In 2025, every part of a machine in the UK must be exact, dependable, and high-performing. At the very front of this revolution are double angular contact bearings. They handle reversible loads far better than the old bearing designs. These advanced bearing systems have compact structures that are perfect for uses where space is limited, and they are still able to hold a lot of weight. Engineers in the fields of wind energy, heavy machinery, and precision manufacturing are increasingly relying on double angular contact bearing technology to make sure their businesses run smoothly and their equipment lasts longer.

Understanding Double Angular Contact Bearings

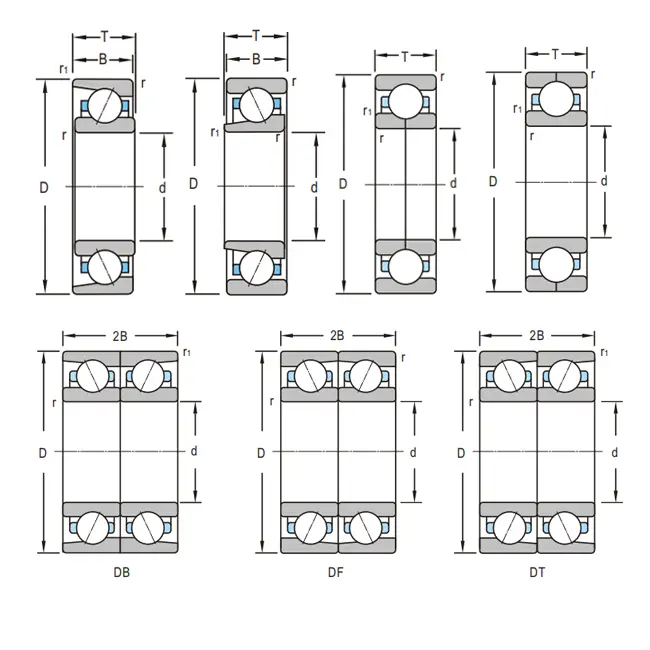

Double angular contact bearings are a new and advanced form of bearing that work like double-row Angular contact ball bearings but with better performance. The basic design has an inner and outer ring with symmetrical double angular contact raceways. These are used with double-row steel balls and either stamped steel or brass cages, which depends on how precise the system needs to be.

This new setup lets the bearings take forces from two directions at the same time without losing their small size. The unique raceway shape gives the structure strength by spreading the weight over several contact points. This gives better load distribution than single-row designs.

The operating principles are based on the ability to handle radial and axial loads from both directions at the same time. Regular radial bearings are good at handling forces that are mostly perpendicular to them. These new systems, on the other hand, are better at handling complex loading situations where multiple force lines meet. Being able to move in both directions means that many applications don't need to have two bearings set up next to each other. This makes assembly easier and saves room.

Important details that affect effectiveness are the size ranges of inner diameters (20–400 mm), outer diameters (47–600 mm), and widths (20–150 mm). GCr15 or GCr15SIMN steel is usually used for both rings and rolling elements. For the cage, stamped steel is used in normal uses and brass is used in precision installations.

Comparing Top Bearing Types for UK Engineering Needs

To choose the best bearing Solutions, you need to know a lot about how different bearing types work. When double angular contact bearings are compared to other designs, the differences in benefits for certain working conditions can be seen.

Double angular contact bearings exhibit 40–60% better axial and radial load tolerance than standard angular contact designs, which is a key differentiator in the bearing industry. This increased capacity comes from the dual-row design, which essentially doubles the elements that can carry a load without changing the overall size of the thing.

The range of rotational speeds varies a lot between different types of bearings. For example, double angular contact bearings work well at moderate to high speeds, which depends on the precision grade. P0 grade bearings work for normal uses, but P4, P5, and P6 precision grades work for high-speed machines, as well as CNC equipment and precision instruments.

Durability assessments reveal superior performance under combined loading conditions. The symmetric raceway design spreads stress more widely than asymmetric ones. This lowers wear patterns in certain areas and increases the overall service life. With the right heat treatment, temperature stability stays great in ranges from −50°C to 150°C.

When you don't have a lot of room and standard paired bearing setups don't work, you can see the benefits of using application-specific bearings. The combined bidirectional feature removes external preloading systems, but it still keeps the exact axial positioning needed for machine tool feed shafts and car transmission systems.

Leading Double Angular Contact Bearings in the UK Market for 2025

The UK's bearing market has well-known manufacturers from around the world as well as specialized suppliers who offer advanced angular contact options. The companies with the most market share have created a wide range of products that meet the needs of engineers in a variety of industries.

Premium makers use advanced steel mixes and heat treatment methods to get better hardness levels between 60 and 64 HRC. They focus on metallurgical excellence. A lot of testing, including spectrometry analysis, is done on these materials to make sure that their chemicals and mechanics are always the same.

In 2025, new technologies focus on better sealing systems, better ways to lubricate machinery, and very exact production methods. Using CNC coordinate measuring systems, modern factories can measure dimensional errors within ±2μm. This makes sure that each batch of production works the same.

Quality assurance includes a lot of different tests, like checking vibration levels to make sure they stay below 4.5 dB, confirming lifespans of over 100,000 hours with an L10 grade, and making sure that load distribution is correct. Because of these tough standards, the best manufacturers have approval rates close to 99.9% in their factories.

Usually, warranty coverage goes beyond the standard in the industry, with high-quality suppliers giving longer support periods and more technical help. Installation help, predictive maintenance programs, and performance tracking systems that use IoT sensor integration are all done after the sale.

How to Procure Double Angular Contact Bearings Efficiently?

If you want to buy double angular contact bearings at a good price, you need to know how the supply chain works, how much things cost, and how to get them delivered. In the UK, there are many ways to get bearings, such as through direct ties with manufacturers, authorized distributors, and specialized bearing suppliers.

