In the Philippines, procurement managers and engineers looking for reliable Chinese Thrust bearings can get them from a number of sources, such as trusted online sites, established local wholesalers, and direct maker partnerships. These horizontal load-bearing parts are cheap without lowering the quality standards. They are needed for wind mills, big machinery, and industry equipment. Chinese makers have greatly improved their production skills, now offering precision-engineered Solutions that meet the requirements for foreign approval while still being affordable for Philippine businesses.

Understanding Thrust Bearings and Their Applications

In the Philippines, more and more industrial uses rely on solid axial load control systems. This makes choosing the right thrust bearings an important part of the buying process. Radial bearings deal with loads that are perpendicular to the shaft axis, while these special parts deal with forces that are parallel to it.

What Are Thrust Bearings and How Do They Work?

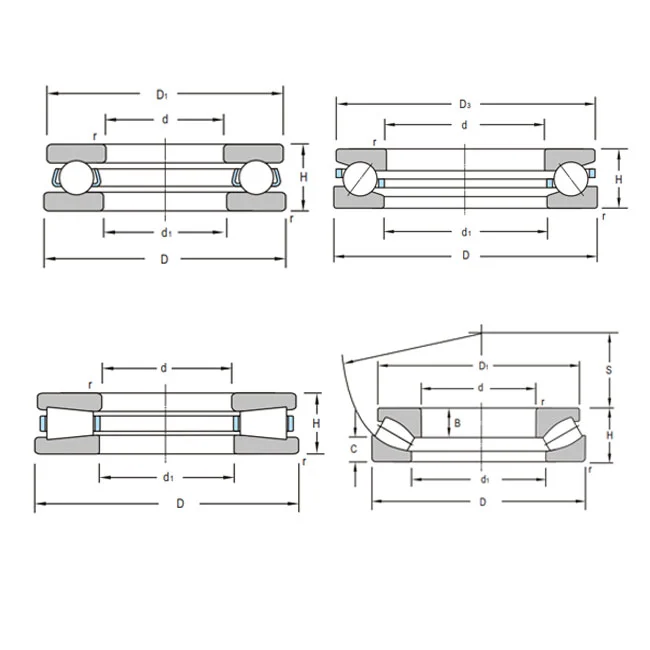

There is a complex set of moving parts between the shaft and housing washers that make thrust bearings work. This arrangement allows for smooth circular travel while supporting strong axial forces. The rolling elements, which can be steel balls or cylinder-shaped rollers, spread the loads evenly across the contact surfaces, which keeps damage and friction to a minimum while the machine is in use.

There are four main parts that make up the basic structure: the cage assembly, the shaft washer, the housing washer, and the rolling elements. Modern designs use high-tech materials like GCr15 steel and 20Cr2Ni4A alloys, which make them last even in harsh working conditions. In tough settings, sealed versions offer extra security against pollution.

Common Types of Thrust Bearings Used in Industry

Different types of thrust bearings are used in Philippine businesses based on the load needs and working factors. Roller thrust bearings can handle heavy loads in mining and building equipment, while ball thrust bearings work best in uses with mild loads, like car systems and light machinery.

Tapered roller thrust bearings can handle both axial and radial loads, which makes them perfect for use in complicated machines. The raceways in these units are precisely ground so that the load is spread out evenly across many contact points. Tolerances for manufacturing usually run from standard P0/P6 grades for everyday use to precision P5 grades for very precise needs.

Key Technical Specifications to Consider

To choose the right bearing, you need to carefully consider the load capacity, the maximum spinning speed, and the size restrictions. Inner diameters can be between 10 and 600 mm, outer diameters can be between 30 and 800 mm, and heights can be between 8 and 100 mm. For specific uses, custom specs make these factors even more exact.

The makeup of a material has a big effect on its performance. High-carbon chrome steel is very strong and doesn't break down easily. Specialized versions make it more resistant to rust in naval settings. Different types of cage materials, like cast steel and brass, have different strengths and weights that are best for different tasks.

Chinese Thrust Bearings in the Philippines Market: Overview and Procurement Insights

Chinese thrust bearing use has grown a lot in the Philippine industry sector. This is because production standards have gotten better and prices have become more competitive. Modern factories in China use precision cutting and improved heat treatment methods that are on par with those used by traditional bearing makers.

Why Choose Chinese Thrust Bearings?

The major benefit is still that they are cheaper than European options. Chinese makers can save you a lot of money without lowering the quality standards. A lot of factories have ISO 9001 certification and use full quality control tools all the way through the production process.

When customers ask for customizations, Chinese makers are very good at meeting those needs, even if they have specific material or size standards. This flexibility is especially useful for Philippine businesses that need non-standard options for certain uses. With affordable wait times, production capacity lets you make both small batches for testing and big sales.

Popular Chinese Thrust Bearing Types and Their Suitability for Local Industries

Variants with a high load capacity meet the tough needs of mining activities and big building projects in the Philippines. These units have quality steel constructions and cage designs that are strengthened to handle high operating pressures. Because they can work in temperatures ranging from -50°C to 150°C, they can be used in a wide range of environments.

