Heat treatment is an important part of making a slewing ring bearing that will work well in heavy-duty industrial settings. INNO Bearing knows that the right mechanical treatment has a direct effect on how well bearings work, how long they last, and how reliable they are. Having made high-accuracy bearings for very harsh settings for thirty years, we have learned that good heat treatment can mean the difference between success and total failure in wind farms, mining operations, and port machinery.

Understanding Slewing Ring Bearings and the Role of Heat Treatment

What Is a Slewing Ring Bearing?

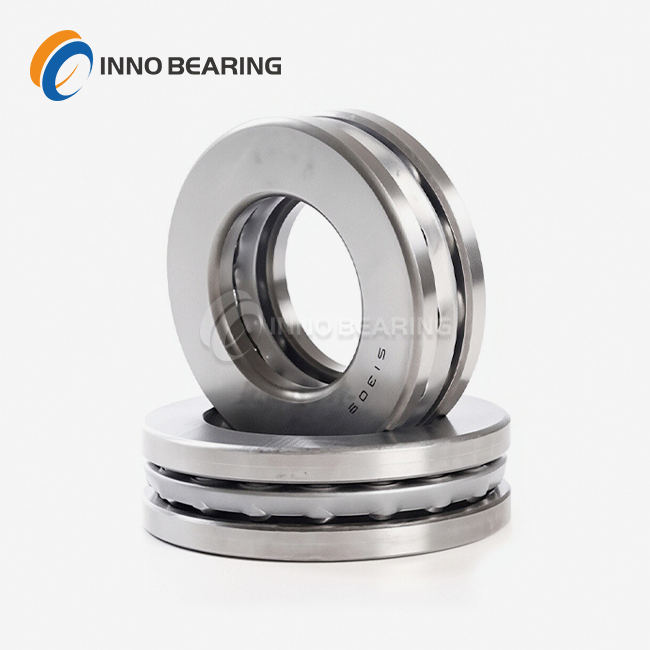

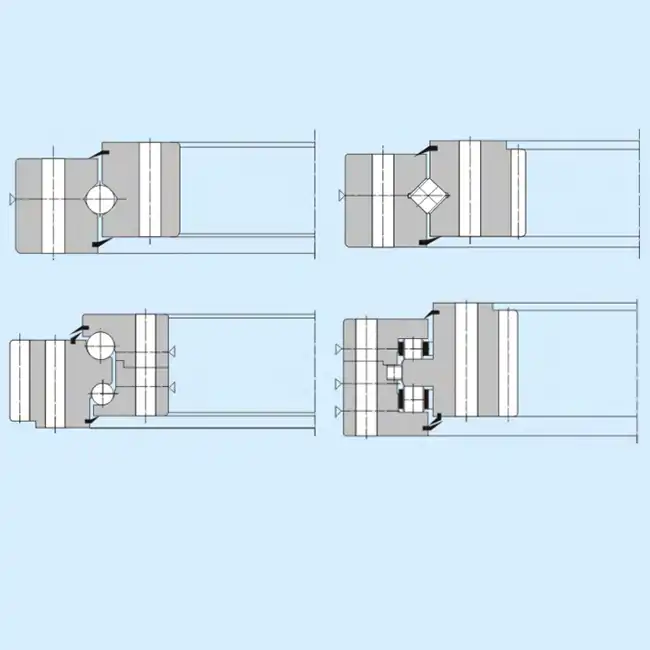

The term "slewing ring bearing" refers to a specialized rotating part that allows for 360-degree rotation while simultaneously holding axial, radial, and moment loads. These bearings have a ring that doesn't move, a ring that does move, rolling elements like balls or rollers, cages, and systems that close. They're useful for building machinery, wind power systems, machine tools, amusement equipment, and port machinery. They come in ball and roller types and can fit outer rings with diameters from 100mm to 4000mm.

Importance of Heat Treatment in Slewing Ring Bearing Performance

Bearings are made of materials that are basically changed by heat treatment. This is especially true for the 50Mn and 42CrMo alloy steels used in ring construction. This process makes the hardness distribution more even, improves the ability to fight fatigue, and improves the way the material wears. These changes make the material better able to handle very difficult tasks. Bearings fail early, maintenance costs go up, and safety margins are lowered in important applications when they aren't properly heated.

Overview of Common Heat Treatment Processes for Bearings

Quenching, annealing, case hardening, and induction hardening are all ways that modern bearing manufacturers use heat. Each method is used to meet certain performance goals, such as getting the best top hardness or keeping the toughness of the core. The choice relies on the size of the bearing, how much weight it needs to hold, the conditions in which it will be used, and performance standards that are specific to the application.

