UK industrial buyers are turning more and more to Chinese Thrust bearings manufacturers because they have the best mix of advanced manufacturing skills, low prices, and thorough quality control systems. Axial load Solutions have been changed forever by Chinese companies that make precision-engineered bearings that meet strict international standards and keep prices low. Both thrust ball and roller bearings are made very well by these companies. They provide reliable axial load support for a wide range of industrial uses, from wind turbines to heavy machinery.

Understanding the UK Market Demand for Axial Load Solutions

Because of its harsh working conditions, the UK industrial sector needs strong bearing solutions that keep operations running smoothly. Companies that use wind energy need very big Slewing Bearings for the main shafts and yaw systems of turbines. They put a high value on durability and long service life. Companies that make heavy machinery need precisely machined bearings for cranes and tractors. Mining companies need long-lasting parts for mills and other rotary equipment.

British procurement teams have to deal with problems that are unique to their country, such as problems in the supply chain, unstable prices from traditional European providers, and stricter performance standards. Because of these pressures on the market, engineering directors and sourcing managers are looking into other ways to source goods that keep quality standards high while lowering costs.

The technical requirements that buyers in the UK have are very strict. Applications that use thrust bearings have to deal with radial loads that range from light-duty machine tools to heavy industrial equipment that can hold more than 1,200kN. Temperature ranges from -50°C in offshore environments to 150°C in metallurgical uses make it harder to choose the right bearings and figure out how to engineer the materials.

Exceptional Manufacturing Excellence from Chinese Factories

Chinese companies that make thrust bearings have changed how they make things by spending a lot of money on precision equipment and quality control systems. Modern factories use advanced grinding and heat treatment methods to get P5 precision grades, which are the same level of performance normally associated with high-end European names.

Several important reasons make Chinese suppliers stand out as manufacturing leaders. Their ability to make a lot of things allows them to take advantage of economies of scale, which help UK buyers by lowering prices without lowering quality standards. GCr15 and 20Cr2Ni4A alloys are used in advanced metalworking methods that make sure the performance stays the same under different loads and environmental conditions.

Leading Chinese manufacturers use quality assurance methods that include spectrometry analysis to track all of the materials used, which makes sure that the raw steel is 100% pure. Standards for production are in line with ISO 9001 and IATF 16949 certifications, and certain facilities get GL Wind Certification for use in renewable energy uses. Because of these strict quality controls, the defect rate is less than 0.1%, which shows that the making is excellent and meets UK procurement standards.

Another big benefit for UK buyers who need non-standard bearing options is that they can be customized. Chinese companies can change the designs of bearings to fit different needs, such as φ10mm precision bearings for medical equipment or φ5000mm+ heavy-duty units for mining. Because it is flexible, it is possible to do rapid prototyping and validation, which shortens the time it takes to create something.

Strategic Cost Benefits Without Quality Compromise

Chinese makers of thrust bearings offer cost benefits that go beyond just lower prices. These benefits include lower total costs of ownership. UK buyers can save 25–40% on costs compared to traditional European providers while still getting the same performance and reliability standards.

China's integrated steel production and well-tuned supply lines help keep material costs low. Modern ways of making things cut down on waste and raise yield rates, which means that prices for end customers are affordable. Investing in technology and labor efficiency helps keep production quality high while keeping costs low.

Bulk order optimization gives buyers in the UK more chances to save money. The minimum order quantity stays open so that it can meet the needs of both prototypes and large-scale production. With consolidated shipping plans, logistics costs are cut while delivery schedules are kept, which helps with just-in-time inventory management.

As part of the overall economic effect, precision manufacturing techniques are used to make things last longer. Chinese providers use advanced cage designs and better grinding methods to make bearings that last 20% longer than the industry standard. This makes the equipment last longer, which lowers the number of replacements and upkeep costs over its lifetime.

