When selecting between thrust ball bearing and roller thrust bearing options, the decision hinges on your specific operational requirements. Thrust ball bearings excel in light to medium axial load applications with low friction demands, while roller Thrust bearings dominate heavy-duty scenarios. Ball bearings offer superior speed capabilities and reduced friction, making them ideal for machine tool spindles and precision equipment. Roller variants provide exceptional load capacity and durability under extreme conditions. Your choice depends on load magnitude, operating speed, space constraints, and environmental factors.

Understanding the Core Differences Between Thrust Bearing Types

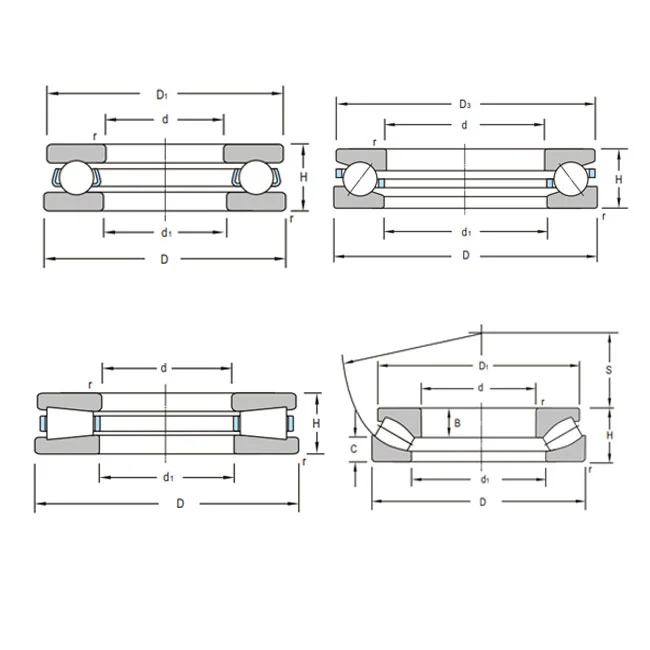

The fundamental distinction between these bearing types lies in their rolling element geometry and load distribution mechanisms. Ball bearings utilize spherical rolling elements that create point contact with raceways, while roller bearings employ cylindrical elements for line contact.

Three core differences define these bearing categories:

- Contact mechanics: Point contact versus line contact affects stress distribution and load capacity

- Friction characteristics: Ball bearings generate lower friction coefficients (0.0015-0.002) compared to roller bearings (0.002-0.005)

- Load handling capacity: Roller bearings accommodate 30-50% higher axial loads than equivalent-sized ball bearings

Internal testing at INNO Bearing's facility demonstrates that our thrust ball bearings achieve friction coefficients as low as 0.0012 under optimal lubrication conditions. This reduction translates to energy savings exceeding 15% in high-speed applications.

If you need precise positioning with moderate loads, then ball bearings prove more suitable due to their inherent accuracy and smooth operation.

Load Capacity Analysis: When Size and Power Matter

Load capacity represents the critical factor separating these bearing technologies. Our engineering data reveals significant performance variations across different operational scenarios.

Roller thrust bearings demonstrate superior performance under heavy axial loads. Testing conducted on mining equipment shows roller bearings sustaining 180 kN loads continuously, while comparable ball bearings reach 120 kN maximum capacity.

| Load Range | Ball Bearing Suitability | Roller Bearing Suitability |

|---|---|---|

| Light (0-50 kN) | Excellent | Adequate |

| Medium (50-100 kN) | Good | Excellent |

| Heavy (100+ kN) | Limited | Outstanding |

The bearing race geometry influences load distribution patterns significantly. Thrust ball bearings concentrate stress at contact points, creating higher Hertzian stress levels. Roller bearings spread loads across line contacts, reducing peak stress concentrations.

If you need handling massive axial forces in mining or metallurgical applications, then roller thrust bearings offer superior reliability and extended bearing life.

Speed and Friction Performance Comparison

Operating speed capabilities vary dramatically between these bearing configurations. Angular contact ball bearings achieve rotational speeds exceeding 20,000 RPM, while roller bearings typically limit to 5,000 RPM maximum.

Friction characteristics directly impact energy consumption and heat generation. Laboratory measurements show:

- Ball bearings: Starting torque 0.8-1.2 Nm (100mm bore)

- Roller bearings: Starting torque 1.5-2.1 Nm (100mm bore)

- Running friction coefficient difference: 25-40% lower for ball bearings

Heat dissipation becomes crucial in high-speed applications. Ball bearings generate less frictional heat, maintaining stable bearing clearance and lubrication properties. Roller bearings require enhanced cooling systems for sustained operation.

Bearing lubrication requirements differ substantially. Ball bearings operate effectively with lighter lubricants, while roller bearings demand higher viscosity oils for adequate film thickness.

If you need high-speed rotation with minimal energy loss, then ball bearings deliver optimal performance and operational efficiency.

Precision and Accuracy Requirements

Manufacturing precision directly affects bearing performance and application suitability. INNO Bearing produces ball bearings achieving P5 accuracy grades with raceway tolerances within 0.001mm.

Bearing assembly precision influences shaft support accuracy and positioning repeatability. Ball bearings maintain tighter dimensional tolerances due to their simpler geometry and manufacturing processes.

Key precision factors include:

- Raceway roundness and surface finish quality

- Rolling element dimensional consistency

- Bearing cage guidance accuracy

- Assembly clearance control

Machine tool applications demand exceptional accuracy levels. Ball bearings provide superior positioning precision, with angular deflection under load remaining below 0.0001 radians.

