One of the biggest problems with heavy machinery use around the world is that slewing ring bearings often break. These important parts can fail in a number of ways that have a very bad effect on equipment performance and the cost of doing business. They allow 360-degree rotation while holding very heavy loads. People who work in procurement, engineering, or maintenance in industries from wind energy to heavy machinery making must understand these patterns of failure and know how to stop them from happening. If you choose the right bearings and take care of them, they can work reliably for decades. But if you don't take care of them or use them wrong, they can fail in a very dramatic way, costing hundreds of thousands of dollars in repair costs and lost time.

Understanding Common Slewing Ring Bearing Failures

To catch bearing failures early, you need to know the failure modes and warning signs that occur in machines with rotation. Changes in operational behavior, such as higher noise levels, vibration patterns, or trouble getting exactly the right position, are things that equipment workers often notice first. These signs usually mean there are problems that can be fixed quickly to avoid total bearing failure and costly emergency repairs.

Primary Failure Types and Their Symptoms

Wear and abrasion are the most common causes of failure, especially when big loads or dirty environments are involved. This breakdown shows up as bigger clearances between rolling elements and raceways. This makes it harder to place things correctly and makes the system vibrate more. The 50Mn and 42CrMo materials used to make modern bearings resist wear very well, but this process can still be sped up by extreme circumstances.

Corrosion failures are hard to deal with, especially in marine and offshore uses where salt spray and humidity make the environment harsher. These failures usually start at seal surfaces. Moisture then gets into the bearing housing, slowly damaging the GCr15 bearing steel and making the structure weaker. Better seal materials, like nitrile rubber and fluororubber, offer more safety against these environmental issues.

Fatigue cracking happens slowly over time as the material is repeatedly stressed. These stress concentrations finally spread through the bearing material. This failure mode is especially bad for wind turbines because they have changing loading patterns and long operational times. Modern bearing designs use modern metallurgy and heat treatment methods to make them more fatigue resistant and extend their service lives.

Lubrication-Related Failures

Lubrication loss is another important way that bearing performance and lifespan are negatively affected. When there isn't enough lubricant, the rolling elements and raceways touch each other, which causes a lot of heat and speeds up the wearing process. On the other hand, too much lubrication can make parts turn against each other, which makes heat and lowers the performance of the machine.

Very high or low temperatures make lubrication harder, especially in metallurgical uses where the temperature is above 150°C. Specialized high-temperature lubricants and new seal designs help keep the grease in place even when conditions are tough.

Analyzing Causes and Failure Mechanisms

Engineering teams can keep equipment working well by learning about the root causes of slewing ring bearing failures so they can use targeted prevention methods. Failures related to load usually happen because the wrong bearings are chosen or the machine has to deal with unexpected demands that are beyond what it was designed to handle. In these cases, stress builds up, which speeds up the fatigue process and greatly shortens bearing life.

Load Distribution and Stress Analysis

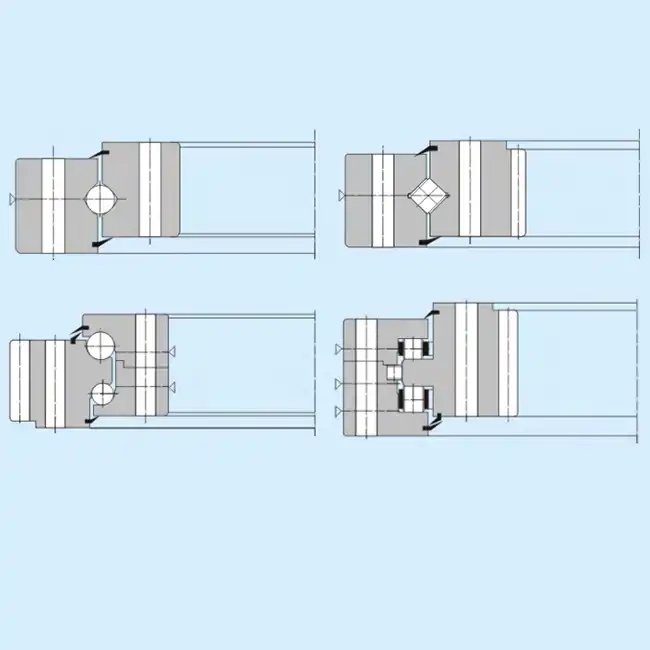

During the operational cycle, both static and dynamic loading factors must be taken into account during proper load analysis. While dynamic loads change when the equipment moves or when outside forces are applied, static loads stay the same. When choosing bearings for wind turbine yaw systems, crane rotation mechanisms, and excavator swing motors, the complicated ways that loads are applied must be carefully considered.

