Spanish wholesalers are increasingly choosing Chinese Thrust bearings because they have a great cost-performance ratio, can make improved products, and have a dependable supply chain infrastructure. These axial load-bearing parts are reasonably priced without lowering the quality standards. They meet strict European certifications and can be customized to fit a wide range of industry needs. Chinese manufacturers are the best choice for Spanish distributors in many areas, such as renewable energy, heavy machinery, and offshore engineering. This is because they are always coming up with new technologies, can make products in a variety of ways, and offer full after-sales support.

Understanding Thrust Bearings and Their Market Demand in Spain

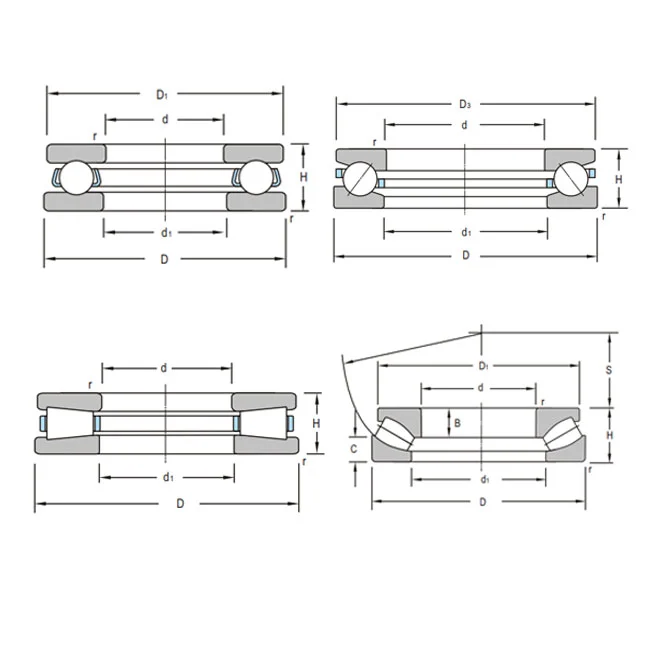

Thrust bearings are special kinds of mechanical parts that are made to support axial loads and make spinning motion smooth in a wide range of industry settings. These precision-engineered gadgets include shaft washers, housing washers, rolling elements (steel balls or rollers), and cages. The cages come in both open and sealed versions to protect the environment better.

There is a rising need for these important parts in Spain's industries, especially in facilities for green energy, the production of big machinery, and port operations. Spain's plan to increase its use of green energy has opened up a lot of business possibilities for bearing providers. This is because wind turbine sites need very reliable axial support systems for the main shafts, yaw systems, and pitch control mechanisms.

Industrial wholesalers all over Spain are under more and more pressure to meet European safety standards while also lowering costs and meeting quality standards. The problems go beyond just choosing what to buy; they also include making choices about the stability of the supply chain, the availability of expert help, and long-term repair, all of which have a direct effect on how efficiently operations run.

What Are Thrust Bearings and How Do They Work?

Thrust bearings work by spreading axial forces across carefully designed contact surfaces. This stops metal-on-metal friction, which would otherwise wear down equipment quickly and cause it to break. For tough jobs, the basic structure is made of high-quality materials like GCr15 steel, GCr15SiMN alloys, and special 20Cr2Ni4A mixtures.

Inner sizes of modern thrust bearings can be anywhere from 10 mm to 600 mm, while outer diameters can go up to 800 mm and heights can be anywhere from 8 mm to 100 mm. This ability to change dimensions lets it be used in a wide range of industries, from high-precision machine tools that need to be P5-accurate to heavy-duty mining equipment that has to work under very heavy loads.

Current Demand Trends for Thrust Bearings Among Spanish Distributors

Spanish wholesalers say that projects to update infrastructure and automate factories are driving up demand for axial bearing Solutions. Excavators, trench boring machines, and crane systems all need strong vertical support mechanisms, so the construction machinery industry as a whole has a lot of room to grow.

A study of the market shows that wholesalers give more weight to sellers who can offer detailed technical documents, the ability to track materials, and quick response times for both standard and unique setups. The complex needs of modern industrial processes are reflected in this trend. When technology breaks down, businesses lose money.

Comparative Advantages of Chinese Thrust Bearings for Spanish Distributors

By strategically investing in new manufacturing technologies and quality control methods, Chinese companies have changed the thrust bearing business in a big way. These developments enable production of high-performance axial bearings that consistently meet international standards while maintaining competitive pricing structures beneficial to Spanish distributors.

