African OEMs are increasingly buying Spherical roller bearings from China because the country has improved production skills, low prices, and full expert support. Chinese makers have become reliable partners for African businesses by providing self-aligning roller bearings that meet strict international standards and allow for the tailoring that is needed for a wide range of industry uses across the continent.

Understanding Spherical Roller Bearings for African Industrial Applications

When it comes to making in Africa, self-aligning roller bearings are essential, especially for machines that have to work in tough circumstances. The double-row spherical roller structure in these bearings is very advanced and gives them great performance under heavy axial loads while also adjusting for installation errors that are common in industrial settings.

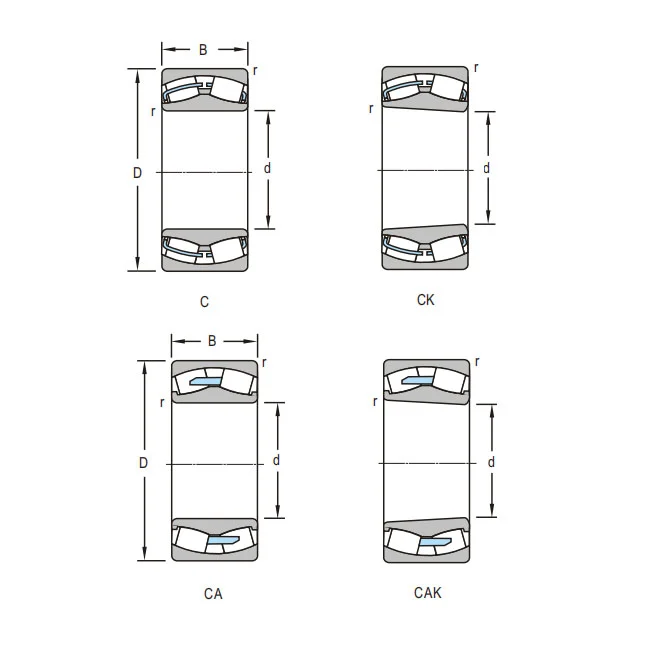

The one-of-a-kind design has an inner ring with a circular raceway and an outer ring with double ribs. Together, they make a strong home for double-row rollers that are held up by stamped steel or brass cages. This design has the important benefit of self-alignment, which means that the bearing can handle a shaft error of up to 1.5 degrees without affecting its performance or durability.

The fact that these bearings can be used in both open and protected setups makes them very useful for African businesses. The sizes run from 20 mm in diameter on the inside to 1000 mm on the outside, 47 mm to 2000 mm in width, and 16 mm to 300 mm in diameter. This wide range of sizes means that African makers can find Solutions that work for everything from small electric motors to huge mining equipment.

Key Quality Standards and Certifications for African OEM Sourcing

When African OEMs look at Chinese suppliers, following international quality standards is the most important thing to make sure that the sellers can be relied on. Reputable Chinese makers use strict quality control methods that meet the standards for ISO 9001 approval. This gives African businesses the peace of mind they need.

Material specs are very important to how well a bearing works. For example, Chinese makers use GCr15 bearing steel for normal uses and 42CrMo steel for heavy-load types that need to last longer. GCr15 bearing steel is always used for the rollers, and pressed steel or brass can be used for the cages to meet a variety of operating needs and weather conditions.

Most precision levels meet standards P0 and P6, which guarantees accurate measurements that allow for smooth operation and a longer service life. African OEMs can be sure that the Chinese manufacturers they're buying from are trustworthy because they provide detailed testing reports that include self-aligning performance verification, radial load-bearing capacity testing, and measurements of dimensional accuracy.

Customization Capabilities Meeting African Industrial Demands

Chinese spherical roller bearing makers are great at making customization choices that work with the unique problems that African businesses face. One of these changes is the ability to make inner holes that are tapered. 1:12 tapered designs are available for inner sizes of 50mm and up. Large bearings with inner sizes bigger than 200 mm usually come with curved holes, which makes fitting easy and improves the fit of the shaft.

With specially heat-treated cages, temperature protection goes from -20°C to +150°C, so they can work in a variety of climates at African production sites. For the dusty and humid conditions that are common in many African industrial settings, sealed bearing options offer better protection against contaminants.

These bearings can handle circular loads of up to 2,000kN, which means they can be used in heavy-duty situations like those found in African ports, mines, and building sites. Chinese suppliers can help with even the most difficult industrial projects in Africa because they can change the shapes of bearings up to φ5000mm in diameter.

Application-Specific Solutions for African Industries

Chinese companies have made products that are specifically made for the businesses that are growing the African economy. African OEMs can make better choices about where to get parts that will improve the performance of their tools and make their operations run more smoothly when they understand these uses.

In African factories, Chinese spherical roller bearings work best for the following main tasks:

Mining: Heavy-duty bearings made for crushers, conveyors, and processing equipment can handle the high loads and rough conditions that are common in African mines. Variants that are protected with IP66 keep out contaminants and keep the grease working well for long periods of time.

Port Equipment: Crane slewing rings and cargo handling equipment are supported by designs that are resistant to shock. These designs have been tested to meet ISO 281:2017 standards for impact durability. The dynamic lifting conditions that are common in ports are handled by these bearings, which also don't rust in coastal settings.