Hotspots that speed up localized wear are often caused by uneven load distribution, which happens when installation mistakes or structure misalignment occur. To get the best performance, modern bearing designs with outer rings between 100mm and 4000mm need to spread the weight across all of the rollers.

Environmental Impact Factors

The performance and failure rates of bearings in different situations are greatly affected by the environment. Systems that are meant to be sealed can still get dust and other particles in them, which creates rough conditions that make things run down faster. Mining and building have specific problems with airborne pollutants that make lubrication less effective.

When moisture gets in, it causes corrosion that attacks bearing materials and lubrication at the same time. When you work with port machinery and offshore equipment in salt spray settings, you need to use specialized protective measures and better sealing systems to keep them from rusting.

Proven Strategies to Prevent Slewing Ring Bearing Failures

To avoid failures, procurement, engineering, and support teams must work together to solve possible problems before they affect operations. Successful prevention programs use the right bearings, install them correctly, and make sure they are always working properly, all based on the needs of the business.

Maintenance Program Development

Regularly checking bearings is an important part of keeping them in good shape. Before bearings fail, visual checks can find early signs of seal breakdown, lubricant contamination, or mounting bolt loosening. Vibration monitoring gives you numerical data about the state of the bearing that lets you look for patterns and predict how long it will be useful for.

Key things to check are the accuracy of the dimensions, the level of flexibility in the slewing, and the noise made by the rolling elements. These factors give information about the health of the bearing. This helps maintenance teams plan ahead for when they need to fix something during scheduled downtime instead of having to fix something that breaks unexpectedly.

Installation Best Practices

Proper installation greatly affects how well the slew ring bearing works and how long it lasts during its entire operational lifecycle. Precision alignment makes sure that the load is spread evenly across all rolling parts. This stops stress from building up in one area, which speeds up the fatigue process. To keep the right preload without putting too much stress on the bearing structure, bolt torque specifications must be followed carefully.

Preparing the surface and keeping it clean during installation stop dirt from getting into the bearings and affecting their performance right from the start. Clean places where parts are put together and correct ways of treating them keep the bearing surfaces and lubricants safe from harm during installation.

Technical Insights – Slewing Ring Bearing Specifications and Monitoring

Modern bearing technology incorporates advanced materials and manufacturing processes that enhance performance across demanding applications. Understanding these technical specifications enables procurement teams to select optimal Solutions for specific operational requirements while ensuring compatibility with existing equipment systems.

Material Selection and Performance Characteristics

Contemporary bearing construction utilizes high-performance materials engineered for specific applications. The inner and outer rings typically employ 50Mn or 42CrMo alloy steels, providing excellent strength and durability under heavy loading conditions. Rolling elements use GCr15 bearing steel for standard applications, with GCr15SiMn available for enhanced impact resistance in demanding environments.

Seal material selection depends on operational requirements, with nitrile rubber providing general-purpose protection and fluororubber offering enhanced oil and high-temperature resistance. These material choices directly impact bearing performance and service life across different applications.

Advanced Monitoring Technologies

Predictive maintenance technologies enable early detection of bearing degradation before failures impact operations. Vibration analysis identifies changes in bearing dynamics that indicate developing problems, while thermal imaging detects temperature variations that suggest lubrication issues or excessive loading conditions.

Noise monitoring systems can detect changes in rolling element behavior that precede visible wear patterns. These technologies provide quantitative data that supports maintenance decision-making and optimizes intervention timing.