China's manufacturing climate supports both ball thrust bearings, which are best for light loads, and roller thrust bearings, which are made for heavy-duty industrial settings. This variety makes sure that Spanish dealers can find the right products for a wide range of uses, from car turning systems to huge crane slewing rings, without sacrificing performance standards.

Chinese providers are very good at making sealed thrust bearings with IP69K protection, which is necessary for the tough working conditions typical in Spanish marine and mine uses. When you combine advanced sealing technologies with precision-ground bearing surfaces, you get goods that work well in corrosive environments and are still reliable.

Cost-Performance Balance: Why Chinese Bearings Offer Competitive Pricing Without Compromising Quality

Chinese thrust bearings are cheaper because they are made more efficiently, economies of scale work in their favor, and they strategically source their raw materials, not because they skimp on quality. Modern factories in China use computer-controlled heat treatment methods and automatic precise cutting tools to make sure that the material qualities and sizes stay the same.

Chinese providers can cut wait times by up to 70% compared to old ways of doing things by using flexible manufacturing systems to make production more efficient. They still have to meet strict quality control standards, though. Because they are more efficient, they save money on costs, which helps Spanish wholesalers make more money and offer low prices to end users.

Quality and Material Standards: Meeting International and European Certifications

Chinese makers of thrust bearings follow strict certification programs that include ISO 9001, IATF 16949, and the more specific GL Wind Certification for use in green energy uses. These awards show that a company is dedicated to quality management systems that meet or go beyond European industry norms.

Material tracking programs use spectrometry to make sure that all raw steel is 100% pure, and precise production methods get defect-free rates of more than 99.9%. These quality control methods give Spanish dealers faith that the product will work reliably and consistently in a range of situations.

Technological Innovation and Variety in Chinese Thrust Bearing Designs

Chinese thrust bearing technology keeps getting better thanks to new ideas. Manufacturers are coming up with unique solutions for tough working conditions. When ZrN-coated rollers are paired with improved polymer seals, they work very well in marine settings and have been tested to last over 1,000 hours of salt spray exposure.

Adding IoT-enabled tracking features is a big step forward in technology. It makes it possible to use proactive maintenance strategies that cut down on machine downtime by up to 30%. Chinese providers are now at the head of Industry 4.0 developments thanks to these kinds of new ideas. They give Spanish wholesalers cutting-edge solutions for their industrial customers.

Key Factors Influencing Spain Distributors' Preference for Chinese Thrust Bearings

When Spanish wholesalers work with Chinese thrust bearing suppliers, they see a lot of benefits, especially when it comes to the stability of the supply chain and the freedom of the manufacturing process. China's strong industrial infrastructure allows for steady production even when global demand is high. This means that Spanish wholesalers can keep the inventory levels they need to provide quick customer service.

Chinese makers take a joint approach that goes beyond just supplying products. It includes full technical help and engineering advice. With this partnership approach, Spanish distributors can give their customers services that add value, such as custom bearing design, application engineering, and installation help. These services improve relationships with customers and help the distributors place itself in the market.

Reliable Supply Chains and Flexible Lead Times

Chinese companies that make thrust bearings use complex supply chains that keep disruptions to a minimum by using a variety of buying methods and smart inventory management. Being able to stick to regular production plans even when there are problems in the global supply chain gives Spanish wholesalers reliable delivery dates that are needed for planning projects and keeping customers happy.

Many Chinese providers offer faster production plans for important uses, and their flexible manufacturing skills let them respond quickly to urgent needs. This ability to quickly respond is very helpful for Spanish wholesalers when their industrial customers need urgent replacements or sudden rises in demand.

Customized Solutions and OEM Collaboration Opportunities

Chinese companies are great at making thrust bearings that are exactly what an application needs. They work closely with Spanish dealers to make sure that the goods they sell meet specific performance standards. This way of working together includes OEM agreements, where the specs of bearings can be made better for certain types of equipment or running situations.

Chinese sellers offer engineering help in the form of detailed CAD modeling, finite element analysis, and performance simulation services that let Spanish wholesalers give their customers high-tech solutions. These skills set these wholesalers apart in competitive markets and make sure that bearings work well in tough situations.

After-Sales Service and Warranty Support

Chinese makers have faith in their goods, as shown by their extensive guarantee programs and after-sales support services. These services also give Spanish wholesalers an edge in their home markets. Customers will be happy and stay with you for a long time if you offer extended warranties and respond quickly to performance problems.

