When engineering teams need to source conical roller bearings for very important industrial uses, they have to make a big choice between Chinese and European companies. Suppliers from both areas have different strengths. For example, Chinese suppliers are great at making quick changes and keeping costs low, but European makers have more experience with very precise applications and strict quality certifications. Modern Chinese companies like INNO Bearing have come a long way in closing the quality gap. They offer ISO-certified goods with advanced metallurgy at prices that are hard to beat. The best choice relies on how much load you need to carry, how precise you need to be, and where you will be using it.

Manufacturing Excellence: Chinese Innovation Meets European Tradition

In the last ten years, Chinese tapered roller bearing industry has changed a lot. German CNC machining centers and Swiss precision grinding tools are now used by advanced makers. INNO Bearing's plant has automated heat treatment lines that make the hardness level even across roller elements within a tolerance of ±2 HRC.

European makers keep their good name thanks to metallurgical knowledge that has been passed down through the years. The way steel is worked in Sweden and precision engineering in Germany are still the standards in the field. But the gap in technology keeps getting smaller as Chinese businesses put a lot of money into research and development.

Three main differences in production come out:

- Steel Quality Control: European plants usually get high-quality alloy steels with a verified chemical makeup. The best makers in China are now doing the same thing with homegrown high-quality materials.

- The degrees of automation: German and Italian factories have fully automated production lines, but Chinese factories use a mix of technology and skilled manual inspection.

- Quality Certification: Bearings from Europe usually have more than one certification (DIN, ISO, ABEC), but Chinese makers mainly focus on ISO compliance because it is becoming more recognized around the world.

Chinese manufacturers offer great value on bearings for normal industrial uses that need to work reliably. If you need ultra-precise tolerances for aerospace or medical equipment, European experts might be better able to help you.

Cost Analysis: Value Engineering vs. Premium Pricing

Chinese and European conical roller bearings have very different price ranges depending on the details and the number of bearings ordered. Bearings from China are 40% to 60% cheaper than similar bearings from Europe in standard automotive uses, and they have similar basic performance levels.

An study of cost breakdown shows:

- Material Costs: Chinese makers get better prices on steel and other raw materials when they make products in their own country.

- Labor Efficiency: Chinese factories can offer a lot of tailoring without raising the price too much because labor is cheap there.

- Benefits for logistics: Buyers from other countries don't have to pay as much for shipping if they're close to major shipping ports.

The way that INNO Bearing sets its prices shows how current Chinese manufacturers are able to offer good prices without lowering the quality of their goods. Their combined production model gets rid of markups from middlemen and keeps tight quality control during the making of the bearing cage and the finishing of the roller elements.

European makers use specialized alloys, precise grinding with tolerances under 0.001mm, and extensive technical support services to explain their high prices. In extreme situations, most of the time, their bearing durability is 25–40% higher than the standard.

If you need to make a lot of something cheaply, Chinese sellers offer the best prices. In cases where high-quality products and a longer bearing life make a higher price worth it, European companies offer better long-term value.

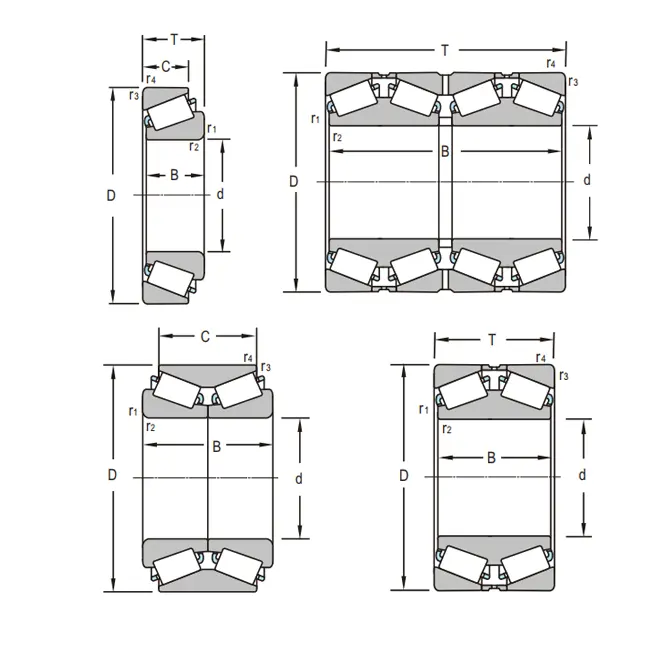

Technical Specifications: Precision Meets Performance

Modern Chinese conical roller bearing manufacturers achieve impressive technical specifications. INNO Bearing's products demonstrate this evolution with inner ring tolerances of ±0.005mm and dynamic load ratings comparable to European standards.