INNO Bearing Solutions for Industrial Applications

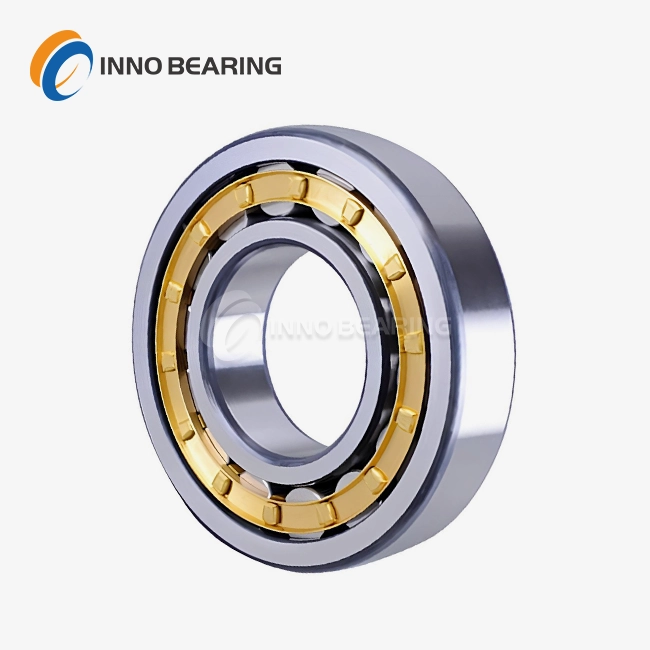

INNO Bearing specializes in manufacturing high-performance rotating bearings designed for demanding industrial applications across multiple sectors. Our extensive product range includes both ball-type and roller-type configurations, enabling equipment to achieve 360-degree rotation while supporting complex compound loads effectively.

Our manufacturing capabilities accommodate bearing sizes from 100mm to 4000mm outer ring diameter, with inner diameters ranging from 80mm to 3800mm and heights from 8mm to 150mm. This comprehensive size range ensures compatibility with diverse equipment types, from compact machine tools to massive wind turbine assemblies.

Quality Assurance and Testing

Every slew ring bearing undergoes rigorous testing procedures to verify dimensional accuracy, operational smoothness, and noise characteristics before delivery. Our quality management system ensures consistent performance across all products, supporting equipment reliability and minimizing operational disruptions.

Advanced testing equipment validates bearing performance under simulated operational conditions, confirming load capacity, fatigue resistance, and environmental protection capabilities. These comprehensive validation procedures provide confidence in bearing performance across challenging applications.

Conclusion

A deep knowledge of failure mechanisms, proper selection criteria, and strict upkeep routines are all necessary to keep bearing failures from happening. Organizations that buy good bearings, put them correctly, and check them often find that their equipment lasts much longer and their costs go down. Using advanced materials, exact manufacturing, and good maintenance plans together makes sure that even the most difficult industrial tasks run smoothly. The buying, engineering, and maintenance teams must work together to make sure the right bearings are chosen and the lifecycle is managed properly in order to reach the goals.

FAQs

What are the most common causes of premature bearing failure?

The primary causes include inadequate lubrication, contamination from dust or moisture, improper installation leading to misalignment, and operating loads exceeding design specifications. Environmental factors such as extreme temperatures and corrosive conditions also contribute significantly to premature failures.

How often should rotating bearings be inspected and maintained?

Inspection frequency depends on application severity and operational conditions. High-load applications typically require monthly visual inspections and quarterly detailed assessments, while lighter-duty applications may extend intervals to quarterly visual checks and semi-annual comprehensive evaluations.

What factors should be considered when upgrading to heavier-duty bearings?

Key considerations include load capacity requirements, environmental conditions, space constraints, mounting interface compatibility, and expected service life. Material selection, seal type, and lubrication requirements must also align with operational demands and maintenance capabilities.

Partner with INNO Bearing for Superior Reliability Solutions

INNO Bearing delivers exceptional rotating bearing solutions engineered to meet the demanding requirements of modern industrial applications. Our experienced engineering team provides comprehensive technical support throughout the selection, installation, and maintenance lifecycle, ensuring optimal performance and extended service life. With nearly 30 years of manufacturing expertise and advanced testing capabilities, we understand the critical importance of bearing reliability in maintaining operational efficiency. Whether you need standard configurations or custom solutions for unique applications, our team stands ready to provide the technical expertise and manufacturing capabilities your projects demand. Contact Us at sales@inno-bearing.com to discuss your slewing ring bearing requirements with our experienced technical specialists.

References

Harris, T.A. & Kotzalas, M.N. "Essential Concepts of Bearing Technology: Rolling Bearing Analysis, Fifth Edition." CRC Press, 2007.

Eschmann, P., Hasbargen, L. & Weigand, K. "Ball and Roller Bearings: Theory, Design and Application." John Wiley & Sons, 1999.

Shipley, E.E. "Analysis of Bearing Failures in Industrial Machinery." ASME Journal of Engineering for Industry, Vol. 89, No. 4, 1967.

Tallian, T.E. "Failure Atlas for Hertz Contact Machine Elements." ASME Press, 1992.

Nelias, D. & Dumont, M.L. "Analysis of Rolling Element Bearing Vibrations and Failure Mechanisms." Journal of Sound and Vibration, Vol. 248, No. 5, 2001.

ISO 15243:2017 "Rolling bearings – Damage and failures – Terms, characteristics and causes." International Organization for Standardization, 2017.