Chinese makers offer great prices, cutting-edge manufacturing, and dependable delivery for tapered bore bearing Solutions, so Brazil's mining industry is relying on them more and more. Self-aligning roller bearings with tapered inner holes have great adjustability because of nut-controlled radial space. This makes them perfect for mining equipment that needs exact shaft system adjustments. From processing iron ore to mining copper, Brazil's tough mineral extraction operations need the broad custom choices, quick delivery times, and technical knowledge that Chinese companies offer.

Understanding Tapered Bore Bearings and Their Role in Mining Equipment

Mining needs strong bearing solutions that can handle heavy loads and keep precision in tough situations. Self-aligning roller bearings with tapered holes on the inside are a special type made for situations that need changeable radial clearance and better load distribution.

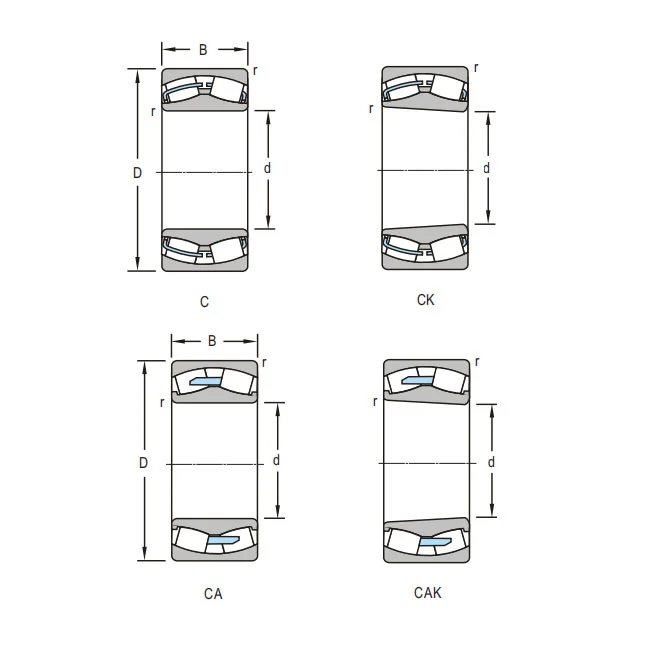

The special building has an inner ring with tapered holes (1:12 or 1:30 ratios) and double-ribbed outer rings with double-row spherical rollers in safe cages. In this open setup, thermal growth is possible and the structure stays intact even when it is used all the time. The GCr15 bearing steel construction is very durable because the inner rings, outer rings, and rollers are made from high-quality materials that don't wear down easily in tough mining situations.

Because these bearings can align themselves, they work well in mining uses. This feature helps deal with shaft deflection and misalignment that happen often when using heavy equipment. With the changeable radial clearance feature, maintenance teams can keep the bearing working well during its entire service life. This greatly reduces downtime and extends the amount of time the equipment can be used overall.

Critical Performance Factors Driving the Brazil Mining Industry's Bearing Selection

When Brazilian mining companies choose tapered bore bearing options for their work, they put performance features first. The most important thing is load capacity. Equipment that moves tons of stuff needs bearings that can support radial and axial forces at the same time.

The level of precision needed changes depending on the application. Most mining equipment standards are met by P0 and P6 precision levels. The inner diameter can be anywhere from 30 to 500 mm, and the outer diameter can be anywhere from 62 to 1,000 mm. This makes the product useful for a wide range of equipment, from conveyor belts to very large grinding mills. Width requirements of 20–200 mm make sure that the load is spread evenly across the surfaces of the bearing.

The material makeup is very important to how long the bearing lasts. GCr15 bearing steel has the best hardness and resistance to wear, and cages made of stamped steel or brass can be used to make the bearing work in different circumstances. Chinese makers have come up with specialized ways of applying heat that improve the properties of materials beyond the normal standards. This means that the materials can be used for longer periods of time without having to be fixed or replaced.

Temperature resistance makes it possible for mining equipment in Brazil to work all the time in tropical conditions, where machines often run at higher temperatures because of the weather and heat they generate themselves. The self-aligning function keeps the best performance at any temperature by making up for the effects of thermal expansion.

Why China is the Sourcing Hub for Tapered Bore Bearings in Brazil's Mining Sector?

China has become the most popular place to get goods because of advances in technology, the size of its factories, and its ability to keep costs low. The country's bearing industry has bought a lot of precise manufacturing tools and quality control systems that are as good as those from Europe and America, which are the industry's main traditional suppliers.

China's manufacturing skills include the whole production cycle, from working with raw materials to putting things together and testing them. Advanced CNC machining centers make sure that the dimensions are always correct, and complex heat treatment facilities make sure that the qualities of the materials are the best they can be for demanding uses. Quality assurance programs like raw material analysis and thorough performance testing make sure that the products are reliable.