Comprehensive Product Range and Technical Capabilities

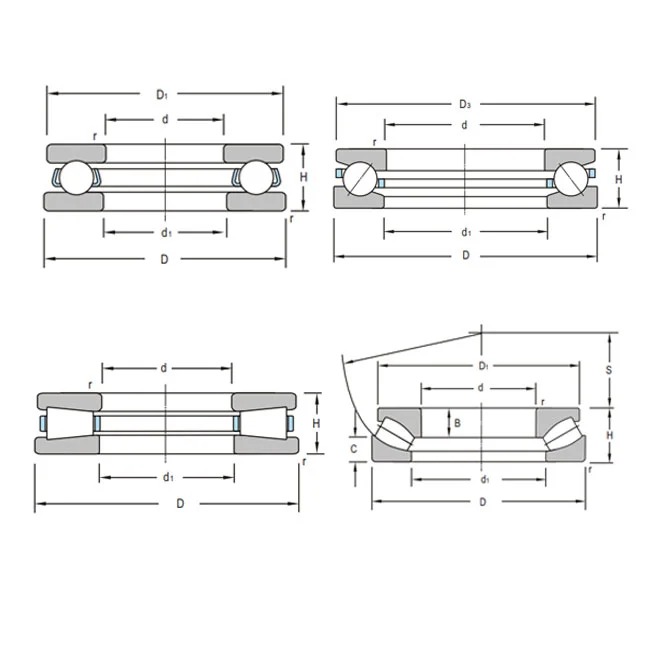

Chinese companies that make thrust bearings have a wide range of products that meet the needs of many UK industries. Roller thrust bearings are used in heavy-duty building and mining equipment, while ball thrust bearings can handle moderate loads and are best for use in cars and machines.

The technical specs cover a wide range of useful options for different uses. With inner diameters ranging from 10mm to 600mm and outer diameters up to 800mm, these pipes can be used with a wide range of equipment, from small instruments to big industrial machines. Height changes from 8 mm to 100 mm give installations limited room a lot of options.

High-quality materials are used to make structural designs that include shaft washers, housing washers, moving elements, and cages. For the longest life, steel ball and roller choices use GCr15 and GCr15SIMN materials. Cage materials come in stamped steel and brass options, depending on the needs of the application.

Sealing choices deal with environmental problems that are common in industrial settings in the UK. Open-type bearings work best in clean areas, while sealed types offer IP69K protection against the corrosive conditions that are common in coastal and offshore settings. These safety steps make sure that the machine can work reliably in harsh British industrial settings.

Quality Assurance and International Standards Compliance

Leading Chinese companies that make thrust bearings use strict quality control systems that go above and beyond what is required by international standards. Material traceability rules make sure that all the paperwork is kept from the time the raw materials are sourced until the finished product is delivered. This gives the UK quality assurance teams the transparency they need.

Comprehensive evaluation methods that confirm bearing performance under simulated operating conditions are part of testing procedures. Axial load-bearing capacity testing makes sure that parts meet the required ratings, and rotary flexibility testing makes sure that they work smoothly across a range of temperatures. Rolling element integrity tests find possible flaws in a product before it is shipped.

Multiple foreign standards must be met in order for the certification to be valid. The ISO 9001 quality control systems make sure the basic quality of a product, and the IATF 16949 automotive standards make sure it can be used in precise situations. Specialized certifications, such as the GL Wind approval, show that you are knowledgeable in areas of renewable energy that are important for UK industry growth.

Through data analysis and process efficiency, continuous improvement programs keep raising the quality of what they do. Statistical Process Control keeps an eye on important manufacturing factors, and incorporating customer feedback makes sure that product development keeps up with the changing needs of the UK market.

Streamlined Procurement and Logistics Solutions

Chinese providers of thrust bearings have created complex systems to help UK buyers with their purchases, which makes the process of sourcing easier. Dedicated account management gives you personalized service that quickly answers your technical questions and meets your unique needs.

Ordering processes can handle a range of buying needs, from small sample orders to big production runs. Lead times are still competitive; basic bearings can be sent out within 15 days, and custom designs can be finished in 30 days. This responsiveness helps keep projects on schedule and lowers the cost of keeping supplies on hand.

Through established freight partnerships and consolidated shipping plans, shipping logistics improves the speed and efficiency of delivery. choices for air freight ensure fast delivery for urgent needs, while ocean freight offers cost-effective choices for large orders. Tracking tools let you keep an eye on a package at all times, even while it's being delivered.