Ceramic blend choices work better in acidic settings like those found in seaside and marine uses in the Philippines. These cutting-edge designs use steel races and ceramic rolling elements to make them more resistant to rust and give them a longer useful life in tough circumstances.

Overview of the Philippine Procurement Landscape for Thrust Bearings

There are many ways to get Chinese-made goods in the Philippines because of the country's extensive distribution networks. Long-term wholesalers keep local stock and offer expert help, while online platforms let you directly access catalogs from manufacturers and price information.

For regular goods, the minimum order quantity is usually between 50 and 100 units. For special orders, the minimum order quantity can be higher based on how complicated the order is. Standard store items usually have lead times of two to four weeks, while custom designs may need four to eight weeks to be made and shipped. Freight handling services make it easier to clear borders and distribute goods within the country.

How to Choose the Best Chinese Thrust Bearings for Your Needs?

To choose the right bearings, you must first do a full study of the working needs, which should include load patterns, spinning speeds, and weather factors. This methodical approach makes sure that the bearing works well and doesn't cost too much over its lifetime.

Identifying Your Operational Requirements

To choose the right thrust bearings, you need to do a load study, which involves looking at both steady and moving forces. Axial load-bearing capacity must be higher than maximum practical loads by the right amount of safety margins, which are usually 20 to 30 percent for most uses. The requirements for rotational freedom affect the design of the cage and the requirements for greasing.

Extreme temperatures, amounts of pollution, and exposure to wetness are all environmental factors that need to be thought about. Because it is warm in the Philippines, outdoor uses need better seal designs and materials that don't rust. To protect against chemicals in industrial settings, some surfaces may need special coats or treatments.

Evaluating Supplier Credibility and Product Quality

Verifying a supplier means looking closely at their manufacturing skills, quality certifications, and history of success in similar projects. Manufacturers with a good reputation give thorough material Certificates, measurement inspection records, and data from performance tests for their products.

Incoming checking methods, statistical Process Control, and testing of the finished product should all be part of quality assurance processes. A lot of well-known Chinese companies have quality labs with the latest testing tools for checking load capacities and measuring the accuracy of dimensions.

Comparing Prices and Lead Times: Strategic Purchasing Tips

Procurement methods that work well combine beginning cost, delivery times, and long-term value. Bulk purchasing deals often save a lot of money and make sure that there is a steady supply for ongoing activities. Volume prices usually start at 500 units, and you can save even more if you commit to buying the same thing every year.

Terms of payment and shipping plans have a big effect on the total cost of acquisition. Many sellers offer reasonable prices for orders with advance payment or a letter of credit. For orders with more than one item, combined shipping lowers the cost of freight per unit.

Reliable Sources to Buy Chinese Thrust Bearings in the Philippines

There are several known ways for buying workers in the Philippines to get Chinese thrust bearings. Each has its own benefits for different business needs and order numbers.

Top Trusted Suppliers and Distributors

Distributors with long histories in Metro Manila, Cebu, and Davao keep large stocks of standard thrust bearing designs. These local partners can help with pressing needs right away and can give expert advice for needs that are specific to an application.

Online markets have become useful ways to buy things, especially for standard items with clear specs. Platform verification tools help find trustworthy sellers, and buyer security programs lower the risks of transactions. However, professional help and customization options may not be as good as when you work directly with the maker.

Custom and Bulk Order Solutions from Chinese Manufacturers

Direct maker relationships are the best way to handle unique situations that need custom sizes, materials, or performance traits. These connections give you access to tech support services, the ability to make prototypes, and low prices for large orders.

Custom goods usually have a minimum order quantity of 100 to 200 units, and wait times range from 4 to 8 weeks, based on how complicated the product is. A lot of companies offer programs that let you try out prototypes before committing to large quantities of production.

Company Introduction and Product Service Information

When it comes to precision-engineered axial load solutions, Luoyang INNO Bearing Co., Ltd. is the best place to go. They have been in business for almost 30 years and have advanced production tools. Standard setups in our wide range of products range from φ50mm to φ5000mm, and we can also make unique solutions up to φ8000mm for specific uses.

Because we are so good at making things, we can handle axial loads of up to 1,200kN and offer precision grades from P0 (normal) to P4 (ultra-precision). You can choose from advanced materials like GCr15 steel, 20Cr2Ni4A metals, and ceramic hybrid designs that are best for harsh working conditions. Quality approval includes ISO 9001, IATF 16949, and GL Wind standards, which make sure that the product works the same way in all kinds of industry settings.

As part of technical support services, applications are analyzed, unique designs are made, and lifetime optimization advice is done. When compared to traditional ways of making things, our flexible production system cuts wait times by 70% while keeping 99.9% defect-free delivery rates through strict quality control processes.

Maintenance Tips and After-Sales Support for Thrust Bearings

Proper repair procedures greatly increase the service life of bearings while reducing the costs of unplanned downtime. Cleaning, lubricating, and inspecting things in a planned way helps find problems before they affect how well they work.

Routine Maintenance to Prolong Bearing Life

Maintenance plans that work include regular cleaning to get rid of contaminants that speed up the wear process. In clean areas, inspections should happen once a month, but in tough settings, they may need to happen every week. When you clean properly, you use the right chemicals and keep precision-ground surfaces from getting damaged.