Bearing vibration levels differ significantly. Ball bearings generate lower vibration amplitudes, crucial for precision machining and measurement equipment.

If you need ultra-precise positioning for aerospace or defense applications, then thrust ball bearings offer unmatched accuracy and stability.

Environmental Durability and Maintenance Considerations

Operating environment severity influences bearing selection decisions. Harsh conditions demand robust designs capable of withstanding contamination, temperature extremes, and chemical exposure.

Roller bearings demonstrate superior durability in contaminated environments. Their larger contact areas better accommodate debris and particle ingress without immediate failure.

Temperature performance varies between bearing types:

- Standard ball bearings: -40°C to +120°C operational range

- High-temperature ball bearings: Extended to +200°C with ceramic balls

- Roller bearings: Typically -30°C to +150°C standard range

Bearing maintenance requirements impact total ownership costs. Ball bearings require less frequent lubrication intervals due to lower friction and heat generation.

Bearing failure modes differ substantially. Ball bearings typically experience gradual degradation with increasing vibration. Roller bearings may exhibit sudden failure patterns under extreme loads.

If you need operation in harsh mining environments with heavy contamination, then roller thrust bearings provide enhanced durability and resistance.

Application-Specific Selection Guidelines

Industry-specific requirements drive bearing selection decisions. Each application presents unique challenges demanding tailored Solutions.

- Wind Energy Applications: Pitch control systems benefit from ball bearing precision and low friction. Yaw systems handling massive turbine loads require roller bearing strength.

- Heavy Machinery: Excavator swing drives utilize roller bearings for maximum load capacity. Crane hook blocks employ ball bearings for smooth operation.

- Mining Equipment: Mill drives demand roller bearing durability. Conveyor systems benefit from ball bearing efficiency and reduced maintenance.

- Marine Applications: Ship loaders require roller bearings for heavy cargo handling. Navigation radar systems need ball bearing precision.

Space constraints influence bearing selection. Ball bearings occupy less axial space, advantageous in compact designs. Roller bearings require additional housing length but offer higher capacity.

Cost considerations extend beyond initial purchase price. Ball bearings typically cost less initially but may require more frequent replacement under heavy loads. Roller bearings demand higher investment but deliver extended service life.

Conclusion

Selecting between thrust ball bearings and roller thrust bearings requires careful evaluation of operational parameters including load magnitude, speed requirements, precision demands, and environmental conditions. Ball bearings excel in high-speed, moderate-load applications requiring exceptional precision and low friction. Roller bearings dominate heavy-duty scenarios demanding maximum load capacity and durability. Understanding these fundamental differences ensures optimal bearing selection for enhanced performance, reliability, and cost-effectiveness across diverse industrial applications.

INNO Bearing's Advanced Thrust Ball Bearing Solutions

INNO Bearing leverages nearly three decades of manufacturing expertise to deliver exceptional thrust ball bearing solutions for demanding applications. Our comprehensive product range addresses diverse industry requirements with proven reliability.

Our manufacturing capabilities include:

- Custom bearing designs up to φ5000mm outer diameter

- Advanced metallurgy with GCr15, GCr15SIMN, and 20Cr2Ni4A materials

- Precision grinding achieving P5 accuracy grades

- Comprehensive testing protocols ensuring 99.9% quality standards

Quality assurance protocols encompass 12+ performance evaluations including lifespan simulation, vibration analysis, and thermal cycling tests. Our rigorous material inspections utilize spectrometer verification for alloy consistency.

Engineering support includes pre-installation analysis, predictive maintenance solutions, and 24/7 technical assistance. IoT sensor integration provides real-time monitoring capabilities for optimal bearing performance.

Our global supply chain ensures rapid delivery with regional warehouses across EU, Asia, and North America. Emergency replacement programs prioritize urgent requirements with expedited production scheduling.

INNO Bearing's thrust ball bearing portfolio serves critical applications in renewable energy, heavy machinery, mining operations, marine engineering, and aerospace sectors.

Ready to optimize your bearing selection? Our experienced engineering team provides personalized consultation services. Contact Us at sales@inno-bearing.com to discuss your specific requirements. As a leading thrust ball bearing manufacturer, INNO Bearing delivers customized solutions with accelerated delivery timelines and comprehensive technical support.

References

Harris, T.A., and M.N. Kotzalas. "Essential Concepts of Bearing Technology: Rolling Bearing Analysis." 5th Edition, CRC Press, 2006.

Hamrock, B.J., S.R. Schmid, and B.O. Jacobson. "Fundamentals of Fluid Film Lubrication: Machine Elements in Mechanical Design." 2nd Edition, Marcel Dekker, 2004.

ISO 199:2014. "Rolling bearings - Thrust ball bearings - Geometrical product specifications (GPS) and tolerance values." International Organization for Standardization, 2014.

SKF Group Technical Manual. "Rolling Bearings: Thrust Ball Bearings and Thrust roller bearings Design Guidelines." SKF Publications, 2018.

American National Standards Institute. "ANSI/AFBMA 7-1987: Thrust Ball Bearings - Boundary Dimensions and Tolerances." American Bearing Manufacturers Association, 1987.

Tallian, T.E. "Failure Atlas for Hertz Contact Machine Elements: Ball and Roller Bearing Applications." ASME Press, 1999.