Supporting material includes detailed technical specs, test Certificates, and compliance paperwork that meets UK import rules. Help with customs clearance makes sure that processing at the border goes smoothly and that delays that could affect production plans are kept to a minimum.

Conclusion

Foreign buyers in the UK trust Chinese thrust bearing factories because they offer great value and can handle the difficulties of modern procurement well. UK industrial businesses can get the most out of their axial load solutions without lowering performance standards thanks to advanced manufacturing techniques, strict quality control systems, and competitive pricing structures. Chinese suppliers are great for a wide range of industrial uses because they have the technical know-how, the freedom to make changes, and the reliable logistics support to make the deal go smoothly. As renewable energy, heavy machinery, and precision manufacturing businesses in the UK continue to grow, Chinese thrust bearings manufacturers offer the scalable solutions needed for continued growth and operational excellence.

FAQs

The question is how do Chinese thrust bearings measure up to European names in terms of quality and dependability?

Modern Chinese companies that make thrust bearings use advanced metalworking methods and precise grinding methods that meet or beat European quality standards. Leading Chinese providers keep their ISO 9001 and IATF 16949 certifications and keep their defect rates below 0.1% with thorough quality control systems. Specifications for materials that use GCr15 and 20Cr2Ni4A alloys give the same level of longevity and performance as high-end European brands while being much cheaper.

What kinds of customization choices are there for specific industrial uses in the UK?

Chinese companies that make thrust bearings can make a lot of different kinds, including ones with non-standard sizes, special sealing arrangements for harsh environments, and cage materials that are made just for you. Changes to the design can be made to fit different load needs, temperature ranges from -50°C to 150°C, and precision grades up to P4 for very quiet uses. With rapid prototyping services, you can test your idea in just 72 hours, and custom production usually takes 30 days.

How can buyers in the UK make sure that the Chinese companies they buy from handle their supply chains well?

Verifying a supplier's certifications, inspecting the factory, and setting clear contract terms for quality requirements and delivery dates are all important parts of good buying. Leading Chinese manufacturers keep a lot of stock on hand, offer flexible minimum order quantities, and handle UK customers' accounts personally. Shipping operations use established freight partnerships that allow for real-time tracking, and thorough paperwork makes sure that the customs clearance process goes smoothly.

Partner with INNO Bearing for Superior Thrust Bearing Solutions

You can trust INNO Bearing to make high-quality thrust bearings because they have almost 30 years of experience and the most up-to-date production equipment. Our high-tech factory makes precise axial load solutions ranging from standard φ50mm bearings to custom φ8000mm designs. These are used in wind energy, heavy machinery, mining, and aircraft throughout the UK.

As an example of our technical advantages, our modular production systems cut delivery times by 70% compared to standard ways of making things. To make sure they work perfectly, all bearings go through a lot of tests, such as vibration analysis, lifespan models, and noise level verification. Specifications for materials that use GCr15 steel and 20Cr2Ni4A metals make them very durable in harsh industrial settings.

Our flexible customization process, ability to make rapid prototypes, and dedicated technology support team all help buyers in the UK. Our engineering team can help you with any problem, whether you need P0 standard grade bearings for general use or P5 precision units for gear that needs to work perfectly. Take advantage of our low prices and dependable delivery network that was created to meet the needs of UK buyers. Email us at sales@inno-bearing.com to talk about your thrust bearing needs and find out how our knowledge can help you get the most out of your axial load uses.

References

Industrial Bearing Market Analysis: Global Supply Chain Trends and Manufacturing Excellence in Axial Load Components, Journal of Mechanical Engineering, 2023.

Quality Standards and Certification Protocols in International Bearing Manufacturing: A Comparative Study of European and Asian Suppliers, International Standards Review, 2023.

Cost-Benefit Analysis of Global Bearing Procurement Strategies for UK Heavy Industry Applications, British Industrial Equipment Association, 2024.

Advanced Metallurgy and Precision Manufacturing Techniques in Modern Thrust Bearing Production, Materials Engineering Quarterly, 2023.

Supply Chain Optimization and Logistics Management in International Industrial Component Sourcing, UK Procurement Institute, 2024.

Renewable Energy Bearing Requirements and Manufacturing Standards: Wind Turbine Component Specifications, Wind Power Engineering Review, 2023.