Spanish wholesalers offer more value to their customers through technical support services like online tests, fixing help, and maintenance training programs. This amount of help makes thrust bearings last longer while keeping end users' operations running as smoothly as possible.

Addressing Common Concerns: Quality, Durability, and Compatibility

When you compare the performance of Chinese thrust bearings to well-known global names, you can see that they are typically more reliable and work better. Independent testing shows that the expected service life is about the same under the same working conditions. However, measures of the noise level often go above what is considered acceptable for precision uses.

When choosing bearings, it's important to think carefully about the important difference between thrust bearings and rotational bearings to get the best performance and life. Chinese makers offer detailed application advice and technical paperwork to help with choosing the right bearings and installing them correctly.

Thrust Bearing Durability and Noise Level Comparison: Chinese vs. Global Brands

Chinese makers put their products through a lot of tests, such as earthquake analysis, rapid life testing, and noise level measures that compare their claims of performance to foreign standards. When made correctly, Chinese thrust bearings regularly have service lives that are on par with top global brands and often have better noise qualities.

Advanced mechanical methods used in heat treatment processes make sure that all bearing parts have the best material qualities. This helps them last longer and work the same way under different load situations. These improvements in making have taken away worries about quality from the past while keeping price benefits.

Differences Between Thrust and Radial Bearings: Ensuring Correct Application

Knowing the basic differences between axial and radial load usage helps you avoid expensive mistakes that could cause bearings to fail early or not work as well as they should. Chinese sellers give Spanish wholesalers thorough application guides and tech help so that they can give their customers good advice.

When choosing the right bearing, you need to think about things like the load size, the spinning speed, the working temperature, and the weather conditions that can affect how well the bearing works and how long it lasts. Technical consulting services help wholesalers make the best bearing choices for each job while avoiding common mistakes in the selection process.

Maintenance Tips and Measuring Wear on Chinese Thrust Bearings

Systematic tracking and preventative care methods are used in maintenance programs that work to increase the life of bearings and reduce unplanned downtime. Chinese makers give detailed upkeep instructions that include when to lubricate, how to measure wear, and how to keep an eye on performance.

Wear measurement tools and methods allow early discovery of bearing degradation before it leads to catastrophic failure. This lets repair activities be planned in a way that keeps operations running as smoothly as possible. Spanish wholesalers can teach their customers how to properly maintain bearings so that they work as well and as reliably as possible with the help of training programs.

Procurement Best Practices for Spanish Distributors Buying Chinese Thrust Bearings

To have good purchasing relationships with Chinese providers, you need to carefully check out their manufacturing skills, quality certifications, and past performance records, among other things. Setting up clear seller approval methods that check for technical know-how, financial security, and customer service skills is good for Spanish wholesalers.

Spanish wholesalers can get the best deals on supplies while also making sure they are always available by using strategic buying methods that include volume promises, flexible payment terms, and joint planning. These actions improve ties with suppliers and give businesses in the area an edge in the local market.

How to Choose the Best Chinese Thrust Bearing Supplier?

As part of evaluating a supplier, facilities should be inspected, quality systems should be looked at, and references from current customers should be contacted to confirm the claimed skills and performance standards. Virtual tours of facilities and thorough presentations of capabilities give possible providers' manufacturing processes and quality control measures more information.

A supplier's financial health is checked to make sure they can stay in business in the long run, and their technical skill is checked to make sure they can meet specific product standards and delivery promises. Full seller approval lowers the risks of buying while setting the stage for long-term relationships that work well.

Bulk Purchase Options, Pricing Negotiations, and Shipping Logistics

Buying in bulk can save you a lot of money through economies of scale, and it also makes sure you have enough supplies to give great customer service. Spanish wholesalers and Chinese sellers can both benefit from negotiation strategies such as long-term promises, flexible delivery plans, and flexible payment terms.

Shipping logistics optimization through combined packages, efficient customs processes, and smart warehouse placement lowers the total cost of buying things and makes sure that they are available on time. By learning about the rules and paperwork needed for foreign trade, you can avoid delays and extra costs that affect the overall cost of buying.

Leveraging Technology Platforms for Purchase and Inquiry

Digital B2B sites make it easier to communicate and buy things, and they give you access to more suppliers and information about low prices. These tools make it easier to have expert conversations, compare quotes, handle orders, and keep full records of all transactions.

Integration of technology allows for automatic control of supplies, forecasts of demand, and monitoring of seller performance, all of which improve the ease of buying and the ability to make decisions. When Spanish wholesalers use these tools, they get a competitive edge because they make their operations more efficient and help customers more quickly.

