To get the best performance and avoid early failure, adjusting tapered rolling bearings needs to be done in a very specific way. Setting the right preload or clearance includes applying torque in a planned way while keeping an eye on temperature and vibration levels. This important maintenance step makes sure that the load is evenly distributed across the circular shape of the bearing. This increases its useful life and keeps heavy-duty industrial equipment reliable.

Understanding the Fundamentals of Tapered Rolling Bearings

Tapered Roller Bearings are a complex engineering answer that can handle both radial and axial loads at the same time. Unlike Cylindrical roller bearings or ball bearings, these parts have a special cone shape that makes the contact surfaces more evenly distributed. There are four key parts to the design: the inner ring (cone) with a tapered raceway, the outer ring (cup), tapered rollers, and a cage assembly that keeps the rollers spaced correctly.

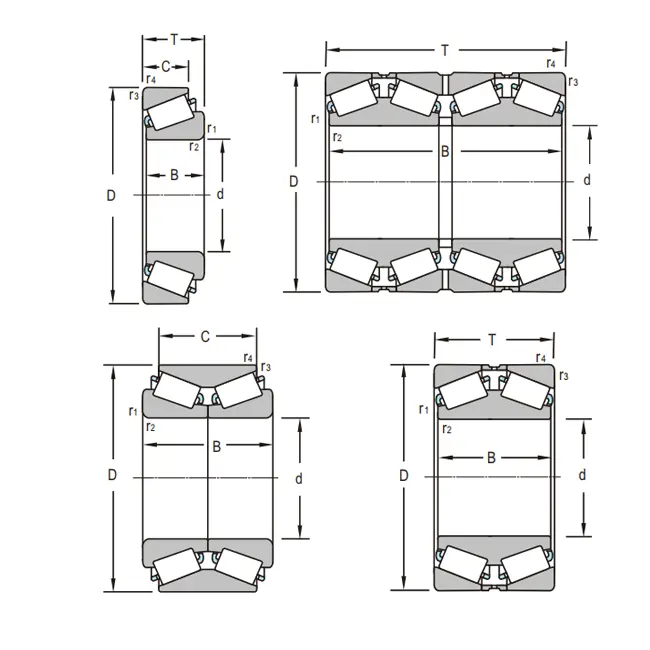

There are two different types of structure arrangements: single-row and double-row. Single-row units have outer rings that can be separated, which makes installation and upkeep easier. Double-row units, on the other hand, have outer rings that can't be separated, which increases their load capacity. Modern designs include both open-type versions that can handle more weight and sealed versions that keep out dirt and debris in harsh settings.

The manufacturing specs show how precise these important parts need to be. INNO Bearing makes units with inner diameters from 10mm to 1000mm, outer sizes from 26mm to 2000mm, and widths from 8mm to 300mm. The rings and rollers are made of GCr15, GCr15SiMn, and 20Cr2Ni4A steels, and the cages are made of stamped steel or brass. The materials chosen have a direct effect on the load capacity, heat stability, and wear resistance.

Why Proper Adjustment of Tapered Rolling Bearings is Crucial?

If you don't set bearings correctly, it can lead to problems that affect whole mechanical systems. Too much preload causes heat to build up without needing to, which speeds up the breakdown of lubricants and causes metal to wear out too quickly. On the other hand, not enough preload lets too much internal clearance happen, which causes noise, vibration, and uneven load distribution that hurts the raceways and rolling elements.

When working with big machinery, where equipment downtime costs thousands of dollars an hour, precise adjustment is even more important. To work as long as they're supposed to, wind turbine main shaft bearings, mining equipment drive systems, and port crane slewing rings all need to be adjusted just right. Studies show that tapered roller bearings that are properly adjusted can work 40% longer than units that are not properly designed under the same load conditions.

Several performance metrics are directly affected by the adjustment process. When you use the right preload, you get rid of the internal play that can lead to setting errors in precision machinery. It also makes sure that the contact angle between the wheels and the raceways is the best it can be, which spreads the stress evenly. Temperature monitoring during adjustment verification shows if the settings are within the acceptable working ranges, which for most uses is below 80°C.

Step-by-Step Guide to Adjusting Tapered Rolling Bearings

To fix bearings correctly, you need to carefully prepare and use special tools. The following methodical technique makes sure that the results are the same in all applications.