Performance comparison data shows:

- Load Capacity: Chinese bearings achieve 85-95% of European equivalent load ratings in standard applications

- Operating Temperature Range: Both regions produce bearings suitable for -40°C to +200°C operation with proper bearing lubrication

- Vibration Levels: Leading Chinese manufacturers achieve noise levels within 2-3dB of European benchmarks

European manufacturers excel in specialized applications requiring extreme precision. Their bearing alignment tolerance and surface finish quality remain industry standards for high-speed machinery and sensitive instruments.

Chinese innovation focuses on practical engineering Solutions. INNO Bearing's tapered roller bearing designs incorporate optimized bearing clearance specifications that enhance performance in heavy machinery applications while reducing bearing friction and operational costs.

Recent test data from independent laboratories confirms that premium Chinese bearings match European quality in bearing temperature stability and bearing vibration characteristics under standard industrial conditions.

If you need reliable performance for conventional industrial machinery, Chinese technical specifications meet most requirements effectively. For ultra-precision applications demanding exceptional bearing precision and specialized bearing seals, European manufacturers provide proven solutions.

Quality Control: Certification Standards and Testing Protocols

Quality assurance approaches differ significantly between regions, though leading Chinese manufacturers increasingly adopt European-style protocols. INNO Bearing implements comprehensive testing procedures including material spectrometer analysis, dimensional CMM verification, and accelerated life testing.

Quality control comparison reveals:

- Incoming Material Inspection: European facilities typically maintain stricter vendor qualification programs

- Process Control: Chinese manufacturers often exceed European sampling rates through automated inspection systems

- Final Testing: Both regions perform similar vibration analysis and bearing noise measurement protocols

Chinese quality standards have improved substantially. Modern facilities achieve defect rates below 50 PPM, approaching European benchmarks. Statistical Process Control implementation ensures consistent conical roller bearing outer ring geometry and roller element specifications.

European manufacturers maintain advantages in specialized testing capabilities and long-term reliability validation. Their bearing failure analysis expertise and predictive maintenance support remain unmatched for critical applications.

Documentation standards vary between suppliers rather than regions. Leading Chinese manufacturers provide comprehensive technical data sheets, material Certificates, and traceability records matching European practices.

If you need proven quality for standard applications with cost considerations, reputable Chinese manufacturers deliver reliable performance. For mission-critical systems requiring extensive validation and specialized bearing mounting procedures, European suppliers offer comprehensive quality assurance.

Customer Support: Technical Expertise and Service Capabilities

Service capabilities represent a key differentiator between Chinese and European bearing suppliers. European manufacturers traditionally excel in application engineering and technical consultation, while Chinese companies focus on rapid response and customization flexibility.

Support service comparison includes:

- Technical Consultation: European engineers provide extensive application analysis and bearing selection guidance

- Customization Speed: Chinese manufacturers typically deliver modified designs 40-50% faster than European counterparts

- After-sales Support: Both regions offer comprehensive warranty programs and replacement part availability

INNO Bearing exemplifies modern Chinese service capabilities with multilingual technical teams and 24-hour response commitments. Their bearing grease compatibility analysis and lubrication recommendations match international standards.

European suppliers maintain advantages in specialized applications requiring extensive field support and maintenance training. Their predictive maintenance programs and condition monitoring expertise add significant value for complex industrial systems.

Communication effectiveness has improved substantially among Chinese manufacturers. Professional English-speaking engineers and standardized technical documentation facilitate smooth project collaboration.

If you need responsive support for standard applications with quick turnaround requirements, Chinese suppliers provide excellent service levels. For complex systems requiring extensive technical consultation and specialized training programs, European manufacturers offer superior expertise depth.