Chinese makers offer supply chain benefits like flexible production scheduling and large inventory management systems. Regional distribution networks make sure quick delivery to Brazilian ports, and specialized packaging keeps the tapered bore bearings safe while they are shipped by water. For common mining uses, many suppliers keep special stock on hand so that they can quickly replace broken parts in an emergency.

Lowering costs doesn't have to mean lowering quality. Instead, costs can be kept low by using efficient manufacturing and getting materials from competitive suppliers. Chinese makers have reached economies of scale that let them keep up with international quality standards and mining industry rules while still offering good prices.

Practical Guide for Brazilian Procurement Managers: Choosing Chinese Tapered Bore Bearings

To procure successfully, you need to evaluate supplier capabilities against specific application standards in a systematic way. Procurement managers need to make clear requirements that include expected service life, environmental conditions, precision classes, and load ratings.

Quality management systems, manufacturing certifications, and technical help should all be part of the supplier evaluation criteria. ISO certifications show a promise to always meet the same quality standards, and certifications that are specific to the business prove knowledge of mining applications. It is very important to be able to get technical help when you are doing complex installations or trying to fix something.

Communication methods make sure that projects run smoothly from the very beginning to the end of the delivery and installation. Clear documentation needs, such as installation instructions, material Certificates, and dimensional inspection reports, keep people from getting confused and make it easier to check the quality when it arrives.

Building long-term partnerships helps both sides by giving them a better understanding of each other's needs and making the buying process easier. When you have established relationships, you get to see new technical gadgets and get treated like a VIP during busy times.

Conclusion

Brazil's mining industry favors Chinese tapered bore bearing solutions because specialized providers offer advanced manufacturing, good prices, and dependable delivery. Self-aligning roller bearings with tapered inner holes can be adjusted to change their radial clearance and handle heavier loads. These technical benefits make them an important part of modern mining equipment. Chinese makers have shown they can meet tough standards of quality while offering goods at a lower price compared to traditional suppliers. Procurement managers get help from established logistics networks that make sure supplies are always on hand, as well as full technology support and the ability to make changes to how they want. The best Chinese bearing makers work together with their partners to make things better and come up with new ideas that are based on the needs of the mining industry. This partnership method makes things better in the long term.

FAQs

Why are tapered bore bearings better than regular bearings for use in mining?

The tapered inner hole design lets you change the radial space exactly by moving the nut. This gives you the best load distribution and makes up for shaft deflection, which is common in heavy mining equipment. This adjustability makes the bearing last longer and keeps it working under different load situations that standard bearings can't handle well.

How can businesses in Brazil make sure that Chinese tapered bore bearings are of good quality?

Quality verification means checking the manufacturer's credentials (ISO 9001, standards for the mining industry), asking for reports on the dimensions and materials, and doing the steps for inbound inspection. Honest Chinese suppliers provide a lot of paperwork and allow outside quality checks to show that they meet foreign standards.

What maintenance steps get the best performance out of tapered bore bearings in mining settings?

Regular checks on lubrication, radial clearance, and contamination protection are important ways to keep things working. The feature that allows you to change the clearance makes it possible to fine-tune it during the entire service life. At the same time, the right sealing and filtering systems stop abrasive particles from getting in and making wear happen faster in mining settings.

INNO Bearing: Your Trusted Partner for Premium Tapered Bore Bearing Solutions

Luoyang INNO Bearing Co., Ltd. is a top maker that specializes in large and non-standard bearing solutions and has almost 30 years of experience in the field. Mining companies around the world, including big ones in Brazil looking for reliable, cheap options, have praised our knowledge of designing and making tapered bore bearings.

Self-aligning roller bearings with tapered inner holes in a wide range of sizes, including unique shapes up to φ5000 mm, are available in our full product line. Precision machining, specialized heat treatment, and strict quality control are all part of the advanced manufacturing skills that make sure the equipment works well in difficult mining conditions. Each bearing is tested in a number of ways to make sure that the dimensions, force capacity, and material properties are all correct.

Key benefits are quick prototype creation for custom applications, faster shipping times for standard products, and full technical help during the entire bearing lifecycle. To get the most out of your bearings, our engineering team helps with installation, care, and troubleshooting. The company keeps a lot of common mining equipment in stock so that they can make emergency shipments when downtime threatens the production plan.

When Brazilian mining businesses work with INNO Bearing, they get good prices, plenty of options for how to make their products, and great management of their supply chains. To talk about your needs and find out how our tapered bore bearing manufacturing can improve your mining processes, email us at sales@inno-bearing.com.