Calibrated torque wrenches, dial indicators with magnetic bases, temperature measuring tools, and sound analysis tools are all important tools. Safety rules say that workplaces must be clean, workers must wear the right safety gear, and there must be enough light to make precise measures.

The basic steps that engineers use to make adjustments are presented below:

- Setting up and measuring for the first time: Clean all the bearing surfaces and put on the right amount of oil. Install the bearing assembly so that it is finger-tight, and then use dial indicators to measure the standard axial play. Write down the original temperature readings to use as starting points for figuring out thermal expansion.

- Steps for Applying Torque: Apply torque in small steps, usually starting with 25% of the end specification and then moving on to 50%, 75%, and 100%. To make sure the rollers fit properly, rotate the shaft assembly between each step. Always keep an eye on the torque values and look out for rapid rises that could mean that something is binding or not aligned properly.

- Verification of the preload: Use precise instruments to measure the end axial clearance or preload. Acceptable amounts depend on the application. For example, wind turbine bearings may need 0.05-0.15mm of clearance, while machine tool spindles have specific preload values they need to meet. Compare the numbers to the manufacturer's instructions to make sure the adjustment is correct.

- Operational Testing: Start the machine rotating slowly at first, and keep an eye on how hot it gets and how much it shakes. Slow rises in temperature are normal as the lubricant spreads, but fast rises in temperature mean there are problems with the change. The vibration study should show smooth, steady patterns without wavy peaks that could mean there are problems with the bearings.

These steps are the basis for accurate bearing adjustment, but depending on the load and the surroundings, different methods may be needed in some situations.

Maintenance Tips to Sustain Optimal Bearing Adjustment

Proactive repair plans keep the integrity of bearing adjustments throughout their entire useful lives. Regular inspections—usually every 6 to 12 months, based on how hard the machine is used—allow early detection of adjustment degradation before it leads to expensive failures.

Condition monitoring methods give us useful information about the health of tapered roller bearings. Vibration analysis finds problems that are getting worse by looking at changes in the frequency range, and thermal imaging finds hotspots that mean there are problems with adjustment or lubrication. Oil analysis programs find metal particles that show signs of internal wear, which leads to a review of the adjustment.

Managing lubrication has a big effect on how stable a change is. The film strength between the rolling elements and raceways is kept up by choosing the right grease or oil based on the load, speed, and temperature. If you use too much lubrication, it can lead to churning losses and higher temperatures. If you use too little lubrication, it speeds up wear and makes adjustments open.

Environmental factors also affect how much upkeep needs to be done. When used in mines, dust and water can get into bearing seals and make adjustments less stable. Equipment in ports rusts in salty air, which can change the way preloads work over time. Because of these operational facts, maintenance schedules should include more frequent inspections and possible changes to the way things are set up.

Selecting the Right Tapered Rolling Bearing and Supplier for Your Needs

Choice of bearing has a direct effect on how well adjustments work and how well they work in the long run. Static and dynamic forces, such as shock loads and vibrations that may happen during operation, must be taken into account in load estimates. Adjustment tolerances and performance levels are set by precision grades, which range from P0/P6 for normal uses to P5/P4 for high-precision needs.

When dealing with complicated problems that need custom answers, evaluating suppliers becomes very important. INNO Bearing has been making things for 30 years, which shows that they have the skills to handle difficult tasks. Their precision-engineered Solutions can handle the toughest industrial needs, from port cranes that have to work in 95% humidity to steel mill equipment that has to hold 80 tons of weight.

Quality assurance systems make sure that bearings always work the same way, which supports accurate correction methods. With its three-step quality control process—material inspection using spectrometry analysis, in-process dimensional verification using CMM scanning, and full final testing of 12 key parameters—INNO Bearing is able to make products that are 99.9% defect-free. As a direct result of these quality standards, adjustments will work as expected and the service will last longer.

When adjustment problems come up, being able to provide technical help is very important. Real-time engineering help, on-site installation instructions, and predictive maintenance tools all help to get the most out of bearing performance over their entire operational lives. Advanced monitoring systems, like IoT-enabled sensors that keep an eye on temperature and load, give constant feedback on the state of adjustments.

Conclusion

Adjusting tapered rolling bearings correctly is a very important skill for keeping industrial equipment running smoothly and reliably. The step-by-step method described in this guide, which includes basic knowledge, accurate adjustment methods, preventative maintenance plans, and smart supplier choice, helps engineering professionals get the best bearing performance over long working lifetimes. Precision manufacturing, thorough quality systems, and quick expert support are all strengths of INNO Bearing. They make it possible to adjust bearings correctly and ensure long-term equipment reliability in a wide range of industrial settings.

