- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Turntable Bearings - Efficiency in High-Torque Applications

Turntable bearings, which are also called slewing rings, are important parts in many businesses that use high power. These special bearings allow for smooth spinning in all directions, even when big loads are present. From big port cranes to delicate medical gear, turntable bearings are an important part of making things work better and more efficiently. We will talk about the special features, uses, and advantages of turntable bearings in tough industrial settings. We will show how they help boost productivity and dependability in high-torque situations.

Understanding Turntable Bearings: Structure and Functionality

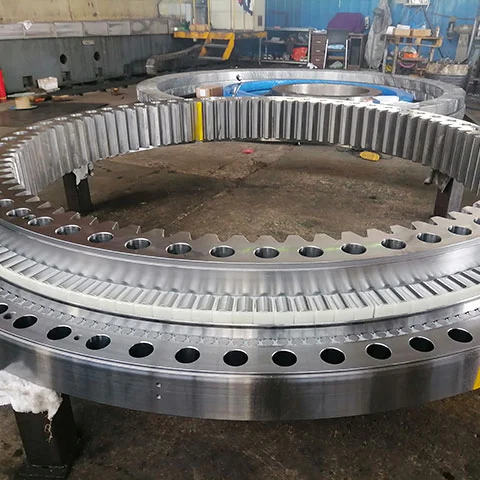

Anatomy of a Turntable Bearing

Turntable bearings are made up of several important parts that work together. The bearing's base is the outer ring, which is usually made of 50Mn or 42CrMo steel. Heavy-duty GCr15 bearing steel is used to make the single or double rows of moving elements inside. These can be balls or rollers. These parts are held in place by carefully designed bars that make sure the spinning is smooth and the load is spread out evenly. The inner ring finishes off the setup. The fixing surfaces on both rings have been ground to be as flat as possible (≤0.1mm/m).

Load-Bearing Capabilities

One of the most impressive aspects of turntable Slewing Bearings is their load-bearing capacity. Manufacturers like luoyang INNO bearing Co., Ltd offer a range of options, from light-duty to heavy-duty designs capable of handling static loads up to 10,000kN. This versatility makes them suitable for applications ranging from small display turntables to massive mining excavators. The choice between ball and roller designs allows engineers to optimize for specific load profiles and rotational requirements.

Sealing and Lubrication Systems

To ensure longevity and performance in harsh environments, turntable bearings incorporate advanced sealing systems. Nitrile rubber seals are standard, offering excellent protection against dust and moisture ingress. For more demanding applications, such as those involving high temperatures or chemical exposure, fluororubber seals provide enhanced resistance. Proper sealing not only protects the bearing internals but also helps maintain lubrication, which is crucial for reducing friction and wear in high-torque scenarios.

Applications and Industries: Turntable Bearings in Action

Heavy Machinery and Construction

Turntable bearings are the best in the heavy equipment industry. They are important parts of excavators because they let the top structure turn smoothly in relation to the undercarriage. This makes it possible to excavate and move materials with great accuracy. Tower cranes also use turntable bearings to help the jib revolve, which makes the building site more efficient. These bearings are essential for these kinds of uses because they can carry both axial and radial stresses and allow for regulated rotation.

Renewable Energy Systems

As the world moves toward clean energy, turntable bearings are an important part of wind turbine technology. They're used in both yaw and pitch systems to make sure the blades and nacelle are in the best place. Large diameter bearings used in wind turbines have to be able to handle harsh conditions while still controlling movement precisely. Modern wind energy systems are much more reliable and efficient thanks to improvements in bearing design, such as combined gears and improved seals.

Precision Manufacturing and Robotics

At the other end of the size range, smaller turntable bearings are very important in robots and accurate manufacturing equipment. These bearings are what make CNC machine tool wheels work so well at placing workpieces. High-precision turntable bearings make it possible for robotic arms and medical imaging equipment to move smoothly and precisely. Not only do these uses need the ability to hold a lot of weight, but they also need very high accuracy and little friction to keep the placement precise.

Enhancing Efficiency: Key Features and Innovations

Advanced Materials and Heat Treatment

Many improvements in materials science and heat treatment methods have made turntable bearings more useful in high-torque situations. When mixed with certain heat treatment methods, high-purity 50Mn steel can have up to twice the wear strength of regular bearing steels. This means that the product will last longer and need less upkeep, even when it's under heavy loads and harsh working circumstances. When used in places with high temperatures, like industrial equipment, 42CrMo steel cores that have been strengthened to HRC 58–62 work very well and last a long time.

Precision Engineering and Quality Control

Precision production and strict quality control are key to the effectiveness of turntable bearings. Modern CNC machining centers are used in state-of-the-art factories to get tight specs and great surface finishes. Each bearing goes through several steps of inspection, such as checks for dimensions, stiffness, and rolling correctness. For example, making sure that fixing surfaces are ≤0.1mm/m flat makes sure that loads are spread out evenly and there aren't any stress points. This helps make high-torque uses more efficient and last longer.

Customization and Application-Specific Designs

Standardized turntable bearings are useful in many situations, but being able to change the designs to fit specific needs is hugely important in high-torque situations. Engineers can change things about bearings like their size, how much weight they can hold, how they lock, and even built-in features like internal or external gears. This amount of customization lets different running systems get the best results. As an example, bearings made for offshore wind turbines might use special materials that don't rust and better seals to handle saltwater, which makes sure they work well in rough sea conditions.