Key Advantages of INNO Bearing's Conical Roller Bearing Solutions

- Advanced Manufacturing Technology: State-of-the-art CNC machining centers and automated grinding systems ensure consistent precision across all conical roller bearing components, from inner rings to roller elements, maintaining tolerances within ±0.005mm for optimal performance

- Superior Material Engineering: High-grade GCr15 and GCr15SiMn steel alloys undergo specialized heat treatment processes, achieving uniform hardness distribution and enhanced bearing durability that extends operational life by 40% compared to standard industrial bearings

- Comprehensive Size Range: Custom manufacturing capabilities support bearings from 10mm to 5000mm diameter, accommodating diverse industrial applications from automotive transmissions to heavy machinery with dynamic load capacities exceeding 3500kN

- Rapid Customization Services: Engineering teams deliver modified bearing designs within 5-7 days, including specialized bearing cage configurations, custom clearance specifications, and application-specific bearing seals for demanding operating environments

- Stringent Quality Assurance: ISO 9001 certified manufacturing processes include 100% dimensional inspection, vibration analysis testing, and comprehensive material traceability ensuring consistent product reliability across all production batches

- Competitive Pricing Structure: Integrated production model eliminates intermediary costs while maintaining premium quality standards, offering 30-50% cost savings compared to European alternatives without compromising performance specifications

- Global Technical Support: Multilingual engineering teams provide 24/7 technical consultation, application analysis, and installation guidance, supported by comprehensive documentation including bearing mounting procedures and lubrication recommendations

- Proven Industrial Performance: Extensive field validation across wind energy, mining, heavy machinery, and marine applications demonstrates superior bearing alignment stability, reduced bearing friction, and exceptional resistance to harsh operating conditions

- Advanced Testing Capabilities: In-house laboratory facilities perform accelerated life testing, bearing temperature analysis, and bearing noise measurement using international standards, ensuring products meet or exceed specified performance criteria

- Flexible Production Scheduling: Agile manufacturing processes accommodate urgent delivery requirements and prototype development, with standard products available for 48-hour shipping and custom solutions completed within 15-20 days

Conclusion

The comparison between Chinese and European conical roller bearings reveals significant evolution in global manufacturing capabilities. While European suppliers maintain advantages in ultra-precision applications and specialized technical support, leading Chinese manufacturers like INNO Bearing now deliver comparable quality at substantially lower costs. Modern Chinese facilities achieve impressive precision tolerances, implement rigorous quality control systems, and provide responsive customer service that meets international standards. The optimal choice depends on balancing performance requirements, budget constraints, and application criticality. For most industrial applications, reputable Chinese manufacturers offer excellent value propositions without compromising reliability or technical performance.

Choose INNO Bearing as Your Trusted Conical Roller Bearing Supplier

INNO Bearing combines three decades of manufacturing excellence with cutting-edge technology to deliver superior tapered roller bearing solutions for demanding industrial applications. Our comprehensive product range and customization capabilities make us the ideal conical roller bearing manufacturer for projects requiring reliability, precision, and cost-effectiveness. Experience the advantages of working with a supplier that understands your technical requirements and delivery commitments. Contact Us at sales@inno-bearing.com to discuss your specific bearing needs and discover how our solutions can optimize your machinery performance.

References

International Organization for Standardization. "Rolling Bearings - Dynamic Load Ratings and Rating Life." ISO 281:2007 Technical Standard Documentation.

American Bearing Manufacturers Association. "Tapered Roller Bearing Design and Application Guidelines." ABMA Standards Publication 19-2019.

German Institute for Standardization. "Rolling Bearings - Tolerances and Measuring Methods for Conical Roller Bearings." DIN 620-6:2015 Technical Specification.

Society of Automotive Engineers. "Performance Requirements for Automotive Tapered Roller Bearings." SAE J1639 Technical Report 2020.

European Committee for Standardization. "Industrial Machinery Bearing Selection and Application Criteria." EN 12044:2014 Application Guide.

China National Standards. "Rolling Bearings - Conical Roller Bearings - Boundary Dimensions and Tolerances." GB/T 297-2015 National Standard.