational efficiency. Reach out to us today at sales@inno-bearing.com to explore how our advanced bearing solutions can enhance your industrial operations.

References

Harris, T.A. & Kotzalas, M.N. "Essential Concepts of Bearing Technology: Fifth Edition." CRC Press, 2019.

Budynas, R.G. & Nisbett, J.K. "Shigley's Mechanical Engineering Design: Tenth Edition." McGraw-Hill Education, 2020.

American Bearing Manufacturers Association. "Load Ratings and Fatigue Life for Ball Bearings." ABMA Standards, 2018.

International Organization for Standardization. "Rolling Bearings - Dynamic Load Ratings and Rating Life." ISO 281:2017.

Khonsari, M.M. & Booser, E.R. "Applied Tribology: Bearing Design and Lubrication: Third Edition." John Wiley & Sons, 2017.

Hamrock, B.J., Schmid, S.R. & Jacobson, B.O. "Fundamentals of Machine Elements: Fourth Edition." McGraw-Hill Education, 2019.