To find the load capacity of slewing ring bearings, you need to figure out the highest radial, axial, and moment loads that the bearing can safely handle while it's working. For safety reasons and to make sure the bearing lasts as long as possible in everything from wind turbines to heavy-duty building tools, this calculation uses well-known engineering formulas to look at operational forces and manufacturer specs.

Understanding Load Capacity Fundamentals

The load capacity is the greatest amount of weight that a slewing ring bearing can handle without breaking or shortening its expected lifespan. To understand this aspect, one must know the difference between static and dynamic load capacities, as each is used for different evaluation reasons in bearing selection processes.

Static vs Dynamic Load Ratings

Static load capacity is the most amount of force that a bearing that isn't moving can handle without being permanently damaged. Dynamic load capacity shows how heavy a load can be while the bearing still works for as long as it is expected to under constant spinning. When engineering teams choose bearings for equipment that can change its state, they need to think about both rates. For example, cranes switch between loaded rotation and stationary holding positions.

Essential Load Types and Their Impact

Bearings are mainly affected by three types of loads: radial loads, which push on the bearing at a right angle to its axis; axial loads, which push on the bearing parallel to its axis of rotation; and tilted moments, which cause the load to be spread unevenly across the raceway. Engineers use the equivalent load for capacity estimates. This is based on the combination of these forces.

The load-bearing powers are greatly affected by what the material is made of. For the inner and outer rings, high-quality slewing ring bearings usually use 42CrMo or 50Mn steel, which has a great strength-to-weight ratio. Rolling parts made from GCr15 bearing steel have better fatigue resistance. GCr15SiMn versions are also available that have better impact resistance for tough uses. Nitrile rubber is used in normal conditions, and fluororubber is used in high-temperature conditions. Both seal materials protect the inside parts of the machine while keeping the load capacity intact.

Step-by-Step Calculation Method

Theoretical and real engineering ideas must work together in a planned way to get correct load capacity figures. This method makes sure that the chosen bearings meet both the short-term needs of the work and the long-term expectations of reliability.

Load Identification and Analysis

The first step in the calculation process is a thorough load analysis that records all of the forces acting on the bearing during normal and extreme running conditions. Engineers have to think about environmental factors like earthquakes and wind, equipment weight (static loads), and moves that happen while the machine is working (dynamic loads). Safety factors, which usually fall between 1.5 and 3.0 based on how important the application is, give extra headroom for unexpected changes in load.

Manufacturer Data Integration

Reputable bearing manufacturers base their capacity estimates on the detailed load rating tables they give to their customers. These specs include basic dynamic and static load rates, as well as fatigue load limits that were found through long testing processes. Quality manufacturers such as INNO Bearing do a lot of validation testing, including 500,000+ cycle fatigue analysis, to make sure that the scores they publish really show how well their products work.

Equivalent Load Calculation

Engineers figure out similar loads by adding together individual forces with formulas that take into account the size and direction of the load. The similar dynamic load formula is usually written as P = XFr + YFa + ZM. Here, X, Y, and Z are load factors that depend on how the bearing is designed, Fr is the radial force, Fa is the axial force, and M is the tilting moment. This calculation gives a single number that can be used to compare with manufacturer ratings and figure out if a bearing is suitable.

Real-World Applications and Case Studies

Practical applications demonstrate how load capacity calculations translate into successful bearing selections across diverse industrial sectors. These examples illustrate the importance of matching theoretical calculations with actual operational requirements.

Wind Turbine Yaw System Analysis

Wind turbine yaw bearings face unique challenges from variable wind loads, thermal cycling, and extended maintenance intervals. Load calculations must account for maximum wind speeds, gust factors, and emergency braking forces. A typical 3MW turbine requires slew ring bearings capable of handling axial loads exceeding 5,000kN while maintaining rotational accuracy within strict tolerances. Material selection becomes critical, with advanced seal designs protecting against moisture ingress and temperature variations ranging from -40°C to +80°C.

Mobile Crane Application Example

Mobile crane turntable bearings experience complex loading patterns that combine static loads from counterweights, dynamic loads from boom movements, and impact forces during lifting operations. Load calculations must consider maximum lifting capacity, boom extension lengths, and operational duty cycles. The bearing selection process involves analyzing load duration factors and determining appropriate safety margins to prevent premature failure under varying operational conditions.

These case studies highlight how environmental factors, duty cycles, and maintenance accessibility influence bearing specifications beyond basic load calculations. Successful implementations require close collaboration between equipment manufacturers and bearing suppliers to optimize performance while managing lifecycle costs.

Maintenance Strategies for Optimal Performance

Proper maintenance practices directly impact effective load capacity and service life extension. Understanding these requirements enables procurement teams to specify appropriate bearing configurations and develop comprehensive maintenance protocols.

Lubrication Management

Adequate lubrication keeps the load evenly spread across the moving parts and lowers the friction, which helps prevent damage. Bearing makers base the types, amounts, and replacement times of lubricants on load conditions and working environments. High-quality bearings have improved seal designs that keep the lubricants in and the contaminants out, which keeps the load capacity over long periods of time.

Inspection and Monitoring Protocols

Regular inspection plans find problems before they affect load capacity. Rotational smoothness, noise levels, and temperature changes that show problems are about to happen are monitoring factors. Bearing designs today include features that make it easier to check them while keeping them strong under heavy loads.

Preventive maintenance plans keep the rated load capacity while extending the service life of bearings. Vibration analysis, lubricant sampling, and dimensional testing are usually part of these programs. They look for wear patterns before they impact performance. Advanced tracking systems let you know right away how the slew ring bearings are doing. This lets you plan maintenance ahead of time, which keeps the system running and makes sure that replacements are done at the right time.