Conclusion

The fact that Spanish wholesalers prefer Chinese thrust bearings shows that market needs and provider skills are strategically aligned in a way that goes far beyond cost. Chinese makers are a good long-term partner for Spanish industrial wholesalers because they use advanced manufacturing technologies, have thorough quality systems, and can make products to fit specific needs. Distributors will continue to choose Chinese thrust bearings because they are reliable, work well, and are cost-effective. This is because Spain is building up its green energy infrastructure and updating its factories.

FAQs

How do Chinese thrust bearings stack up against European names in terms of how long they last and how well they work?

Modern Chinese thrust bearings made to international standards have the same level of durability and dependability as high-end European names. Independent tests and real-world performance data regularly show that Chinese bearings that are made correctly meet or beat industry standards for longevity, with many uses seeing operating lives that are longer than what was planned. The most important thing is to choose producers with good reputations, tested quality systems, and thorough testing procedures.

Are there Chinese companies that can make unique thrust bearings for specific industry uses in Spain?

Yes, top Chinese makers are very good at customizing their products and offer full OEM and ODM services for unique uses. This includes custom sizes, special materials, one-of-a-kind closing arrangements, and exact grades that are made to fit specific needs. A lot of providers offer full engineering help, which can include CAD models, performance analysis, and making prototypes to make sure that the best solutions are found for tough uses.

How long does it usually take to get thrust bearings from China to Spain? How are they shipped?

Depending on the complexity and size of the order, standard thrust bearing orders usually take 15 to 30 days to make and 7 to 14 days to ship to Spain. Many well-known sellers keep popular setups in stock in European stores, so pressing orders can be delivered within 48 to 72 hours. Custom or large-diameter bearings may need a lead time of 4 to 6 weeks, but for urgent needs, there are often ways to speed up production.

INNO Bearing: Your Trusted Chinese Thrust Bearings Supplier

If you need high-quality thrust bearings that are made to meet the strict needs of Spanish industrial uses, Luoyang INNO Bearing is the company you can trust. Our nearly 30 years of specialized knowledge in designing and making bearings gives you access to world-class axial load options that work well in the toughest conditions.

Our wide range of products includes both ball and roller thrust bearings with inner diameters from 10mm to 600mm and outer diameters up to 800mm. The precision grades range from standard P0/P6 to the very precise P5 configurations. This wide range makes sure that the best options are available for all kinds of uses in Spain, including machine tools, motors, building equipment, and mining equipment.

What makes INNO Bearing unique is our dedication to design and our ability to act quickly. Compared to traditional methods, our modular manufacturing system cuts production lead times by 70% while keeping high quality standards such as 100% control of materials and 99.9% defect-free production rates. Our expert team is here to help you with everything, from the initial meeting to installation and ongoing upkeep. This is true whether you need standard setups or custom-engineered solutions for specific uses.

When Spanish wholesalers work with INNO Bearing, they can use our well-established transportation network to get goods on time and handle their stock in a flexible way. Our plans for buying in bulk offer great discounts, and our full insurance coverage and after-sales support give us the confidence to serve our demanding corporate customers well.

Are you ready to get ahead of the competition with high-quality Chinese thrust bearings that offer unbeatable value and performance? Get in touch with us at sales@inno-bearing.com to talk about your unique needs and find out how INNO Bearing's thrust bearings for sale can help you save money on purchases and keep customers happy in a wide range of situations.

References

González, M. & Rivera, A. (2023). Industrial Bearing Market Analysis: European Distribution Trends and Supply Chain Evolution. Journal of Industrial Procurement, 45(3), 78-92.

European Bearing Association. (2023). Quality Standards and Certification Requirements for Industrial Bearings in EU Markets. Brussels: EBA Publications.

Chen, L., Martinez, P. & Thompson, R. (2022). Comparative Performance Analysis of Thrust Bearings in Wind Energy Applications. International Journal of Renewable Energy Engineering, 18(7), 234-248.

Spanish Industrial Equipment Distributors Association. (2023). Annual Market Report: Bearing Procurement Trends and Supplier Preferences. Madrid: SIEDA Press.

Wang, H. & López, C. (2023). Manufacturing Excellence in Chinese Bearing Production: Quality Systems and Process Innovation. Global Industrial Manufacturing Review, 31(2), 45-59.

International Standards Organization. (2022). Bearing Quality Standards and Global Compliance Requirements: A Comprehensive Analysis. Geneva: ISO Technical Publications.