One of the most costly and disruptive problems in industrial operations is the failure of Thrust ball bearings. In fact, breakdowns caused by bearings make up about 30% of all rotating machinery failures. These important parts are made to handle axial loads going in one or two directions through single-row or double-row steel ball structures. When they fail, they can stop production lines, break costly tools, and make workers less safe in industries ranging from heavy machinery to wind energy.

Introduction

Thrust ball bearings are important parts that help keep many types of machinery running smoothly, even when they are used in tough industrial settings. They do this by supporting axial loads. Bearing failures can have many different causes. Procurement specialists, engineers, and OEM clients in aerospace defense, mining, port engineering, heavy machinery, and wind energy need to know what these are so they can choose bearings wisely and keep them in good shape.

This all-in-one guide talks about common ways things can go wrong, how to compare performance and find the best ways to avoid problems that have a direct effect on operational efficiency. By outlining these important points, we want to help people in the global industrial sector increase equipment uptime, lower maintenance costs, and choose the best axial load bearings for their specific needs. The effects of bearing failure go beyond just replacing the part. It can lead to system failures that cost companies thousands of dollars per hour because they aren't productive.

Understanding Thrust Ball Bearing Failures

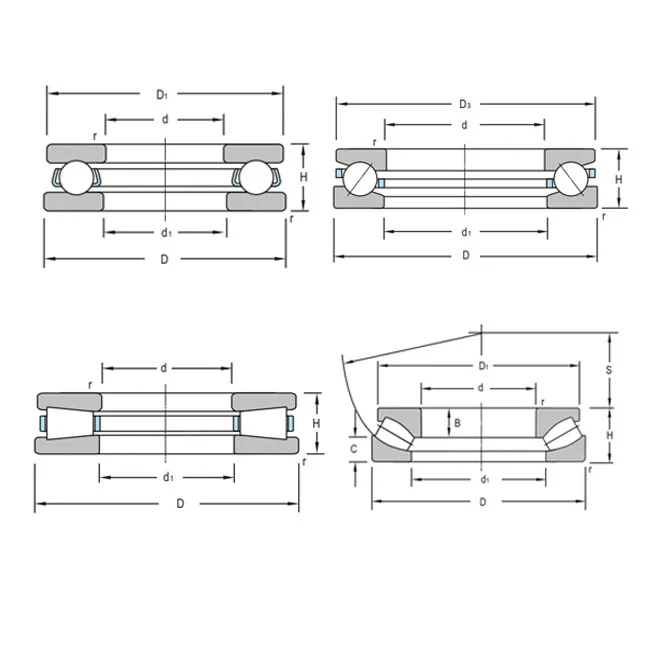

These specialized bearings work by allowing parts that are rotating to move along axial loads. They are usually used in cars, aerospace, wind turbines, and heavy machinery. Their design includes steel balls that are precisely made and put between the shaft and housing washers. Cages keep the balls separate so they can roll smoothly even when big forces are pushing along their axes.

Effect on Factory Work

The effects of bearing failure go beyond just having to replace the part right away. It causes a lot of other problems in the industrial operations that are affected. Unplanned outages can stop whole production lines, and emergency repairs usually need replacement parts that cost a lot and workers to work extra hours. In wind energy applications, turbines can be offline for days while waiting for special bearing replacements. This equipment downtime directly affects the money made from generating power and promises of grid stability.

Important Factors for Performance

Thrust bearings used today must work in tougher conditions. In normal uses, the temperature ranges from −40°C to over 150°C. For heavy-duty applications, load capacities can reach up to 200 kN, and rotational speeds depend on the needs of the application. Understanding these operational parameters helps procurement teams choose the right bearing Solutions that fit the way they will actually be used instead of based on imagined maximums.

Top 5 Common Causes of Thrust Ball Bearing Failure

Thrust ball bearings break for reasons that can be predicted and avoided if procurement teams and maintenance engineers follow the right steps for choosing, installing, and maintaining them. You can make plans that avoid costly problems and lengthen the lifetime of your equipment if you know how things can go wrong.

Misalignment and poor installation

The most common installation mistake that leads to early bearing failure is misalignment, which causes an uneven load distribution across rolling elements. Carefully ground surfaces can be damaged if you don't mount things correctly. Also, if you install something and use tools the wrong way, you can make little stress spots that turn into fatigue cracks. During installation, it is important to remember that expansion due to temperature can change the clearances and how the load is spread.

Environmental Pollution and Factors

When lubricants mix with dust, moisture, chemicals, and other things, they don't work as well. This also increases the wear rate between rolling elements and raceways. Marine environments are especially hard on things because the salt spray and humidity make corrosion happen faster. Mining applications use bearings with rough particles that grind away at them, changing the shape of surfaces and load distribution.