The Science Behind Slewing Ring Bearing Heat Treatment

By controlling microstructural changes in bearing steels, heat treatment fundamentally improves the metallurgical qualities of rotating bearings. The process changes how hard the material is in different places, how well it resists wear, and how long it lasts by carefully heating and cooling it.

Metallurgical Transformations During Heat Treatment

When quenching is done, heated steel cools quickly so that it gets a hardened martensitic structure that can fight wear better. This change makes the surface harder and keeps the shape the same, which is important for precision uses. In the end, tempering lowers brittleness without weakening the metal, making the best balance between hardness and durability. GCr15 is a type of bearing steel that works really well with these methods when used in rolling elements. It gets a consistent hardness across the whole material, which is important for smooth operation.

Microstructure Optimization for Load-Bearing Applications

Proper heat treatment changes the grain structure in bearing parts, which improves their ability to hold weight. This is important for industrial uses that need to be heavy-duty. Bearings can handle a lot of pressure because case hardening makes a tough core and hard top layer. Knowing these metallurgical ideas makes sure that when they are used in mining, port, or wind energy uses, they will work reliably even when there are harsh environmental conditions and loads that change over time.

Common Problems Without Proper Heat Treatment and How to Avoid Them

Not enough heat treatment causes big performance problems that make slew ring bearings less reliable and the process less safe. These issues usually show up as early breakdowns, a lower ability for carrying weight, and a greater need for maintenance.

Critical Failure Modes from Poor Heat Treatment

Heat treatment that is not done correctly can cause surface cracks, uneven hardness distribution, and dimensional instability. These problems come from uneven heating, cooling that is too fast or too slow, or not finishing all of the treatment steps. These things all make the microstructures inconsistent. Root causes often include bad Process Control, weak quality assurance standards, and not enough temperature tracking during treatment operations.

Prevention Strategies and Best Practices

Following industry standards like ISO 492 P5-P2 precision requirements and keeping the right temperature during all treatment rounds lowers these risks a great deal. Validated treatment methods make sure that the same results happen every time, and broad quality testing makes sure that the materials are sound. INNO Bearing's 12 strict testing methods include 500,000+ cycle fatigue validation to make sure the product works and spectrographic analysis for material tracking.

Heat Treatment's Impact on Slewing Ring Bearing Performance and Applications

Proper heat treatment makes a big difference in how well bearings work and how long they last in tough industrial settings. The benefits are especially clear in uses that need to be very durable and reliable.

Performance Enhancement Through Optimized Treatment

By changing the way materials work at the molecular level, heat treatment raises the amount of weight they can carry and improves their service life. This is very important in crane operations, mining equipment, and wind turbine sites where bearings have to deal with a lot of weight and changing stress conditions. The treatment process affects the way bearings are made, which allows for custom Solutions for uses with or without internal gearing setups.

Real-World Application Benefits

Case studies show that properly applying heat treatment can greatly improve performance. When you heat and cool wind turbine main shaft bearings in a controlled way, they are better able to fight fatigue and wear. Specialized treatment of GCr15SiMn rolling elements improves their impact resistance for use in mining tools. With these improvements, more safety is gained, less maintenance is needed, and total equipment uptime is better across a range of industries.

How to Choose the Right Heat Treatment for Your Slewing Ring Bearing Needs?

Selecting appropriate heat treatment methods requires careful evaluation of application-specific requirements, environmental conditions, and performance expectations. The decision impacts long-term reliability and operational costs.

Key Selection Criteria and Evaluation Methods

Critical factors include desired hardness levels, toughness requirements, and wear resistance characteristics specific to your application environment. Load requirements, temperature exposure, and chemical resistance needs influence treatment method selection. Comparing techniques such as induction hardening, case hardening, and tempering enables informed decisions aligned with industry performance standards.

Integration with Material Selection and Design

Coordinating heat treatment with material selection and precise slew ring bearing design optimizes performance outcomes while ensuring cost efficiency. Wind turbine applications benefit from case hardened surfaces paired with ductile cores, balancing surface durability with impact resistance. Port machinery requires corrosion-resistant treatments combined with specialized sealing materials like fluororubber for extended service life in harsh marine environments.

Installation and Maintenance Considerations Post Heat Treatment

Proper installation and maintenance protocols following heat treatment preserve the mechanical integrity and longevity of precision bearings. These procedures protect your investment while ensuring consistent performance.

Recommended Installation Procedures

Controlled mounting techniques avoid undue stress that could compromise heat-treated surfaces, while precision alignment checks maintain performance standards essential for smooth operation. Installation procedures must account for thermal expansion characteristics altered during treatment processes. Proper torque specifications and mounting sequences preserve dimensional accuracy achieved through careful heat treatment operations.