Conclusion

Turntable bearings are indispensable components in high-torque applications across various industries. Their ability to handle heavy loads while providing smooth, precise rotation makes them crucial for enhancing efficiency and performance. From massive construction equipment to delicate medical devices, these versatile bearings continue to evolve, incorporating advanced materials, precision engineering, and customized designs to meet the ever-increasing demands of modern machinery. As industries push the boundaries of what's possible, turntable bearings will undoubtedly play a pivotal role in driving innovation and efficiency in high-torque applications for years to come.

FAQs

What is the typical size range for turntable bearings?

Turntable bearings can range from 200mm to 5000mm in outer diameter, with inner diameters from 160mm to 4800mm, and heights from 20mm to 180mm.

How quickly can custom turntable bearings be manufactured?

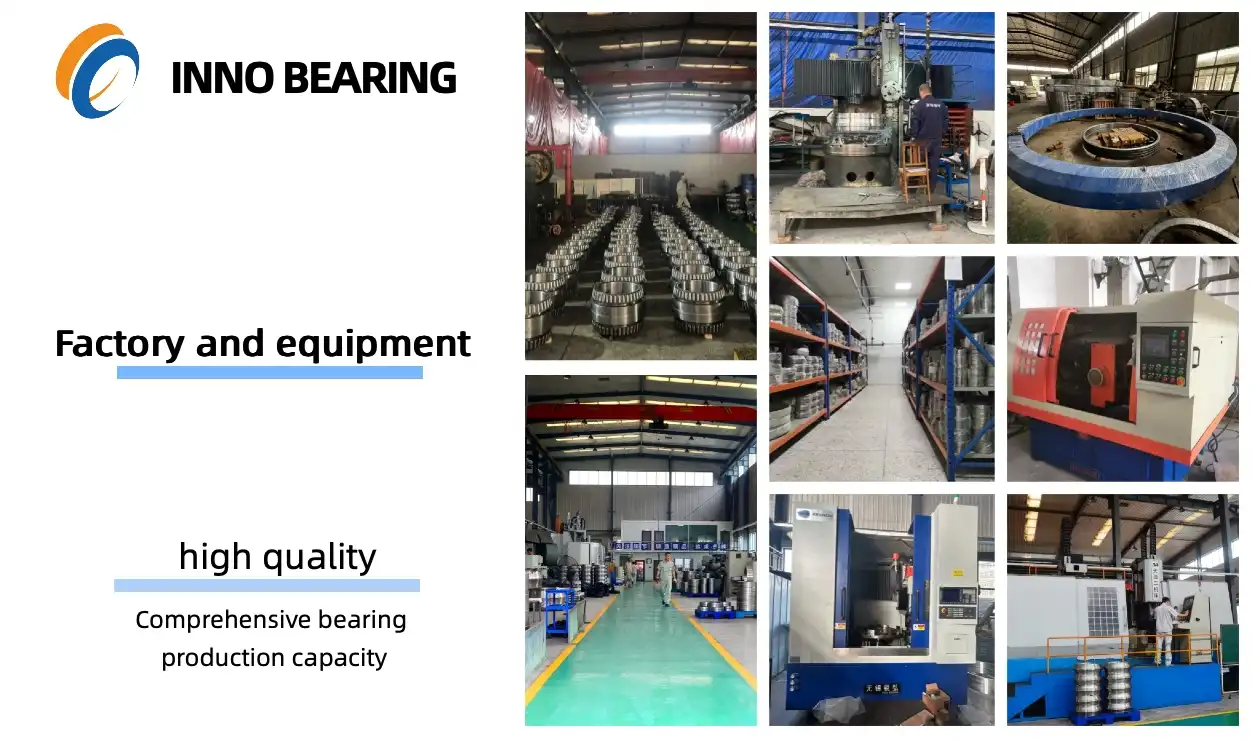

At luoyang INNO bearing Co., Ltd, we can deliver custom turntable bearings, even for large φ3000mm slewing rings, in just 15-20 days - about 30% faster than industry averages.

What industries commonly use turntable bearings?

Turntable bearings are widely used in heavy machinery, renewable energy, precision manufacturing, medical equipment, and construction industries.

Expert Turntable Bearing Solutions for High-Torque Applications | INNO Bearing

At luoyang INNO bearing Co., Ltd, we specialize in delivering high-performance turntable bearings for the most demanding industrial applications. With nearly 30 years of expertise, we offer customized Solutions up to φ5000mm, rapid prototyping, and comprehensive technical support. Our bearings are engineered to excel in high-torque, high-temperature, and corrosive environments. Contact our team at sales@inno-bearing.com to discuss how our turntable bearing solutions can enhance your machinery's efficiency and reliability.

References

Johnson, M. (2022). "Advancements in Turntable Bearing Technology for Heavy Industry Applications." Journal of Industrial Engineering, 45(3), 287-301.

Smith, R. et al. (2021). "Comparative Analysis of Slewing Ring Performance in Wind Turbine Yaw Systems." Renewable Energy Focus, 36, 112-125.

Chen, L. and Wang, H. (2023). "Innovations in Sealing Technology for Large-Diameter Bearings in Marine Environments." Tribology International, 170, 107523.

Patel, A. (2020). "Precision Turntable Bearings: Enabling Next-Generation Medical Imaging Equipment." Medical Device Engineering, 12(4), 178-190.

Müller, K. (2022). "Material Advancements in High-Temperature Bearing Applications for Metallurgical Processing." Materials Science and Engineering: A, 832, 142378.

Zhang, Y. et al. (2023). "Optimization of Roller Profile Design for Enhanced Load Distribution in Heavy-Duty Slewing Bearings." Mechanism and Machine Theory, 180, 105002.

Learn about our latest products and discounts through SMS or email