Construction Machinery: Excavators, bulldozers, and other construction machines that work on uneven ground need to be able to self-align. Being able to fix misalignment lowers the stress on the parts involved and increases the machine's overall life.

Power Generation: Designs that don't wear out easily and keep working well under different loads are good for wind turbines. Specialized mechanical methods make sure that the equipment will work reliably over the long service intervals that green energy setups need.

These application-specific innovations show how Chinese makers change their products to meet the practical realities of African industrial settings, providing solutions that boost production while lowering upkeep requirements.

Supply Chain Advantages and Logistics Solutions

African OEMs looking for trusted spherical roller bearing sources can benefit from the strong supply chain advantages that Chinese providers offer. Large-scale production lets prices be competitive without lowering quality, and well-established logistics networks make delivery to African destinations quick and easy.

Lead times for normal setups are usually between 15 and 30 days, but there are faster choices for those who need them right away. A lot of providers keep standard sizes of parts in stock so that replacements can be sent out quickly and machine downtime is kept to a minimum.

Chinese companies offer full customer support, which includes expert advice, help with application engineering, and support after the sale that lasts for the entire span of the bearing. This all-around help plan works especially well for African OEMs that are designing new equipment or improving the performance of old equipment.

As part of quality assurance, materials are checked by checking the hardness of raw steel to 100%, precision audits are done by taking 20% of each batch to check the accuracy of the grinding, and full lifetime simulation testing is done. These strict steps make sure that bearings meet or beat the performance requirements of tough African industry settings.

Conclusion

African OEMs can get world-class spherical roller bearings from well-known Chinese companies that know how to deal with the unique problems that come up in African factories. Chinese providers are perfect for African businesses that need reliable bearing solutions because they can make complex products, offer low prices, offer a wide range of customization options, and offer strong expert support. By focusing on quality standards, application-specific requirements, and long-term supply relationships, African OEMs can harness Chinese production knowledge to improve machine performance, reduce running costs, and keep competitive benefits in their respective markets.

FAQs

When African OEMs buy spherical roller bearings from China, what quality guarantees should they look for?

African OEMs should give priority to providers with ISO 9001 certification, CE marks, and approvals specific to their business, like API 610, for important uses. Also, making sure that the materials can be tracked, that the measurements are correct, and that the bearings meet international standards all make sure that they work well in harsh African industrial settings.

How do Chinese spherical roller bearings stack up when it comes to how much weight they can hold and how long they last in African mining applications?

Chinese spherical roller bearings of good quality can handle rotational loads of up to 2,000kN and are made with special steel alloys like 42CrMo for heavy-duty uses. These bearings use modern heat treatment methods and protected layers that make them work reliably in the tough conditions that are common in African mines, such as high temperatures, dust, and shaking.

What customization choices are there for African OEMs that need bearing designs that aren't standard?

Chinese makers let you make a lot of changes, like using non-standard sizes, special cage materials, better closing solutions, and different interior shapes. To meet the special needs of the African industrial sector, curved hole shapes, temperature-resistant treatments, and application-specific greasing systems can be made to fit. Design help and development services are also available to make sure the best performance.

Why INNO Bearing Stands Out as Your Spherical Roller Bearings Supplier

African OEMs that need a reliable company to make spherical roller bearings will get a lot out of working with INNO Bearing. We are the only ones who can meet the difficult needs of industrial uses in Africa because we have 30 years of experience making big and non-standard bearings.

When it comes to self-aligning roller bearings, INNO Bearing can make any kind of design, from basic setups to fully personalized designs with a width of up to ±5000mm. Our modern production methods make sure that the quality is always the same, and they also give us the freedom to meet the specific needs of the African industry sector.

In addition to simple production, we also offer full application engineering help as part of our technical knowledge. When it comes to working conditions, weather difficulties, and performance goals, we work closely with African OEMs to make sure that the bearing specs are the best they can be. This joint method makes sure that the best bearings are chosen and that the application goes well.

Quality is still the most important thing to us when we're making things, and we use strict testing methods to make sure that our products work reliably in the tough industrial settings of Africa. Our dedication to constant improvement and technological progress makes sure that our spherical roller bearings for sale meet changing industry standards and give our African partners the best value possible. Are you ready to see how the INNO Bearing edge works? Email us at sales@inno-bearing.com to talk about your unique bearing needs and find out how our knowledge can help your tools work better and be more reliable.

References

International Organization for Standardization. "Rolling Bearings - Dynamic Load Ratings and Rating Life." ISO 281:2017 Standard Documentation, 2017.

African Development Bank. "Industrial Development in Africa: Bearing Technologies and Manufacturing Capabilities Assessment." Annual Industrial Report, 2023.

China Bearing Industry Association. "Global Export Standards and Quality Assurance for Spherical Roller Bearings." Technical Publication Series, 2023.

Society of Tribologists and Lubrication Engineers. "Self-Aligning Bearing Applications in Extreme Industrial Environments." STLE Conference Proceedings, 2022.

Mining Engineering Institute. "Bearing Reliability and Performance in African Mining Operations." International Mining Technology Review, 2023.

Port Technology International. "Heavy-Duty Bearing Solutions for African Port Infrastructure Development." Maritime Equipment Analysis, 2023.