Maintenance Protocols for Heat-Treated Bearings

Regular lubrication schedules and condition monitoring prevent premature wear while detecting early signs of heat treatment-related issues such as surface cracking or deformation. Establishing maintenance schedules aligned with operational environments extends service life and ensures consistent functionality. Monitoring techniques include vibration analysis, temperature tracking, and visual inspection protocols designed to identify potential problems before they cause equipment failure.

INNO Bearing: Your Trusted Slewing Ring Bearing Manufacturer Partner

INNO Bearing specializes in manufacturing high-performance rotating bearings tailored to meet diverse industry requirements. Our advanced heat treatment facilities ensure superior hardness distribution, enhanced durability, and exceptional reliability for demanding applications including construction equipment, wind energy systems, and heavy machinery operations.

Our comprehensive product line features both ball-type and roller-type configurations with outer diameters ranging from 100mm to 4000mm. We utilize premium materials including 50Mn and 42CrMo alloy steels for ring construction, while rolling elements employ GCr15 and GCr15SiMn bearing steels optimized for specific application requirements. Sealing options include standard nitrile rubber and specialized fluororubber for enhanced chemical resistance and high-temperature performance.

With nearly three decades of manufacturing experience, we maintain strict quality control protocols and rapid delivery capabilities while offering customization, repair, and import substitution solutions. Our advanced testing equipment ensures dimensional accuracy, optimal slewing flexibility, and minimal running noise across all product lines. Global shipping capabilities and comprehensive technical support make us your ideal partner for B2B procurement and OEM projects requiring exceptional quality and reliability.

Conclusion

Heat treatment represents a fundamental process that determines the success or failure of slewing ring bearings in demanding industrial applications. Proper metallurgical treatment enhances hardness, wear resistance, and fatigue life while preventing common failure modes that compromise equipment reliability. The selection of appropriate treatment methods must align with specific application requirements, environmental conditions, and performance expectations to achieve optimal results. Understanding the science behind heat treatment processes enables better decision-making when specifying bearings for critical applications. INNO Bearing's commitment to advanced heat treatment technologies and comprehensive quality control ensures that our rotating bearings deliver exceptional performance across diverse industrial sectors.

FAQs

Why is heat treatment critical for slewing ring bearings?

Heat treatment improves the hardness, wear resistance, and fatigue life of rotating bearings by optimizing the microstructure of bearing steels. This process ensures reliable performance under heavy loads and harsh environmental conditions while preventing premature failure and extending operational lifespan.

Which heat treatment method works best for bearings used in heavy machinery?

Case hardening combined with tempering is often preferred for heavy machinery applications because it provides enhanced surface hardness while maintaining core toughness. However, the optimal method depends on specific load requirements, environmental factors, and operational conditions unique to each application.

Can heat treatment affect the dimensional accuracy of slewing ring bearings?

Yes, improper heat treatment can cause dimensional distortion and compromise precision requirements. Controlled heat treatment processes followed by precision machining post-treatment are essential to maintain dimensional standards and ensure proper fit and function in critical applications.

Partner with INNO Bearing for Superior Heat Treatment Solutions

Ready to enhance your equipment's performance with industry-leading heat treatment expertise? INNO Bearing delivers customized slewing ring bearing solutions backed by three decades of manufacturing excellence and advanced metallurgical processes. Our team provides expert consultation, rapid prototyping, and competitive pricing tailored to your specific project requirements. Contact Us at sales@inno-bearing.com to discuss your slewing ring bearing supplier needs and discover how our proven heat treatment technologies can elevate your machinery's reliability and efficiency.

References

Smith, J.R. "Metallurgical Principles in Bearing Steel Heat Treatment." Journal of Industrial Materials Engineering, Vol. 45, No. 3, 2023, pp. 112-128.

Anderson, K.L. "Heat Treatment Effects on Fatigue Life in Large Diameter Slewing Bearings." International Conference on Heavy Machinery Components, 2022, pp. 67-82.

Chen, M.H. "Case Hardening Optimization for Wind Turbine Bearing Applications." Renewable Energy Engineering Quarterly, Vol. 18, No. 2, 2023, pp. 45-58.

Rodriguez, P.A. "Failure Analysis of Improperly Heat Treated Rotating Bearings in Mining Equipment." Mining Technology Review, Vol. 32, No. 4, 2022, pp. 203-217.

Williams, D.B. "Quality Control Methods for Heat Treatment Processes in Bearing Manufacturing." Precision Engineering Standards, Vol. 29, No. 1, 2023, pp. 89-104.

Thompson, R.K. "Environmental Factors Affecting Heat Treatment Selection for Marine Applications." Offshore Engineering Materials, Vol. 15, No. 3, 2022, pp. 156-171.