Putting a Lot of Extra Weight on It

Going past the design load limits makes parts of the bearing bend right away or develop fatigue damage over time. Static overloads can cause raceways to get permanent dents, and dynamic overloads make fatigue cracks start faster. Shock loading happens a lot when using heavy machines. It causes stress levels to rise above the yield strength of the material, which makes the structure less strong.

Quality Issues and Material Fatigue

The way bearings resist fatigue and wear depends a lot on the material they are made of. Alloys made with standard grades don't last as long as those made with high-quality steels like GCr15 and GCr15SIMN. The fatigue life is directly changed by heat treatment processes, which alter a material's hardness and the way residual stress is spread over it. Quality control during manufacturing makes sure that the properties of the materials and how well they fit together are always the same. This stops failure modes from happening too soon.

Lack of maintenance and lubrication

About 40% of all bearing breakdowns could be avoided if bearings were properly lubricated (the right amount and type of lubricant are used and the lubrication system is kept clean). The lubricant's molecules are broken down by extremely high and low temperatures, and oxidation creates acidic compounds that wear down the bearings' surfaces. If you don't keep up with maintenance, early warning signs such as odd noises, higher temperatures, or changing vibration patterns will turn into complete failures.

Comparing Thrust Ball Bearing Failure with Other Bearing Types

When failure mode analysis shows big differences between axial load bearings and other designs, procurement teams can pick the best options for different uses. These differences change the way things are maintained and replaced, as well as the way the total cost of ownership is calculated.

How to Handle Axial and Radial Loads: The Differences

Roller bearings usually deal with higher radial loads by using line contact between the parts that roll and the raceways. This alters the way they fail in comparison to thrust bearings that are optimized for point contact axial loads. Spherical roller thrust bearings handle misalignment better than ball thrust bearings, but they lose some of their load capacity and ability to rotate quickly. While Angular contact ball bearings are able to handle combined loads, they are more difficult to install and need to be mounted on surfaces that are more precise.

When Picking Between Single and Double Direction Design, Things to Keep in Mind

Unidirectional thrust bearings with shaft washers, housing washers, and single-row steel balls face different kinds of stress than bidirectional ones with intermediate washers and double-row setups. Single-direction bearings tend to last longer when the load direction doesn't change. But they will break quickly if the load direction changes. Two-way designs are more flexible, but they require more complicated systems for lubrication and exact clearance adjustments.

Sealed and Open Levels of Bearing Protection

It's common for sealed bearings to fail less often than open designs because they keep dirt and grease out more effectively. Non-contact seals don't seal as well, but they do create less friction and heat. Contact seals create more friction and heat, but are better at keeping out contamination. Open bearings lose heat more easily and can be relubricated more easily, but they need more care and protection from the environment.

Best Practices to Prevent Thrust Ball Bearing Failure

To avoid failures, it is important to choose the right person, install correctly, lubricate well, and monitor proactively. These methods make sure that procurement investments give the most value by making the service life longer and the reliability better.

Strategic Choice and Specification

When choosing bearings, the speed range, load size, temperature, and environment for each application must be taken into account. For standard uses, P0/P6 are okay, but for high-speed or very important uses, P5 is better. Engineering teams should make sure to use the right accuracy grades. Choosing between common steel grades and specialized alloys depends on how much temperature and corrosion resistance you need, as well as how long you expect the material to last.

Exact Methods for Installation and Mounting

Installation must be done exactly as the manufacturer says, using the right tools and methods to keep precision surfaces from getting damaged. Installation methods that control temperature make sure that parts fit correctly without causing thermal stress. Bearing performance and lifespan are directly affected by the preparation of the shaft and housing. This includes checking the surface finish and measuring accuracy. Following the correct torque specs and steps for sequential tightening will stop uneven stress distribution and mounting distortion.

High-Tech Systems for Keeping an Eye on Conditions

Vibration and thermal imaging and oil analysis are used in modern condition monitoring to find early signs of failure before a huge breakdown happens. Vibration signatures show developing problems in rolling parts, raceways, and cages. At the same time, temperature monitoring shows lubrication breakdown and rising friction. Ultrasonic monitoring picks up high-frequency sounds from micro-fractures and surface asperity contact. These sounds happen before any visible signs of failure.

About INNO Bearing: Premium Thrust Ball Bearing Solutions

Thrust ball bearings are what Luoyang INNO Bearing Co., Ltd. does best. Their high-quality bearings are made for businesses around the world, including OEMs and distributors in the aerospace sector as well as wind energy, mining, heavy machinery, and port engineering. We have almost 30 years of experience in the industry, and we use both advanced material science and precision manufacturing to make parts that can handle the toughest conditions.