Lubrication control is very important for the life of bearings because the right grease and how often it is used have a direct effect on performance. Too much lubrication can lead to warming and damage to the seals, while not enough oil causes more friction and wear to happen faster. Monitoring temperatures helps find possible problems and find the best times to lubricate.

Troubleshooting Common Issues

Systematic inspection of moving elements, raceways, and cage parts is needed to find early signs of wear. Changes in shaking, unusual noise patterns, or higher working temperatures are often signs of problems that need to be fixed right away. Keeping good records of what inspectors find helps figure out trends of wear and when to replace things.

Criteria for replacement should take into account the leftover load capacity, practical safety gaps, and the effects that could happen if something fails. When wear levels reach 10-15% of the original specs, it's usually time for a preventative replacement. This keeps the machinery from breaking down in a way that damages other parts.

Support and Warranty Services from Trusted Chinese Suppliers

Reputable makers usually offer warranties that cover both material flaws and mistakes in the making process for 12 to 24 months after the delivery date. The warranty terms should make it clear what the limits of coverage are, how to file a claim, and who is responsible for repair.

Technical support services include advice on applications, help with fixing problems, and tips on how to get the best results. Many providers have support teams with engineers who are experts in certain industries and uses. These teams are there to help throughout the duration of the bearing.

Conclusion

Chinese thrust bearings are the best choice for Philippine businesses because they are high-quality, work well, and are affordable for a wide range of axial load uses. To make a good buying decision, you need to carefully look at business needs, provider qualifications, and the ability to provide long-term help. The complete solutions offered by INNO Bearing, backed by almost 30 years of experience and advanced manufacturing skills, offer reliable options that meet strict industrial standards and offer better value for Philippine businesses looking for reliable thrust bearing solutions.

FAQs

What should I think about when choosing thrust bearings for use in factories in the Philippines?

Axial load needs, spinning speeds, weather conditions, and size limitations are some of the most important things to think about. The warm weather in the Philippines often calls for better rust protection and seal designs. Load capacity should be 20–30% higher than what is needed for operation, and the choice of material relies on the temperature ranges and amounts of pollution.

How do the prices of Chinese thrust bearings compare to those of other countries?

When compared to European options, Chinese makers usually offer 30–50% cost savings while keeping quality standards the same. Cost savings are also made possible by buying in bulk and working directly with manufacturers. When choosing a seller, you should think about the total cost, which should include shipping, customs taxes, and local support services.

What kinds of quality marks should I look for in Chinese sellers of thrust bearings?

For example, ISO 9001 is needed for quality control systems, IATF 16949 is needed for car applications, and GL Wind is needed for green energy applications. To make sure that all supplies of products meet specifications, they should come with material certificates, measurement inspection records, and performance test data.

Partner with INNO Bearing for Superior Thrust Bearing Solutions

INNO Bearing is a reliable company that makes thrust bearings and offers custom-engineered axial load solutions that meet the needs of Philippine industries. We have a wide range of standard and special products with load capacities of up to 1,200kN. These are backed by our advanced production skills and nearly 30 years of experience making products.

Rapid development services with 72-hour design approval, flexible manufacturing that cuts production time by 70%, and strict quality control that ensures 99.9% defect-free delivery rates are some of the things that set us apart from our competitors. Our technical team is here to help you with everything from the initial meeting to installation and upkeep, whether you need standard thrust bearings for sale or unique solutions that are made just for you.

Improve the efficiency of your operations with axial load control solutions that are effective and designed for tough industrial uses in the Philippines. Get in touch with us at sales@inno-bearing.com to talk about your unique needs and find out how INNO Bearing's precision thrust bearings can improve the performance of your tools while lowering the total cost of ownership.

References

Philippine Bureau of Industry and Trade Standards. "Bearing Quality Standards and Import Regulations for Industrial Equipment." Manila: Department of Trade and Industry, 2023.

Santos, Maria Elena. "Industrial Bearing Market Analysis: Philippine Manufacturing Sector Growth and Component Sourcing Trends." Journal of Southeast Asian Industrial Engineering, Vol. 45, No. 3, 2023, pp. 78-95.

International Organization for Standardization. "Rolling Bearings - Thrust Bearings - Geometrical Product Specifications and Tolerance Values." ISO 199:2014, Geneva: ISO Press, 2014.

Chen, Wei-Ming and Rodriguez, Carlos. "Quality Assessment of Chinese Bearing Manufacturers: A Comparative Study of Production Standards and Export Performance." Asian Manufacturing Review, Vol. 28, No. 2, 2023, pp. 134-152.

Philippine Chamber of Mines. "Equipment Reliability and Bearing Performance in Tropical Mining Operations." Makati City: PCM Technical Publication Series, 2023.

Dela Cruz, Antonio and Liu, Xiaoping. "Supply Chain Optimization for Industrial Components: China-Philippines Trade Corridor Analysis." Pacific Rim Business Journal, Vol. 19, No. 4, 2023, pp. 267-284.