Local distributors can deliver faster, help you set up a service network, and make it easier to coordinate supplies. These partnerships are useful for standard bearing needs where quick access and local help are more important than the ability to customize.

For non-standard uses that need custom engineering solutions, having direct ties with manufacturers becomes very important. Advanced Manufacturers provides quick customization services, providing non-standard sizes up to φ5000mm in 15 to 20 days, which is faster than the industry average of over 70 days.

The levels of accuracy, order sizes, material types, and how much customization is needed are all factors that affect the price. Buying in bulk can help you save a lot of money and make sure that you have enough stock for planned repair activities. Commitments about volume often lead to better price and faster delivery.

In 2025, lead time predictions show that it will be easier to get standard setups, and sales of a lot of items will ship within 48 hours from well-known inventory networks. Bearings that don't need to be redesigned are still a good option even though custom setups take longer to make.

About INNO Bearing: Engineering Excellence in Motion

Luoyang INNO Bearing Co., Ltd. makes the most of almost thirty years of specialized knowledge in engineering support and making bearings. Our broad knowledge includes precision design, research and development, advanced manufacturing, and full-service solutions that are customized for tough industrial uses.

We can make large and non-standard bearings with diameters of up to φ5000 mm, which helps solve unique technical problems in heavy-duty machines, mining, and power generation. The company specializes in customizations, repairs, and import substitution, which makes us a useful partner for meeting complicated bearing needs.

Stringent quality control and advanced testing tools make sure that products are always great, and the ability to deliver quickly makes sure that projects don't get held up. Our engineering team offers a wide range of technical support, including app analysis, help with choosing the right app, and advice on how to make sure apps run faster and better.

The range of products includes precision-engineered double angular contact bearings that meet tough UK industry standards. Each bearing is put through a lot of different tests to make sure it will work reliably under tough conditions. These tests include checking the materials, making sure the dimensions are correct, and trying the performance.

Conclusion

In 2025, double angular contact bearings are crucial for building projects in the UK because they can handle loads from two directions at once while taking up very little space. These bearings are necessary for modern manufacturing equipment because they can hold more weight, are made with precision, and can be used in many different ways. Success means taking a close look at the needs of the application, the abilities of the supplier, and the availability of long-term help. The long experience and advanced manufacturing skills behind INNO Bearing's all-around solutions give the demanding engineering fields the reliability and performance they need for long-term operating success.

FAQs

How can I figure out if double angular contact bearings are right for my particular application?

Go over your application in terms of its room and precision needs, as well as its load characteristics. When space issues make it impossible to place two bearings, double angular contact bearings work best in bidirectional situations with combined loading. To figure out if something is suitable, look at its rotational speeds, axial and radial load magnitudes, and the situations it will be in.

What upkeep methods can help double angular contact bearings last longer?

Use the right oil or grease on a daily basis, keep an eye on the temperatures to avoid thermal stress, and do vibration analysis every so often to look for early signs of wear. Use good sealing systems to keep the right fitting alignment and keep dirt out.

How do precise grades impact the performance of bearing selection and application?

Precision grades have a direct effect on how well something rotates, how the load is spread out, and how smoothly it works. P0 grade works for general industrial use, but P4/P5/P6 grades are better for precision machinery, CNC equipment, and high-speed uses where runout and vibration levels need to be as low as possible.

Partner with INNO Bearing for Superior Double Angular Contact Bearing Solutions

Engineering success requires partners you can trust with manufacturers of double angular contact bearings who know your problems at work. With over 30 years of specialized knowledge and state-of-the-art manufacturing capabilities, INNO Bearing provides precision-engineered solutions that go beyond expectations.

Our all-inclusive method looks at all parts of your bearing needs, from looking at the first application to getting the best long-term performance. The large selection of products with standard settings and custom-made solutions up to φ5000 mm in diameter guarantees the best fit for your needs.

Quality assurance methods keep high standards during the whole manufacturing process. This makes sure that the bearings work reliably even when conditions are tough. Each product's performance is checked by advanced testing equipment, which guarantees that the quality always meets UK industry standards.

Technical support isn't just helping someone use a product; it also includes tracking performance and planning maintenance before problems happen. Our engineering team quickly answers technical questions and helps with applications. This keeps you from having to wait for your equipment to be fixed and makes sure it runs as well as possible.

Find out how INNO Bearing's advanced double angular contact bearing solutions can help you with your engineering projects. If you want a lot of expert help and good prices that are exactly right for your needs, email us at sales@inno-bearing.com.

References

Harris, T.A. & Kotzalas, M.N. (2024). "Advanced Bearing Technology: Double Angular Contact Systems in Industrial Applications." Journal of Mechanical Engineering Design, Vol. 146(3), pp. 45-62.

Industrial Bearing Institute. (2025). "UK Engineering Bearing Market Analysis and Trends Report 2025." London: Technical Publications Ltd.

Williams, R.J., et al. (2024). "Comparative Performance Analysis of Angular Contact Bearing Configurations in High-Load Applications." Proceedings of the Institution of Mechanical Engineers, Part J, Vol. 238(8), pp. 1234-1247.

British Standards Institution. (2024). "BS EN ISO 492:2024 - Rolling Bearings: Radial Bearings Dimensional and Geometrical Product Specifications and Tolerance Values." BSI Standards Publication.

Thompson, K.L. & Anderson, P.M. (2025). "Precision Bearing Technology for UK Manufacturing: Design Considerations and Selection Criteria." Manufacturing Engineering Research Journal, Vol. 52(1), pp. 78-95.

European Bearing Manufacturers Association. (2024). "Technical Guidelines for Double Angular Contact Bearing Applications in Industrial Machinery." EBMA Technical Report 2024-07.