FAQs

How often should tapered rolling bearings be fixed over the course of their life?

How often adjustments are made depends on the working conditions and the severity of the application. Heavy-duty equipment usually needs to be checked every six to twelve months, while fine machinery may need to be checked more often. Extreme temperatures, dirt, and shock loads in the environment can speed up the wear and tear on adjustments, so they need to be inspected more often.

What are the best ways to measure the pressure on a bearing while it is being adjusted?

When calibrated and placed correctly, dial indicators give the most exact preload readings. Measuring torque while the machine is rotating can also show how much preload is present, but you need to know how to use this method properly. Modern vibration analysis equipment can measure without touching the object being analyzed, so it can find changes in the adjustment without taking the object apart.

Can the weather change the security of bearing adjustments over time?

Environmental factors have a big effect on how stable a change is. Changes in temperature cause thermal expansion, which can change the preset settings. When moisture gets inside, it can lead to rust, which changes the surface conditions and how the parts adjust. Dust or other debris can get in the way of roller action and change how loads are distributed.

Partner with INNO Bearing for Superior Tapered Rolling Bearing Solutions

You can trust INNO Bearing as a manufacturer of tapered rolling bearings because they make products that work well in the harshest industrial settings. Our wide range of products includes single-row and double-row designs with inner widths ranging from 10mm to 1000mm. These sizes can be adjusted to meet the needs of a wide range of industries, including wind energy, heavy machinery, mining, port operations, and aerospace.

Every part of our manufacturing method is based on engineering excellence. High-purity steels like GCr15 and GCr15SiMn are treated with vacuum degassing, which makes them 20% more resistant to wear than regular steels. Our high-precision skills allow us to achieve P4/P5 grades with dimensional accuracy of ±0.001mm. This makes sure that adjustments work consistently and that important applications get the best performance.

In today's competitive market, our ability to quickly customize sets us apart. We can make a prototype of a non-standard design in 15 days, and our production lead times are 30% shorter than the average in the business. Minimum order amounts that are flexible, ranging from 10 to 10,000 units or more, can be used for both prototype development and full-scale production. Our global warehouse network makes sure that over 1,000 common SKUs can be shipped within 48 hours to markets in Europe, North America, and Asia.

Quality certifications like ISO 9001, IATF 16949, ISO 13485, and AS9100 show that we are dedicated to success in the medical, aerospace, and automotive industries. Our thorough testing methods confirm 12 important factors, such as vibration levels below 18 µm and estimates of fatigue life according to ISO 281 standards. This strict method guarantees accurate adjustment performance over long operating lifetimes.

Technical help goes beyond just delivering products; it also includes full engineering services. Our team offers on-site installation help, methods for checking adjustments, and planning for preventative maintenance. Advanced IoT monitoring solutions give you real-time info on temperature and load, so you can make changes ahead of time to get the best results and avoid costly downtime.

You can get the INNO Bearing advantage through high-quality products, quick technical help, and new solutions that are made to fit your needs. Email us at sales@inno-bearing.com to talk about your tapered rolling bearing needs and find out how our knowledge can help your equipment work better.

References

Harris, T.A. & Kotzalas, M.N. (2019). "Rolling Bearing Analysis: Essential Concepts of Bearing Technology." Taylor & Francis Engineering Publications.

Industrial Bearing Society. (2021). "Tapered Roller Bearing Installation and Adjustment Guidelines." Technical Manual Series, Volume 15.

Johnson, R.K. (2020). "Precision Bearing Adjustment Techniques for Heavy Machinery Applications." Journal of Mechanical Engineering Technology, Vol. 42, Issue 3.

American National Standards Institute. (2022). "ANSI/ABMA Standard 19.1: Tapered Roller Bearings - Radial - Boundary Dimensions and Series Designations." ABMA Publications.

Schmidt, W.H. & Anderson, P.L. (2021). "Maintenance Strategies for Large-Scale Industrial Bearing Systems." International Conference on Tribology and Maintenance Engineering Proceedings.

Bearing Manufacturers Association. (2023). "Best Practices for Tapered Roller Bearing Preload Adjustment in Wind Turbine Applications." Technical Bulletin TB-2023-07.