INNO Bearing: Engineering Excellence in Heavy-Duty Applications

Luòyáng For tough industrial uses that require high levels of accuracy, INNO Bearing Co., Ltd. uses new technology alongside their almost thirty years of experience in making to make perfectly designed rotating parts. Our wide range of products includes everything from small setups to huge assemblies with outer diameters of up to 4000 mm. This wide range of products meets the needs of many different sectors, including aerospace, mining, wind energy, heavy machinery, and port infrastructure.

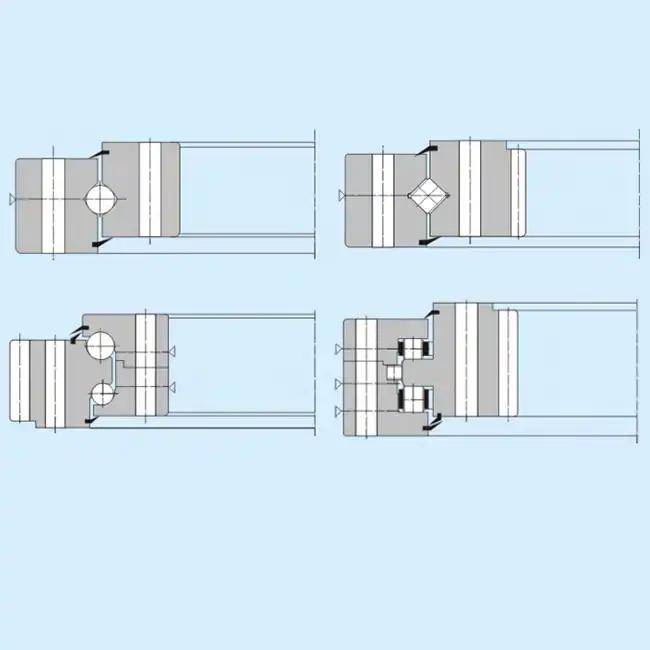

Our technical skills include both ball- and roller-type setups, which can turn all the way around while holding complicated sets of weights. The modular design method uses fixed rings, rotating rings, precision rolling elements, protective cages, and sealing systems that work best for certain conditions. Single-row and double-row rolling element setups make it easier to spread the load, and specialized cage designs keep elements from colliding when there is a lot of load.

Manufacturing greatness is part of how we choose our materials. We use high-quality 50Mn and 42CrMo steels for ring parts and GCr15 steel for bearings to get great fatigue resistance. GCr15SiMn variants that are optional make impact resistance better for tough uses. Nitrile rubber and fluororubber sealing Solutions are available in a range of configurations. Fluororubber is good for environments that need to resist high temperatures and chemicals. These seals help ensure that performance stays high under a variety of conditions while maintaining load capacity even after long service periods.

Conclusion

To figure out the load capacity of slewing ring bearings, you need to know exactly how and where you plan to use them, think about the manufacturer's instructions, and do a detailed study of the forces that will be acting on them when they are in use. Choosing the right bearing relies on knowing the load, using the right math, and thinking about maintenance when you're choosing the specs. The best way to make sure that bearings meet safety standards and last as long as people expect them to is to use both theory math and real-world engineering knowledge. Working with experienced manufacturers gives you access to proven design data and expert help that makes sure the calculations are correct and the project is a success.

FAQs

What factors most affect the load capacity of a slewing ring bearing?

Load types including radial, axial, and tilting moment forces significantly influence capacity, along with bearing size, material quality, lubrication effectiveness, and operating environment conditions. Design elements such as rolling element configuration, raceway geometry, and seal effectiveness also impact load-bearing capabilities.

How often should slewing ring bearings be inspected for load-related wear?

Inspection intervals vary based on application severity, typically ranging from monthly evaluations in heavy-use environments to quarterly assessments for moderate-duty applications. Critical installations may require continuous monitoring through vibration analysis and temperature measurement systems.

Can the load capacity be increased by upgrading to a double-row bearing design?

Double-row bearings generally provide higher load capacity and improved load distribution compared to single-row configurations, making them suitable for heavy-duty applications requiring enhanced radial and axial load support with better moment resistance capabilities.

Partner with INNO Bearing for Superior Load Capacity Solutions

INNO Bearing delivers precision-engineered solutions tailored to your specific load requirements and operational challenges. Our technical team provides comprehensive calculation support, custom design capabilities, and rapid delivery of standard and specialized configurations. With ISO-certified quality systems and extensive testing protocols ensuring 99.9% defect-free delivery, we help optimize your equipment performance while reducing total cost of ownership. Whether you need standard catalog products or custom-engineered solutions, our slewing ring bearing manufacturer expertise ensures reliable performance in your most demanding applications. Contact Us at sales@inno-bearing.com for technical consultation and detailed specifications that meet your project requirements.

References

Harris, Tedric A., and Michael N. Kotzalas. "Rolling Bearing Analysis: Advanced Concepts of Bearing Technology." 5th Edition. CRC Press, 2006.

Palmgren, Arvid. "Ball and Roller Bearing Engineering." 3rd Edition. SKF Industries Inc., 1959.

ISO 281:2007. "Rolling Bearings - Dynamic Load Ratings and Rating Life." International Organization for Standardization.

Eschmann, Paul, Ludwig Hasbargen, and Karl Weigand. "Ball and Roller Bearings: Theory, Design and Application." 2nd Edition. John Wiley & Sons, 1985.

Gentle, Charles R., and Peter W. Pasdari. "Computer Methods in Bearing Design and Analysis." Mechanical Engineering Publications, 1992.

Dowson, Duncan, and C. M. Taylor. "Cavitation in Bearings." Annual Review of Fluid Mechanics, Vol. 11, 1979.