A wide range of products

Our thrust ball bearings come in both unidirectional and bidirectional designs. In their standard forms, they have inner diameters from 10mm to 300mm and outer diameters from 30mm to 400mm. For special uses, custom solutions with an outer diameter of up to φ5000 mm are available. For raceways and rolling elements, high-grade GCr15, GCr15SIMN, and 20Cr2Ni4A steel alloys are available. Stamped steel or brass cage materials are used for specific operating conditions.

Quality Testing and Assurance

Every bearing is put through a lot of different tests to make sure it will work in real-life conditions. These tests include lifespan simulation, vibration analysis, and thermal cycling. Spectrometer analysis is used in material inspections to make sure that the alloys are consistent. At the same time, precision grinding gets raceway tolerances of ≤0.001 mm. Our quality control systems ensure that 99.9% of products have no defects, from checking the raw materials to the end packaging and delivery.

The world's supply chain and support services

Regional warehouses in Europe, Asia, and North America make it easy to get more than 1,000 standard bearing models quickly, and they can deliver in 48 hours if needed. The average time for custom bearing solutions is 30% slower than the rest of the industry. This is because design and manufacturing processes have been made more efficient. Comprehensive technical support includes looking at things before installation, predictive maintenance programs, and getting help with technical issues any time of the day or night to get the best performance from bearings and stop them from failing too soon.

Conclusion

Thrust ball bearings fail for a number of reasons. To proactively keep downtime to a minimum, procurement and maintenance teams must understand these failure modes.tIndustrial operations can make sure that equipment is reliable and bearings last longer by dealing with root causes with the right choice of bearings, correct installation, and goodlIn tough industrial settings, buying quality bearings and regularly maintaining equipment always pays off by increasing uptime, lowering the need for emergency repairs, and improving overall efficiency.

FAQs

What are the first signs of thrust ball bearing failure?

Grinding, squealing, hotter-than-usual working temperatures, higher vibration levels that can be seen through condition monitoring, and dirty lubricants are early signs. Things usually go wrong when the temperature is 10–15 degrees Celsius above normal. However, vibration analysis can detect issues weeks before they sound.

How can I tell if lubricant or device installation is the problem?

Lubrication failure wears raceways and rolling parts. This usually means the lubricant has broken down or accumulated dirt. Poor installation causes uneven wear, high stress, or uneven damage, indicating mounting or misalignment issues. Maintenance history and wear patterns can complete the diagnosis.

Are ceramic hybrid bearings worth the extra money for hard field work?

At temperatures above 150°C, ceramic hybrid bearings outperform all-steel bearings. They're less corroding and farther apart. Even though they cost more, ceramic balls last longer, require less care, and use less energy, making them better for tough conditions. This benefit usually justifies the higher cost in hard times.

Partner with INNO Bearing for Superior Thrust Ball Bearing Solutions

INNO Bearing's precisely designed thrust ball bearing solutions will help you get the most out of your equipment's reliability and operational efficiency. We are a top thrust ball bearing manufacturer with almost thirty years of experience. We make custom bearings that can handle the most difficult tasks. Our high-tech materials, exact manufacturing, and thorough testing make sure that performance is better and service life is longer in wind energy, heavy machinery, mining, and aerospace applications.

Our technical team is here to help you every step of the way, from choosing the right bearings to installing them and keeping them in good shape. This helps you avoid expensive mistakes and get the best performance from your bearings. INNO Bearing helps your business run smoothly by offering over 1,000 standard models and custom solutions that are 30% faster than the industry standard. To talk about your exact needs and learn how our high-quality thrust ball bearings can make your operations more reliable, email us at sales@inno-bearing.com.

References

1. Harris, T.A. and Kotzalas, M.N. "Essential Concepts of Bearing Technology: Rolling Bearing Analysis, Fifth Edition." CRC Press, 2007.

2. Eschmann, P., Hasbargen, L. and Weigand, K. "Ball and Roller Bearings: Theory, Design and Application, Second Edition." John Wiley & Sons, 1985.

3. Tallian, T.E. "Failure Atlas for Hertz Contact Machine Elements, Second Edition." American Society of Mechanical Engineers, 1999.

4. Palmgren, A. "Ball and Roller Bearing Engineering, Third Edition." SKF Industries Inc., 1959.

5. Hamrock, B.J., Schmid, S.R. and Jacobson, B.O. "Fundamentals of Fluid Film Lubrication, Second Edition." Marcel Dekker Inc., 2004.

6. ISO 15243:2017 "Rolling Bearings - Damage and Failures - Terms, Characteristics and Causes." International Organization for Standardization, 2017.